Thin film solid lithium ion secondary battery and manufacturing method thereof

A secondary battery, solid-state lithium technology, applied in the field of lithium-ion batteries, can solve the problems of reduced activity, deterioration of battery characteristics, durability problems, etc., to achieve stable driving, and improve the effect of repeated charge and discharge characteristics and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach (1

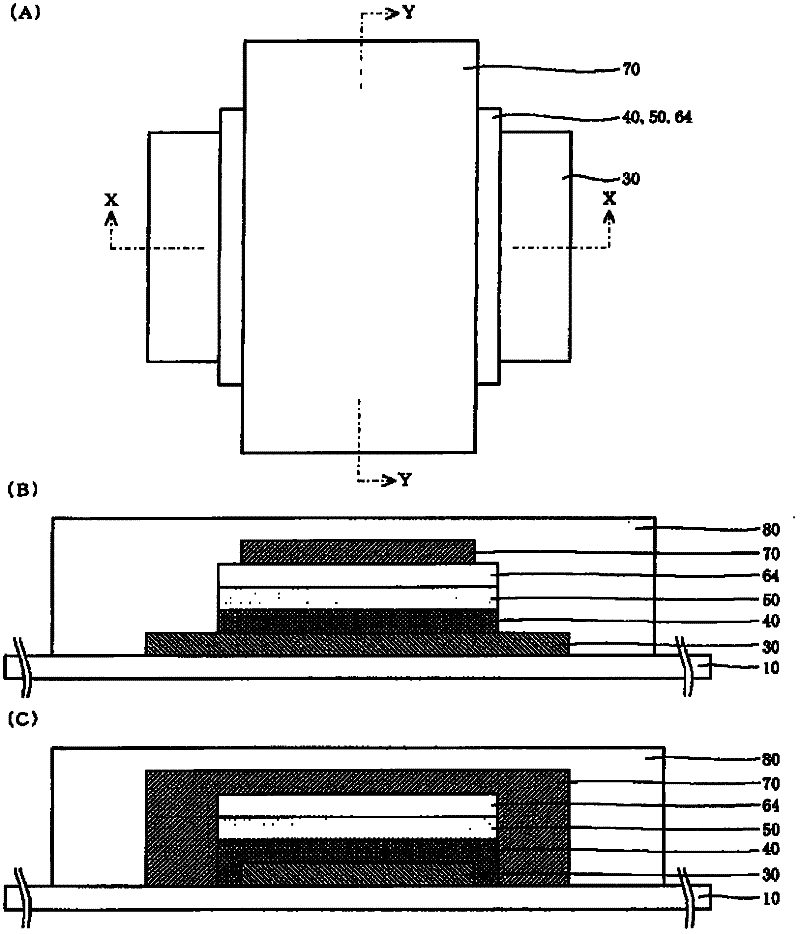

[0095] figure 1 It is a view explaining a schematic structure of a solid-state lithium ion battery in an embodiment of the present invention. figure 1 (A) is a floor plan, figure 1 (B) is the X-X cross-sectional view, figure 1 (C) is a Y-Y cross-sectional view.

[0096] Such as figure 1 As shown, the solid state lithium ion battery has a positive electrode side current collector film 30, a positive electrode active material film 40, a solid electrolyte film 50, a negative electrode potential forming layer 64, and a negative electrode side current collector film 70 are sequentially formed on a substrate (organic insulating Substrate) 10 laminated body. An overall protective film 80 made of, for example, an ultraviolet curable resin is formed to cover the entire laminate.

[0097] figure 1 The battery membrane structure shown in is the substrate / positive electrode side current collector film / positive electrode active material film / solid electrolyte membrane / negative electrode p...

Embodiment approach (2

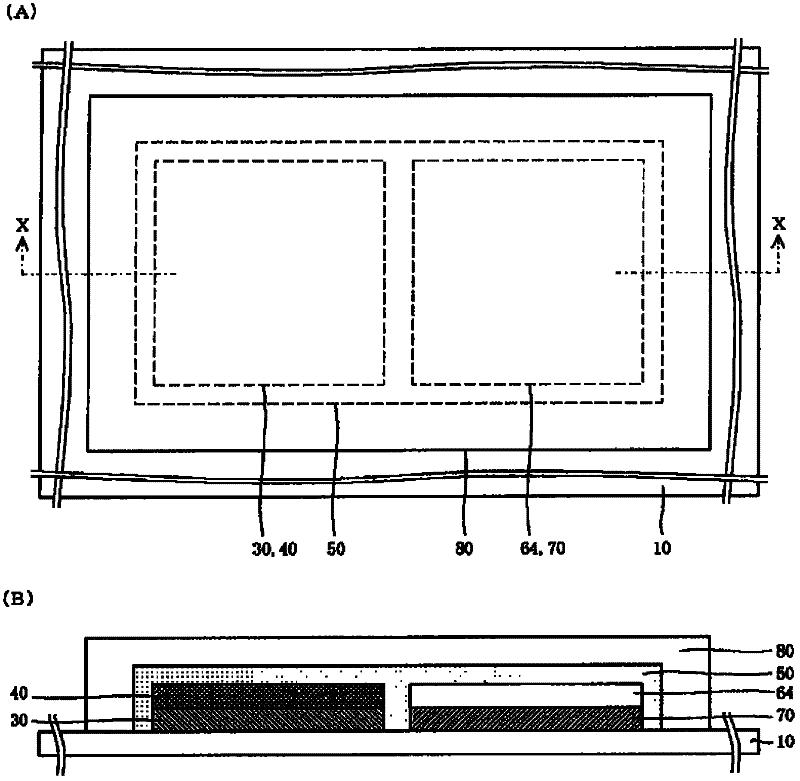

[0101] figure 2 It is a view explaining a schematic structure of a solid-state lithium ion battery in an embodiment of the present invention. figure 2 (A) is a floor plan, figure 2 (B) is an X-X cross-sectional view.

[0102] figure 2 It is a view explaining a schematic structure of a solid-state lithium ion battery in the embodiment (2) of the present invention. figure 2 (A) is a floor plan, figure 2 (B) is an X-X cross-sectional view.

[0103] Such as figure 2 As shown, the solid-state lithium ion battery includes a laminate formed on a substrate (organic insulating substrate) 10 consisting of a positive electrode side current collector film 30 and a positive electrode active material film 40, and a negative electrode side current collector film 70 and a negative electrode potential. Layer 64 is a laminate. The solid electrolyte film 50 is formed to entirely cover the above-mentioned two laminates arranged in a straight line on the substrate (organic insulating substrate) ...

Embodiment approach (3

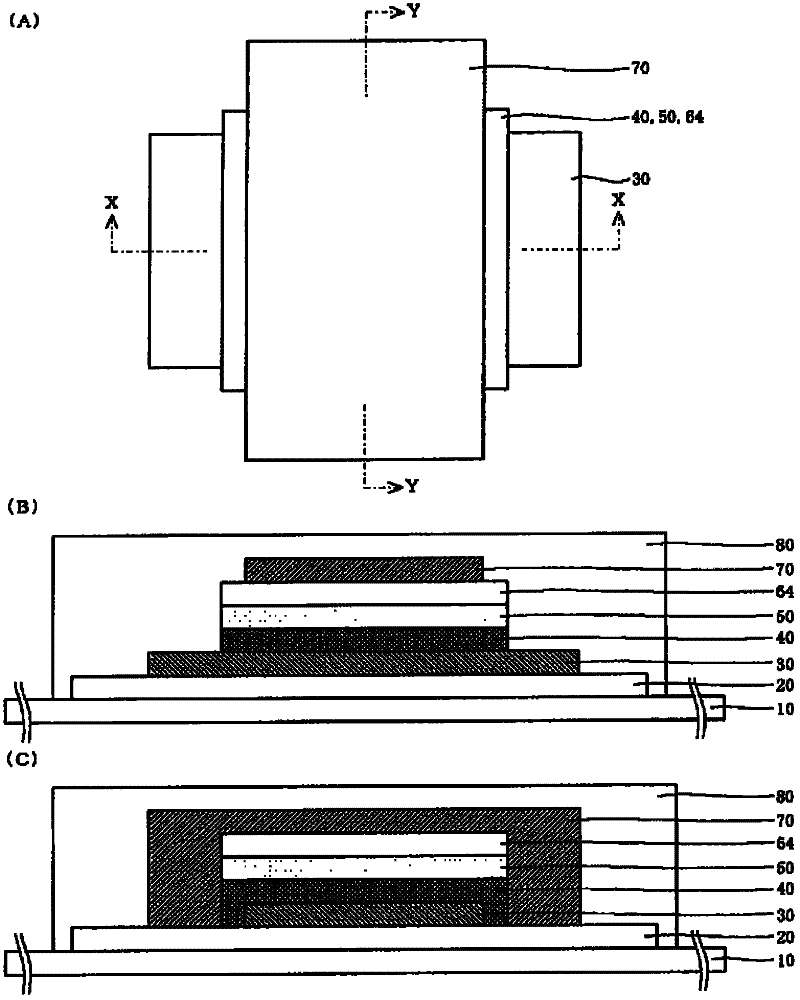

[0107] image 3 It is a view explaining a schematic structure of a solid-state lithium ion battery in an embodiment of the present invention. image 3 (A) is a floor plan, image 3 (B) is the X-X cross-sectional view, image 3 (C) is a Y-Y cross-sectional view.

[0108] Such as image 3 As shown, the solid-state lithium ion battery has an inorganic insulating film 20 formed on the surface of a substrate (organic insulating substrate) 10. The solid state lithium ion battery has a stack in which a positive electrode side current collector film 30, a positive electrode active material film 40, a solid electrolyte film 50, a negative electrode potential forming layer 64, and a negative electrode side current collector film 70 are sequentially formed on the inorganic insulating film 20 body. An overall protective film 80 made of, for example, an ultraviolet curable resin is formed to entirely cover the laminate and the inorganic insulating film 20.

[0109] image 3 The battery film st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com