Indirect temperature measuring device in entrained flow gasifying furnace

A technology of temperature measurement device and gasifier, which is applied in the field of indirect temperature measurement device and indirect temperature measurement device in boilers, can solve the problems of many interference factors, time delay, and large error in measurement results, so as to ensure the accuracy of temperature measurement. , Reasonable structure, accurate temperature measurement and real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

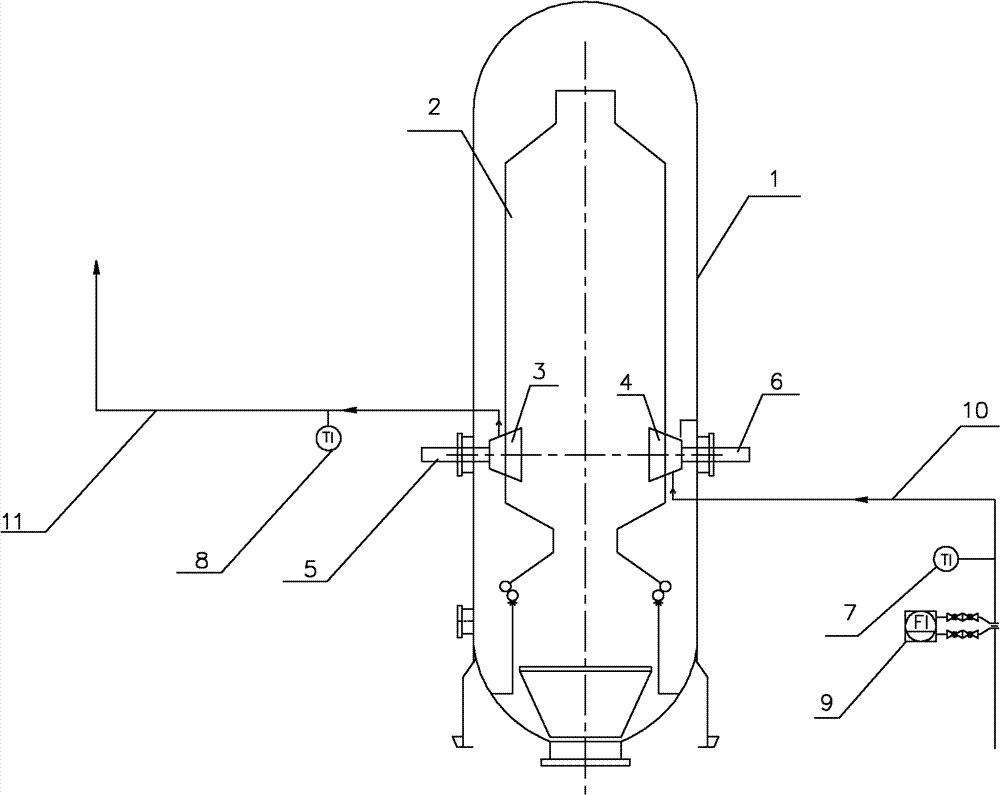

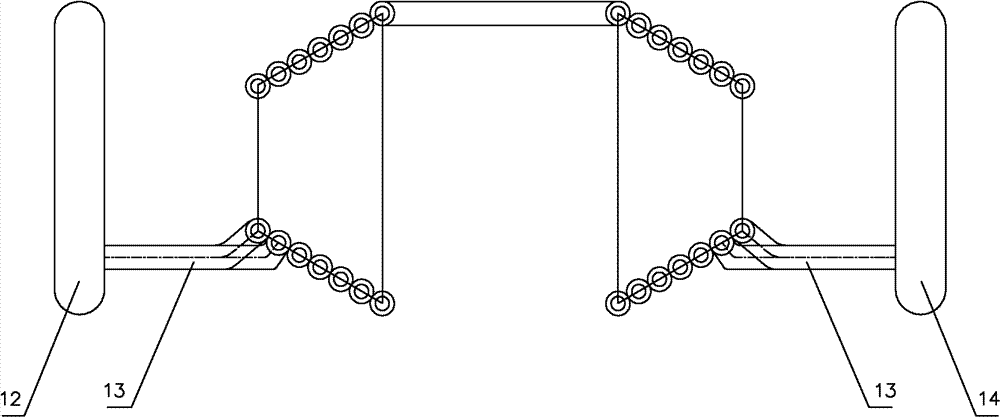

[0018] An indirect temperature measuring device in an entrained bed gasification furnace, including a first nozzle 5 and a second nozzle 6 with the same structure and arranged horizontally on the furnace body 1, both of the first nozzle 5 and the second nozzle 6 run through the furnace body 1, the first nozzle 5 is located at one end of the inner chamber 2 of the furnace body 1 and is connected to the first water cooling cover 3, and the second nozzle 6 is located at one end of the inner chamber 2 of the furnace body 1 and is connected to the second water cooling cover 4, and the first water cooling Both the cover 3 and the second water cooling cover 4 are trumpet-shaped, and one end of the large bell mouth is all towards the center of the body of heater 1. The second water cooling cover 4 is provided with a water inlet pipe 10 on the center axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com