Method for processing scheelite concentrate through sulfuric acid to prepare tungstate solution

A technology of sulfuric acid solution and scheelite, which is applied in the field of tungsten smelting to achieve the effect of reducing energy consumption, easy mass production and stable recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

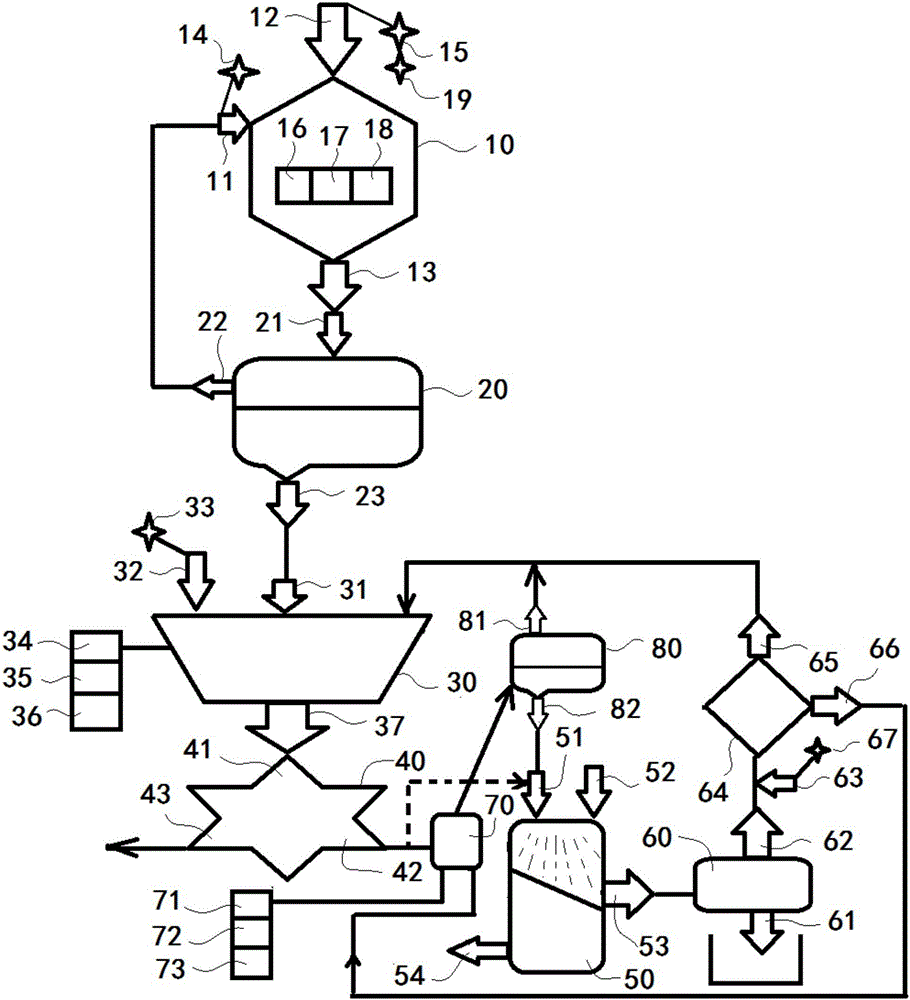

Image

Examples

Embodiment 1

[0065] A scheelite (WO 3 The mass percent content is 52.07%), scheelite and water 1:1 were wet-milled in a vibration mill for 5 minutes, and the particle size was 4 .

[0066] Prepare the ammonium carbonate solution with a final theoretical excess of 100g / L containing 5% NH 3 ·H 2 O, add the above transformation material into the solution, the liquid-solid ratio is 3:1, the temperature is 30°C, react for 2 hours, filter to obtain ammonium tungstate solution, and the tungsten content in the filter residue is <1%.

Embodiment 2

[0068] A scheelite (WO 3 The mass percent content is 52.07%), scheelite and water 1:1.2 were wet-milled in a vibration mill for 5 minutes, and the particle size was 4 .

[0069] Prepare a theoretical concentration of sodium carbonate solution, add the above transformation materials into the solution, the liquid-solid ratio is 3:1, the temperature is 30°C, react for 2 hours, filter to obtain sodium tungstate solution, and the tungsten content in the filter residue is <3%.

Embodiment 3

[0071] A scheelite (WO 3 The mass percent content is 52.07%), scheelite and water 1:1.3 were wet-milled in a vibration mill for 10 minutes, and the particle size was 4 .

[0072] Prepare the final ammonium carbonate solution with a theoretical excess of 150g / L containing 5% NH 3 ·H 2 O, add the above transformation material into the solution, the liquid-solid ratio is 3:1, the temperature is 35°C, react for 1h, and filter to obtain ammonium tungstate solution, the tungsten content in the filter residue is <1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com