Dual one-dimensional micro-electro-mechanical mirror element

A micro-electro-mechanical and micro-electro-mechanical scanning technology, applied in optical components, instruments, optics, etc., can solve the problems of poor imaging quality, expensive production costs, and adjustment of mirror size to achieve the effect of ensuring clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, structure principle and working principle of the present invention are described in detail:

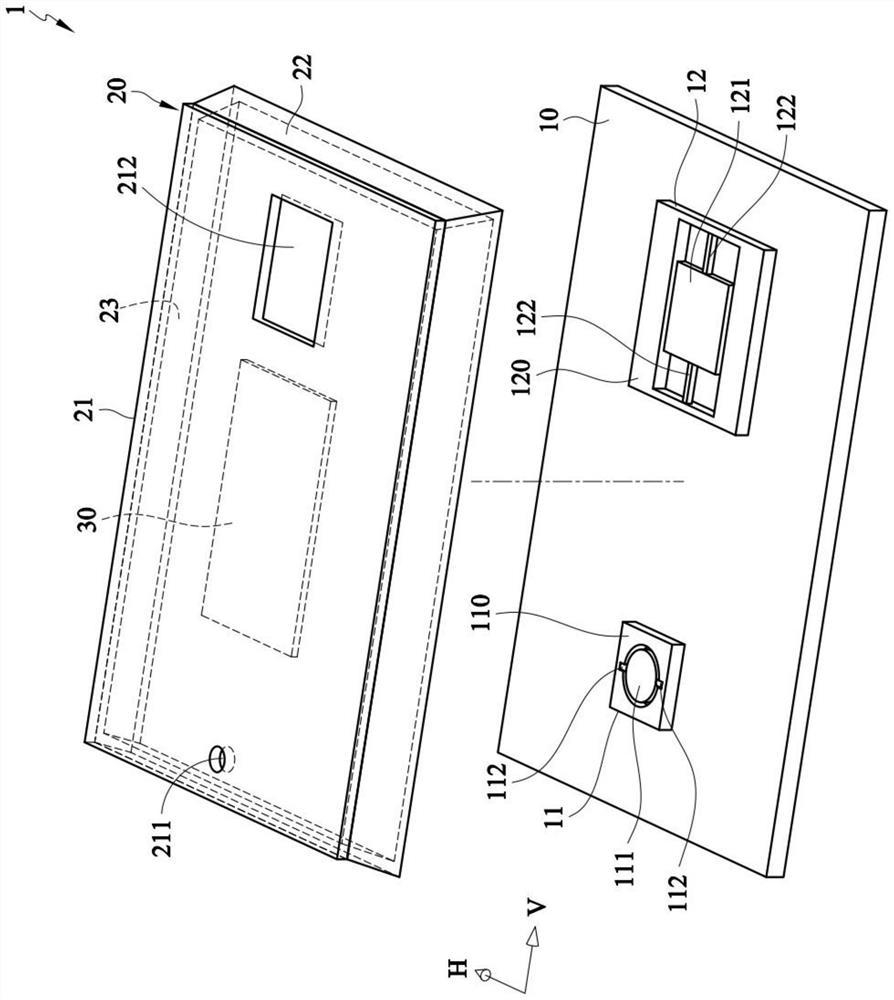

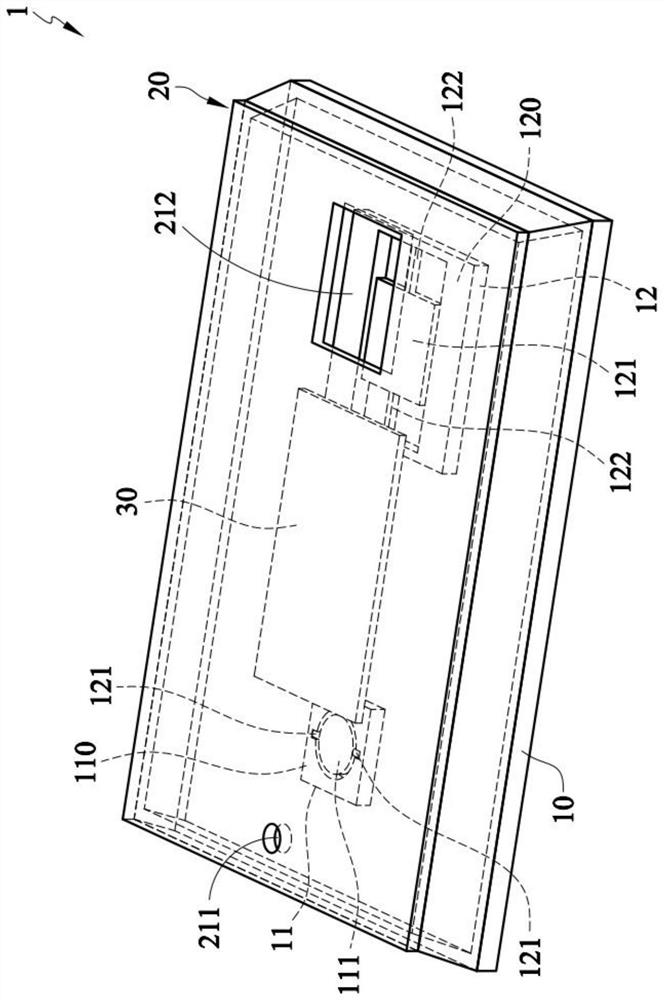

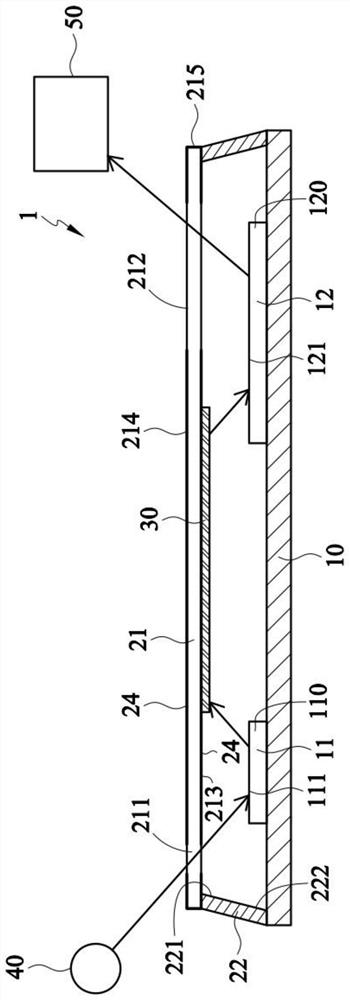

[0038] First see figure 1 As shown, it is the first embodiment of the dual one-dimensional MEMS mirror element 1 of the present invention, which includes a substrate 10, a first one-dimensional MEMS scanning chip 11, a second one-dimensional MEMS scanning chip 12, an upper A cover 20 and a reflective layer 30, wherein the first one-dimensional MEMS scanning chip 11 and the second one-dimensional MEMS scanning chip 12 are welded on the substrate 10, and the upper cover 20 is disposed on the substrate 10 to cover Combined with the first one-dimensional MEMS scanning chip 11 and the second one-dimensional MEMS scanning chip 12 , the reflective layer 30 is disposed on the inner top surface 23 of the upper cover.

[0039] The above-mentioned substrate 10 may be a ceramic substrate, but not limited thereto.

[0040] The above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com