Controlling microbial contamination in alcoholic fermentation processes

A technology of microbial pollution and ethanol fermentation, which is applied in the direction of fermentation, biofuel, and growth stimulation by adding compounds, which can solve the problems of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

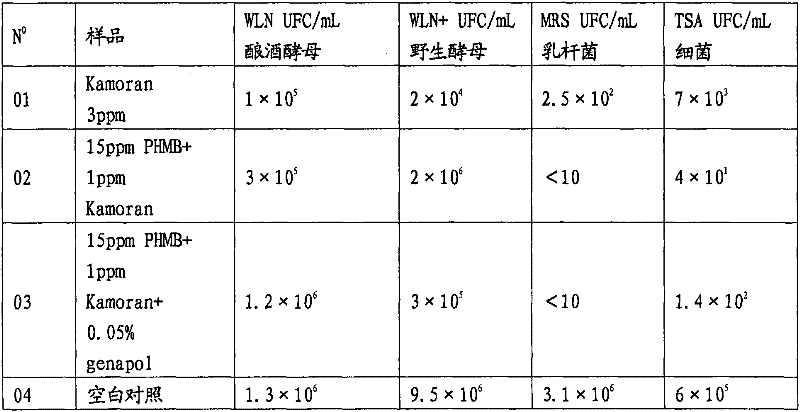

Examples

Embodiment Construction

[0025] One of the above general objects can be achieved by providing an antimicrobial composition comprising: from about 1% to about 5% by weight of an antimicrobial agent of the guanidine family, such as polyhexaformin (PHMB); from about 0.05% to about 0.5% by weight biocide; and from about 98.95% to about 94.5% by weight surfactant.

[0026] Biocides are usually selected based on the characteristics of the fermented juice and the microflora of contaminating microbial contaminants found in said juice, as well as the environment of the raw material before it was added to the fermenter.

[0027] With regard to the fermentation of sugar cane juice ("garapa"), the antibiotic used to form the antimicrobial composition of the present invention may be an ionophore selected from the group consisting of virginiamycin, penicillin, penicillin V, clindamycin, alanine Acids, beta-lactams, tetracyclines and preferably monensins, known antibiotics from the company Elanco under the trade nam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com