Polyolefin resin composition

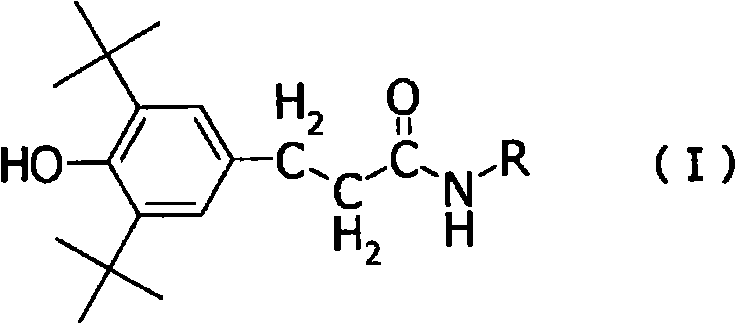

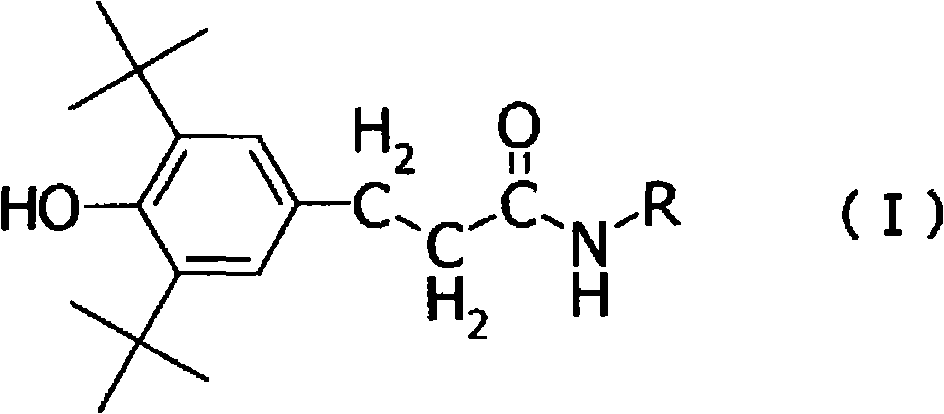

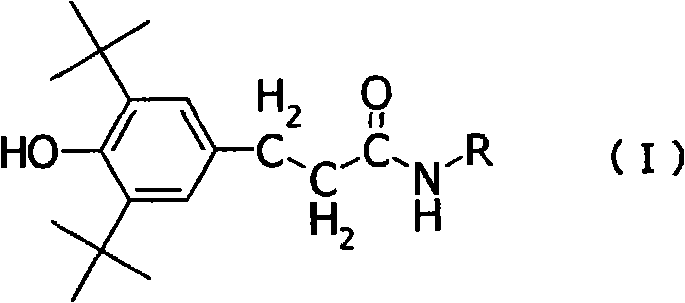

A technology of polyolefin resin and composition, applied in the field of polyolefin resin composition, can solve the problems of poor dispersion, lack of thermal and light stability, and inability to obtain life, and achieve the effect of inhibiting the generation of gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] According to the following procedure ([1] Preparation of catalyst slurry, [2] Preparation of phenate solution, [3] Preparation of phosphite solution, [4] Polymerization of olefin-based monomer), a polyolefin-based resin was obtained combination.

[0062] [1] Preparation of catalyst slurry

[0063] 4.76 g (50 mmol) of anhydrous magnesium chloride, 25 mL of decane, and 23.4 mL (150 mmol) of 2-ethylhexanol were added, and the reaction was heated at 130° C. for 2 hours to prepare a homogeneous solution, and then 1.11 l of phthalic anhydride was added. g (7.5 mmol) was stirred for 1 hour while maintaining at 130°C to dissolve phthalic anhydride in this homogeneous solution. Next, the homogeneous solution was cooled to room temperature, and the entire amount was dropped into 200 mL (1.8 mol) of titanium tetrachloride maintained at -20°C over 1 hour. After the charging was completed, the temperature was raised to 110°C over 4 hours. After reaching 110°C, 2.68 mL (12.5 mmol)...

reference example 1

[0073] Polymerization was carried out in the same manner as in [4] of Example 1, except that 1.4 mL of the phenate solution and 0.7 mL of the phosphite solution were not used for the polymerization of the olefin-based monomer in the above-mentioned Example 1. Polyolefin resin composition. Next, tris(2,4-di-tert-butylphenyl)phosphite and tetrakis[methylene-3-(3,5-di-tert-butyl-4'-hydroxyphenyl)propionate]methane 500 ppm each was mixed with the obtained polyolefin-based resin, and pelletized by a single-screw extruder (device: PLASTOMILL, manufactured by Toyo Seiki Co., Ltd., extrusion temperature: 230° C., screw rotation speed: 50 rpm) to obtain pellets .

[0074] (Evaluation of stabilization effect)

[0075] With respect to the polyolefin-based resin composition or pellets obtained by the above method, the single-screw extruder (device: PLASTOMILL, manufactured by Toyo Seiki Co., Ltd., extrusion temperature: 280° C., screw rotation speed: 50 rpm) was repeated for 5 The seco...

Embodiment 2

[0084] According to the following procedure ([1] Preparation of catalyst slurry, [2] Preparation of phenate solution, [3] Preparation of phosphite solution, [4] Polymerization of ethylene), a polyethylene resin composition was obtained.

[0085] [1] Preparation of catalyst slurry

[0086] 31.2 g (273 mmol) of diethoxymagnesium, 41.2 g (136 mmol) of tributoxytitanium chloride, and 10.1 g of n-butanol were added to the nitrogen-substituted flask, and the reaction was carried out by heating at 150° C. for 6 hours to obtain a uniform solution. The solution was then cooled to room temperature, and 200 mL of n-heptane was added. Next, the temperature was raised to 40° C., 20.6 g (82.6 mmol) of ethyl aluminum sesquichloride was added dropwise, and the mixture was stirred for 1 hour and reacted.

[0087] After the completion of the reaction, the solid titanium catalyst component (Ziegler catalyst) was obtained by sufficiently washing with n-heptane until the free titanium compound co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com