Integrative ultrasonic spray pyrolysis large-area wide-temperature zone coating device

A technology of ultrasonic spray pyrolysis and coating device, which is applied in the direction of liquid chemical plating, coating, metal material coating process, etc., which can solve the problems of uneven film formation, difficult control of film formation uniformity, and poor substrate temperature uniformity And other problems, to achieve the effect of uniform film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

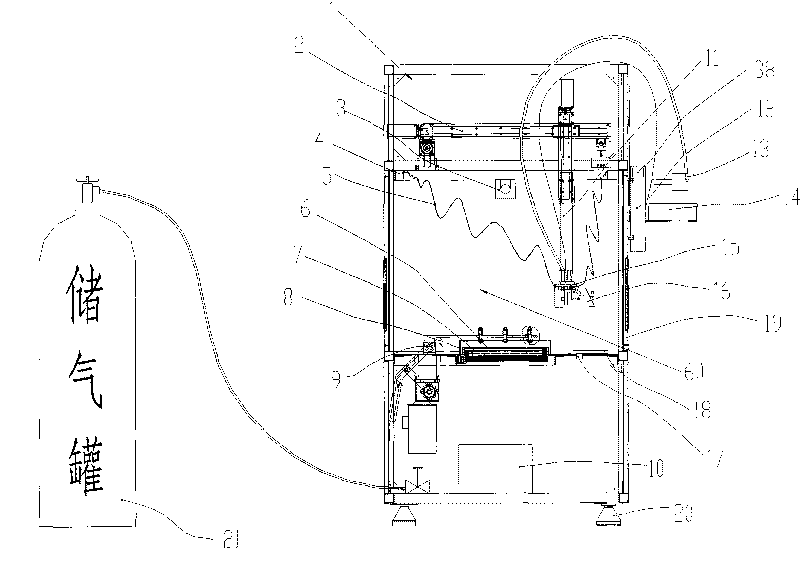

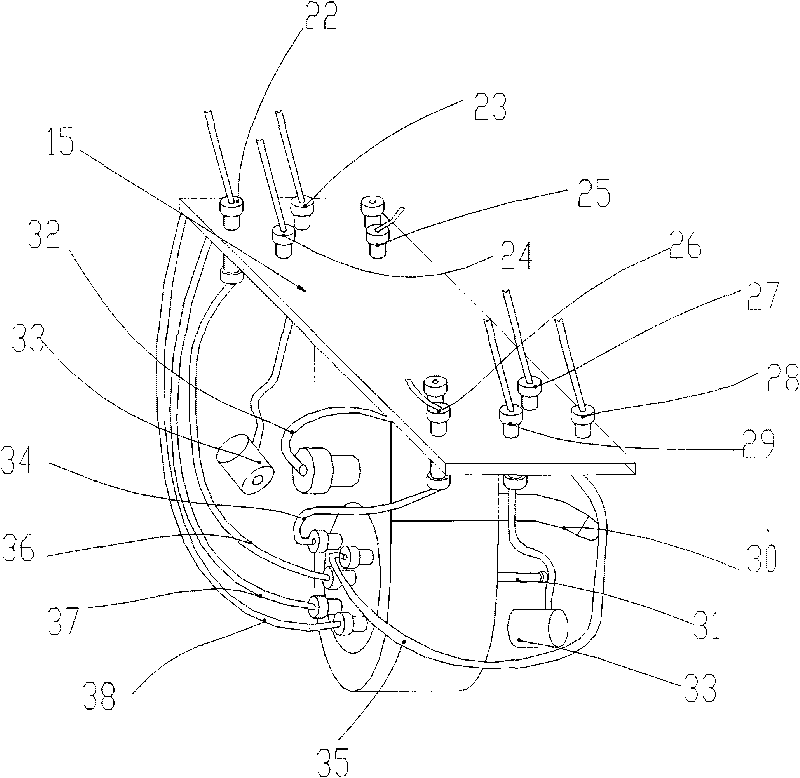

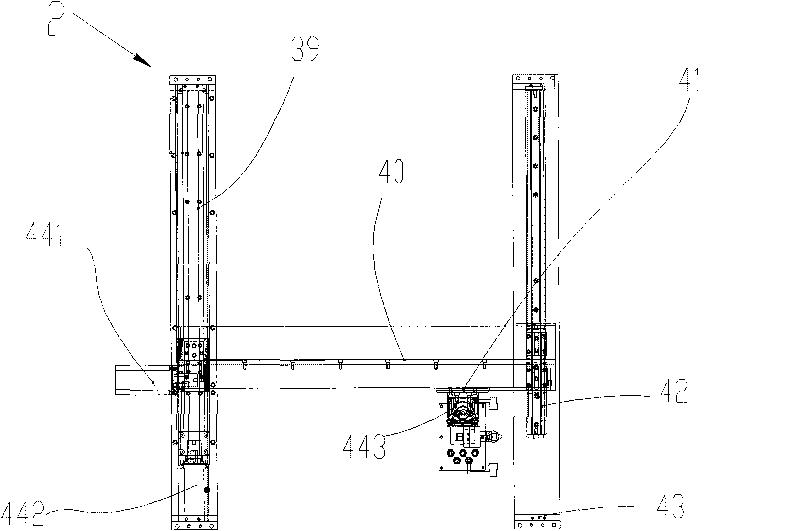

[0028] see figure 1 As shown, the integrated ultrasonic spray pyrolysis large-area wide-temperature zone coating device includes a frame 1, an air storage tank 21, an infusion pump 13 arranged on the frame 1, and a three-dimensional motion mechanism 2 is arranged above the frame 1. And the control module 10 that is used to control this three-dimensional motion mechanism 2 to do three-dimensional motion; In the frame 1, a temperature-controllable heating platform 6 is provided below the three-dimensional motion mechanism 2; There is an integrated ultrasonic atomizing nozzle system capable of high-temperature coating, the integrated ultrasonic atomizing nozzle system faces the heating platform, the infusion pump 13 is connected with the integrated ultrasonic atomizing nozzle system, and the integrated ultrasonic atomizing nozzle system is also connected with the three-dimensional The kinematic mechanism 2 is slidingly connected. The device can already realize the so-called larg...

Embodiment 2

[0049] see figure 1 As shown, the structure and assembly method of the coating device of this embodiment are basically the same as that of Embodiment 1. The difference is that in order to prevent the three-dimensional motion mechanism 2 from being damaged by high temperature and corrosive gases, the workbench 18 below the frame 1 in this embodiment An isolation cover 4 is arranged between the three-dimensional motion mechanism 2, and the isolation cover 4 is fixed along the edge of the transition plate 15. The isolation cover 4, the transition plate 15, the surrounding plates 19 and the workbench 18 around the frame form a deposition chamber 60, and the isolation cover 4 isolates the deposition chamber 60 from the three-dimensional motion mechanism 2, and the isolation cover 4 is made of flexible composite material. A protective cover 16 similar in shape to the spray jet is placed beside the ultrasonic atomizing nozzle 31, and the protective cover can prevent the spray jet fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com