Post-processing hose for engine exhaust gas

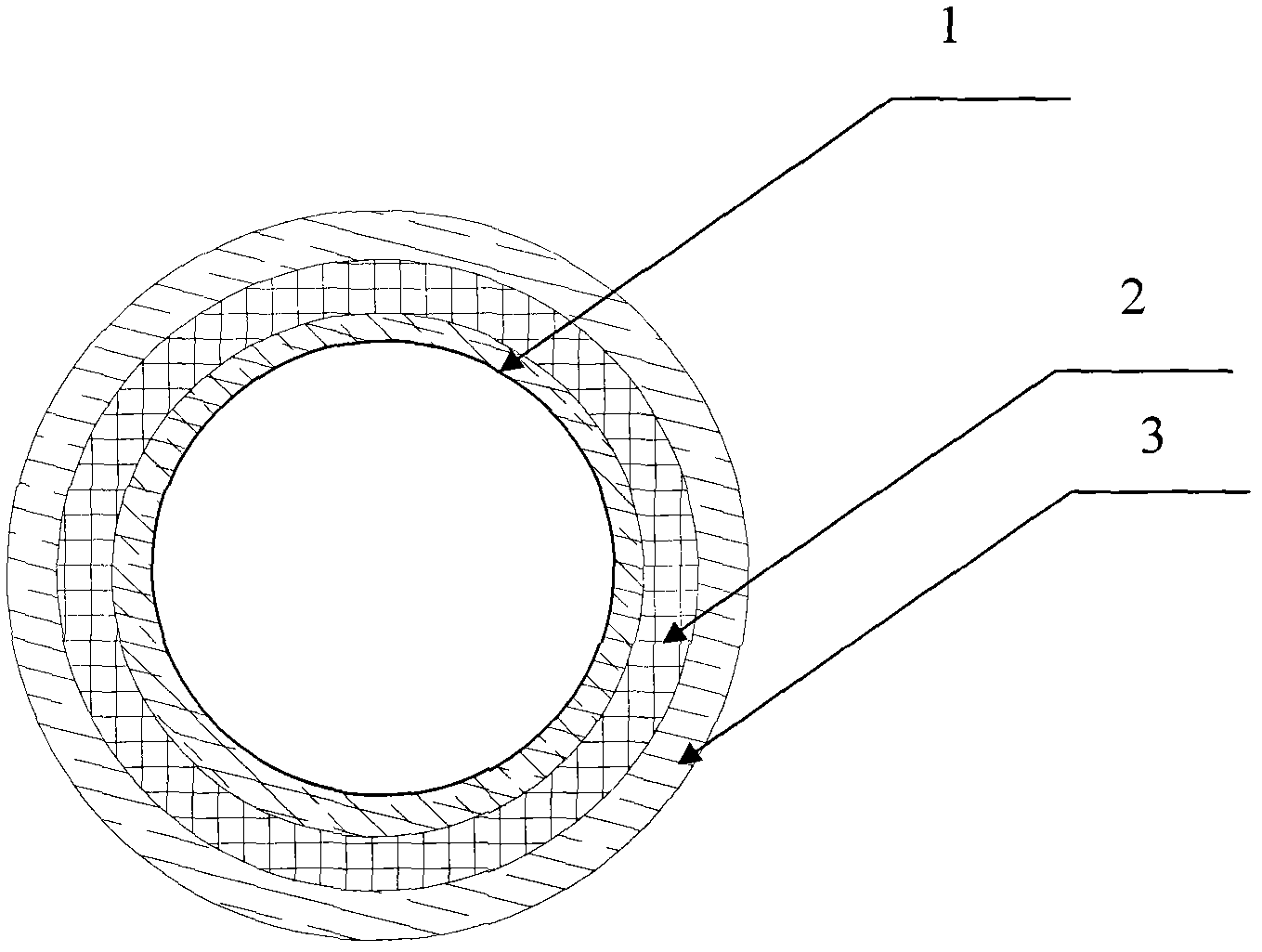

A technology for exhaust aftertreatment and engine, applied in the field of composite hoses, can solve problems such as strong corrosion, and achieve the effects of low cost, strong adhesion and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

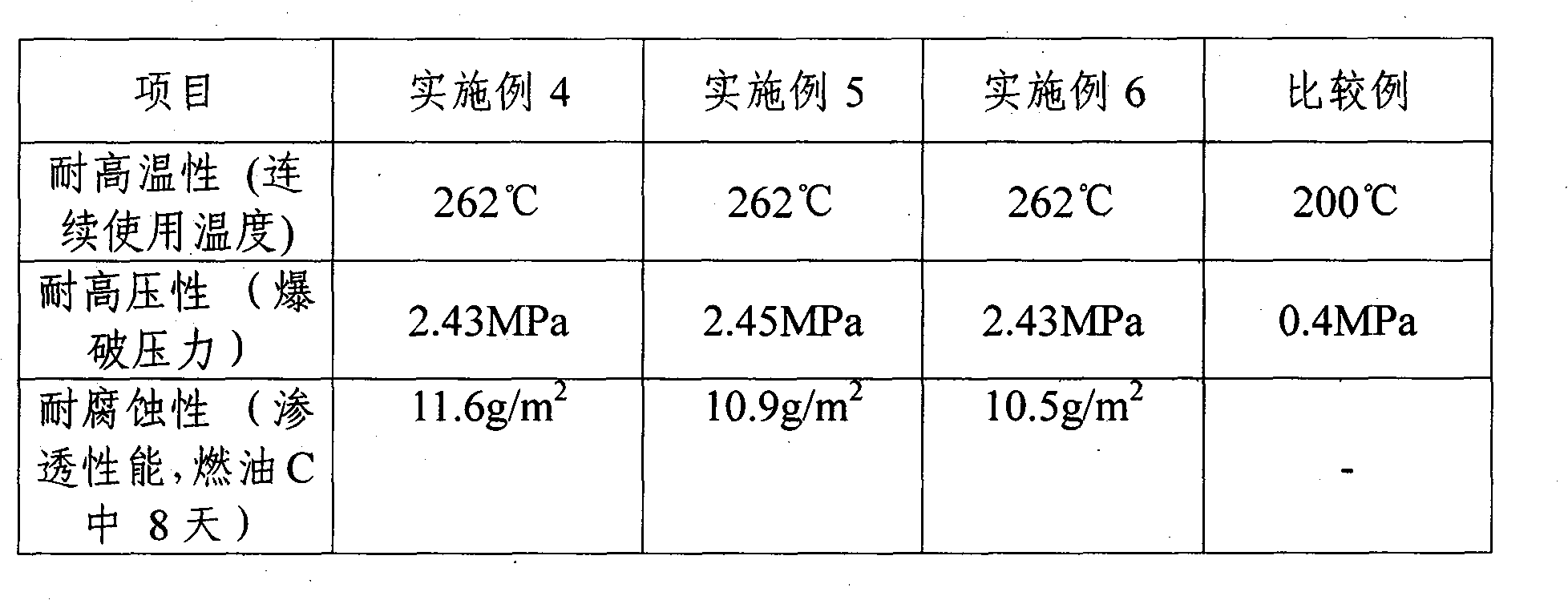

Examples

Embodiment 1

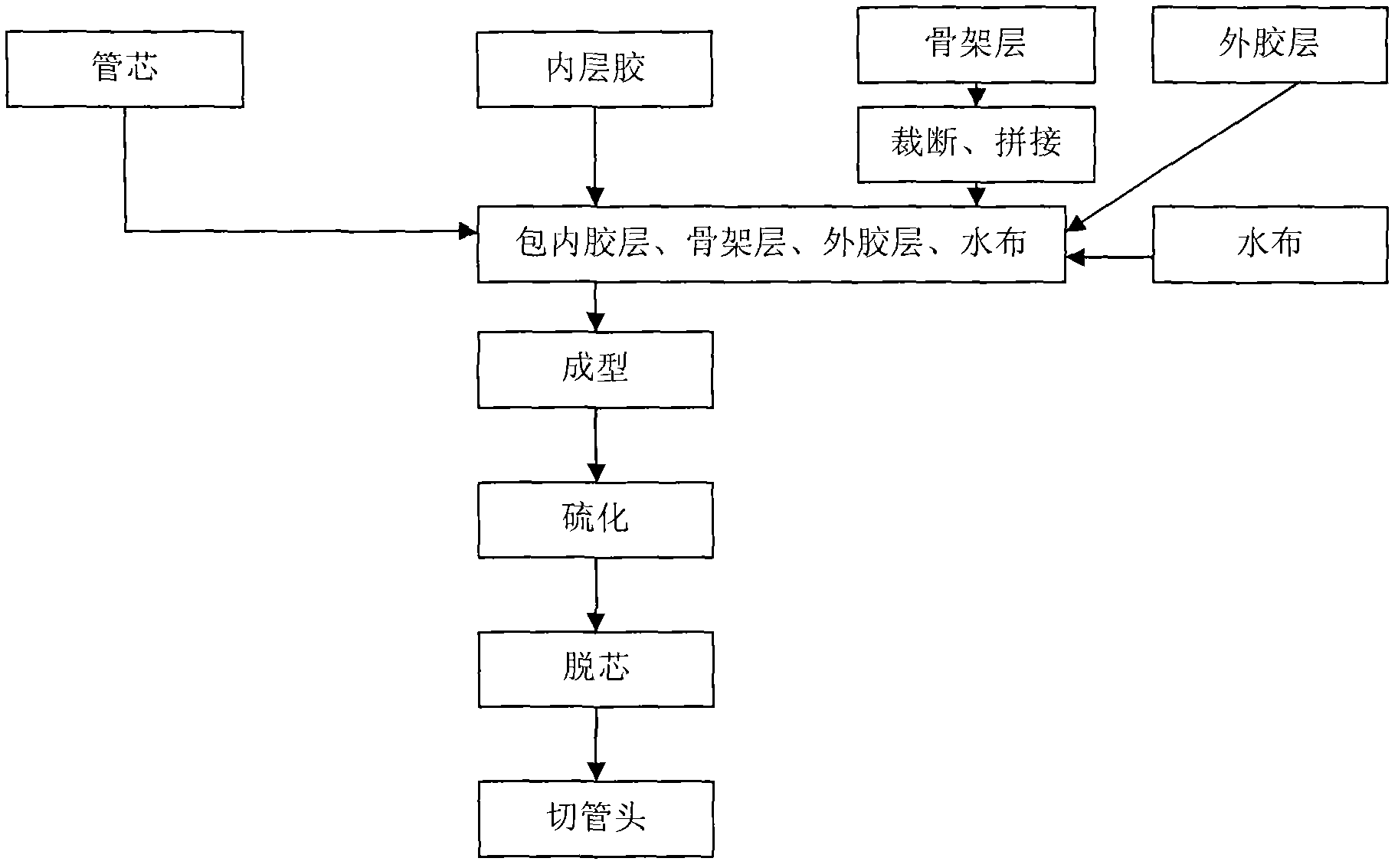

[0043] Embodiment 1: The preparation of the high temperature and high pressure resistant and corrosion resistant engine exhaust aftertreatment hose provided by the present invention comprises the following steps:

[0044] (1), according to the formula: 100 parts by mass of G-type fluororubber, 30 parts by mass of reinforcing filler, 3 parts by mass of peroxide vulcanizing agent, and 3 parts by mass of triallyl isocyanurate, after mixing on the open mill Produce a 5mm film for use;

[0045] (2), according to the formula: 100 parts by mass of silicone rubber, 50 parts by mass of reinforcing filler, 5 parts by mass of structure control agent, 5 parts by mass of heat-resistant additive, 2 parts by mass of peroxide vulcanizing agent, triallyl isocyanurate 3 parts by mass of ester, 5 parts by mass of silane coupling agent, after kneading on an open mill, a film of 5 mm is produced for use;

[0046] (3), according to the formula: 100 parts by mass of silicone rubber, 60 parts by mas...

Embodiment 2

[0059] Embodiment 2: The preparation of the high temperature and high pressure resistant and corrosion resistant engine exhaust aftertreatment hose provided by the present invention comprises the following steps:

[0060] (1), according to the formula: 100 parts by mass of G-type fluororubber, 20 parts by mass of reinforcing filler, 3 parts by mass of peroxide vulcanizing agent, and 3 parts by mass of triallyl isocyanurate, after mixing on the open mill Produce a 10mm film for use;

[0061] (2), according to the formula: 100 parts by mass of silicone rubber, 40 parts by mass of reinforcing filler, 5 parts by mass of structure control agent, 3 parts by mass of heat-resistant additive, 2 parts by mass of peroxide vulcanizing agent, triallyl isocyanurate 2 parts by mass of ester, 2 parts by mass of silane coupling agent, after kneading on an open mill, a film of 10 mm is produced for use;

[0062] (3), according to the formula: 100 parts by mass of silicone rubber, 50 parts by m...

Embodiment 3

[0074] Embodiment 3: The preparation of the high temperature and high pressure resistant and corrosion resistant engine exhaust aftertreatment hose provided by the present invention comprises the following steps:

[0075] (1), according to the formula: 100 parts by mass of G-type fluororubber, 10 parts by mass of reinforcing filler, 3 parts by mass of peroxide vulcanizing agent, and 3 parts by mass of triallyl isocyanurate, after mixing on the open mill Produce a 15mm film for use;

[0076] (2), according to the formula: 100 parts by mass of silicone rubber, 40 parts by mass of reinforcing filler, 5 parts by mass of structure control agent, 2 parts by mass of heat-resistant additive, 2 parts by mass of peroxide vulcanizing agent, triallyl isocyanurate 2 parts by mass of ester, 2 parts by mass of silane coupling agent, after kneading on an open mill, a film of 15 mm is produced for use;

[0077] (3), according to the formula: 100 parts by mass of silicone rubber, 60 parts by m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com