Mesh tubular spring for embolism and preparation method thereof

A tubular, embolization technology, applied in medical science, surgery, etc., can solve the problems of no shape memory function, tumor parent vessel embolism, and lack of good elasticity, so as to achieve good shape memory function, prevent blood vessel embolism, and shorten embolization time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

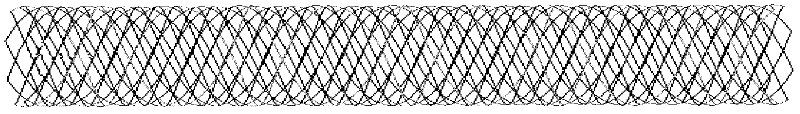

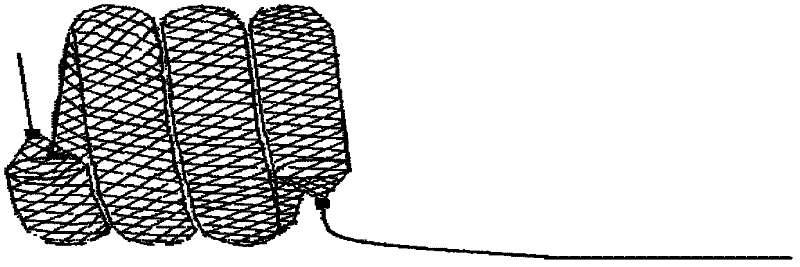

[0023] Example 1, such as figure 1 As shown, the net tubular embolic spring of the present invention is braided into a straight cylindrical net tube by nickel-titanium alloy wire with shape memory function (or called elasticity) and platinum wire developed under X-ray irradiation, such as figure 2 As shown, the straight cylindrical network tube is wound around an axis to form a helical tube to form a network tube-shaped helical coil. The total number of nickel-titanium alloy wires and platinum wires constituting the braided wire is 4 to 72, preferably 8 to 32, and most preferably 16. Nitinol alloy wire is used in the braided wire, so that the spiral tube has the function of memory and restoring the original shape. There is no limit to the number of platinum wires in the total number of braided wires. It is best to add 2 platinum wires in a symmetrical arrangement, so that neither It affects the development of the tubular helical coil under X-ray irradiation, and ensures the ...

Embodiment 2

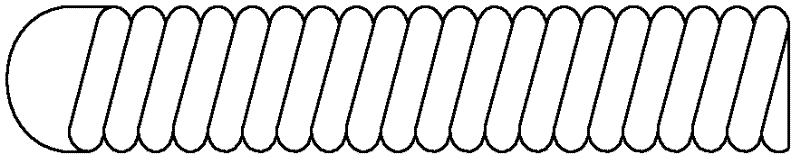

[0038] Embodiment 2, the net tubular helical coil of net tubular embolism spring is non-uniform diameter, as Figure 4 As shown, in the preparation of the non-uniform diameter mesh-shaped helical coil, the middle mandrel and / or the middle size of the metal mandrel is large and the two ends are small, or the middle size is small and the two ends are large, or the middle mandrel and the metal mandrel are large. The diameter of the mandrel changes in the axial direction, so that the network tubes of the tubular helical spring coil are in different sections, and the diameters of the network tubes are not the same. The mesh-shaped helical coils that are finally wound out have different mesh diameters and / or helical diameters in different cross-sections. Depending on the cross-section of the aneurysm, the denser packing of the aneurysmal space by non-uniform diameter tubular embolic coils will be greater. The same method as in Example 1 can be used to deliver the non-uniform diamet...

Embodiment 3

[0039] Embodiment 3, the shape of the net tubular embolism spring is a space network, such as Figure 5 As shown in Fig. 1, the braided straight cylindrical network tube is spiraled onto another space curved metal mandrel mold, and after heat treatment and setting, the middle mandrel and the space curved metal mandrel mold are removed, and the network tube will form a network tube shape consistent with the space surface. Space surface structure. The mesh-shaped embolic spring is more capable of adapting to the aneurysm space, and placing the mesh-shaped embolic spring in the aneurysm can more stably pack the aneurysm. The same method as in Example 1 can be used to send the space-shaped tubular embolic spring into the aneurysm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com