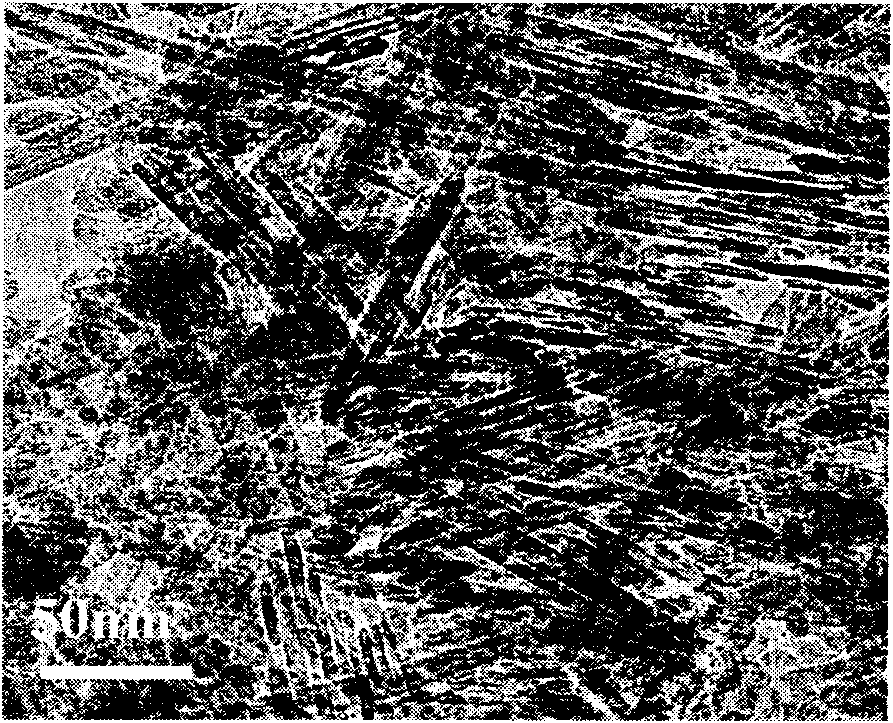

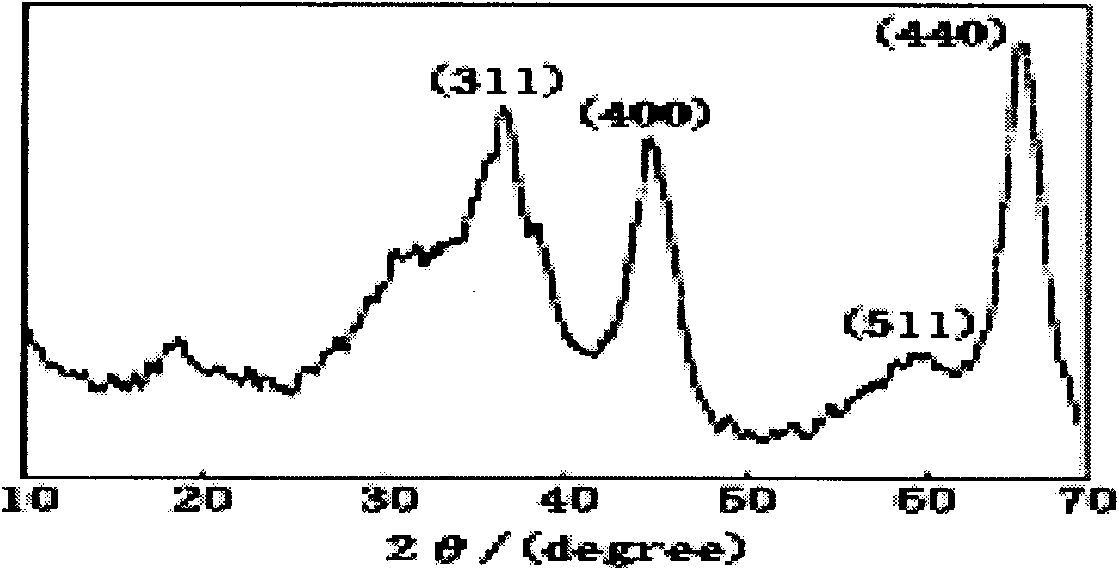

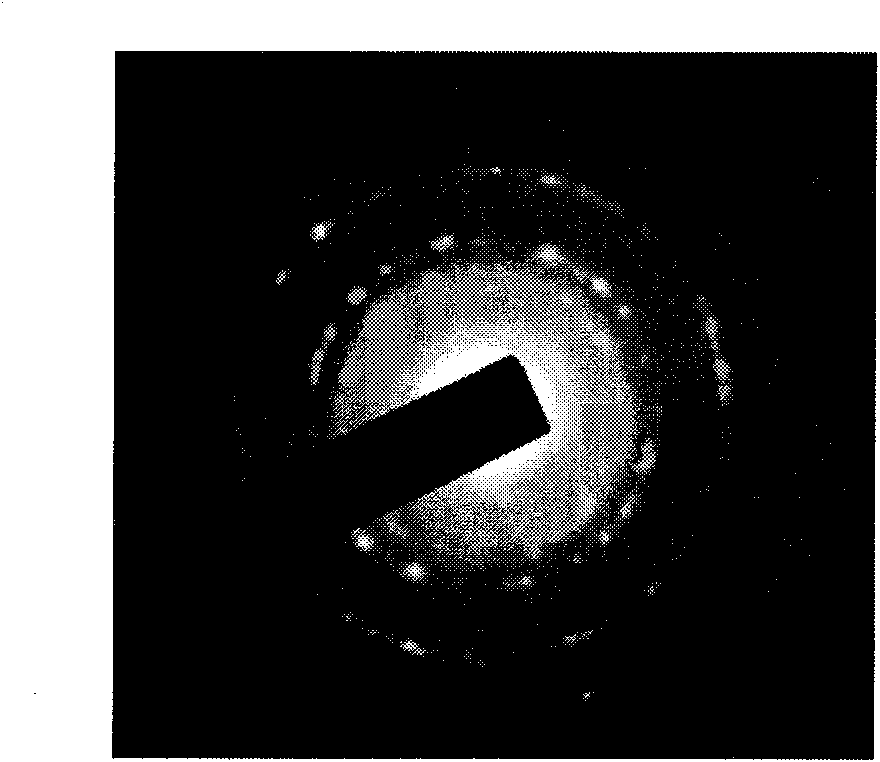

Rod-like one-dimensional polycrystalline gamma-Al2O3 nanocrystal grains and preparation method thereof

A nano-grain and rod-shaped technology, which is applied in the field of rod-shaped one-dimensional polycrystalline γ-Al2O3 nanocrystals and its preparation, can solve the problems of less cation vacancies, adsorption capacity, small specific surface area, application limitations, etc., and achieve high specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare 10ml of 0.3mol / L aluminum chloride aqueous solution and 12ml of 1.0mol / L ammonia solution, and then pour them into a mixed solution containing 10ml of aromatic solvent oil (boiling range is 60-120°C) and 15ml of water under vigorous stirring Add 1.2g of surfactant (containing 0.6g of sodium dodecylbenzenesulfonate and 0.6g of sodium p-styrenesulfonate), and stir vigorously to form a stable emulsion. Ammonia solution and aluminum chloride solution were then slowly added to the above emulsion simultaneously. After the dropwise addition, the mixture was separated into static layers, and the uppermost organic phase was taken out and transferred into a pressure vessel lined with polytetrafluoroethylene, and kept sealed under hydrothermal conditions at 180°C for 48 hours. Cool naturally to room temperature, filter and separate the solid product, dry at 90°C for 8 hours, and finally bake at 550°C for 7 hours to obtain the one-dimensional rod-shaped polycrystalline γ-Al...

Embodiment 2

[0034] Prepare 15 ml of 0.3 mol / L aluminum chloride solution and 20 ml of 0.7 mol / L ammonia solution, and then add 10 ml of paraffin solvent oil (boiling range is 60-90 ° C) and 20 ml of water to the mixed solution under vigorous stirring Add 1.0g surfactant (containing 0.3g sodium dodecylbenzenesulfonate and 0.7g sodium dodecylsulfonate) to the mixture, and stir vigorously to form a stable emulsion. Then the ammonia solution and the aluminum nitrate solution were slowly added to the above emulsion at the same time. After the dropwise addition, the mixture was statically separated into layers, and the uppermost organic phase was taken out and transferred into a pressure bomb lined with polytetrafluoroethylene, and kept at 210°C under hydrothermal conditions for 24 hours, and finally the solid product was filtered and separated, and the solid product was separated at 100 After drying at 550°C for 8 hours, and finally sintering at 550°C for 4 hours, the one-dimensional rod-shape...

Embodiment 3

[0036] Prepare 10 ml of 0.3 mol / L aluminum chloride solution and 12 ml of 1.0 mol / L ammonia solution, and then add 10 ml of chain hydrocarbon solvent oil (boiling range is 60-90 ° C) and 25 ml of water to the mixed solution under vigorous stirring Add 2.4g of surfactant (containing 1.6g of sodium dodecylbenzenesulfonate and 0.8g of sodium xylenesulfonate) to the mixture, and stir vigorously to form a stable emulsion. The sodium hydroxide solution and the aluminum sulfate solution were then slowly added to the above emulsion at the same time. After the dropwise addition, the mixture was statically separated into layers, and the uppermost organic phase was taken out and transferred into a pressure vessel lined with polytetrafluoroethylene, and kept at 240°C under hydrothermal conditions for 24 hours, and finally the solid product was filtered and separated, and the solid product was separated at 120 After drying at 600°C for 8 hours, and finally firing at 600°C for 3 hours, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com