Pulverized coal decoupling combustor and decoupling combustion method thereof

A combustion method and burner technology, which is applied in the direction of combustion method, burner, burner for burning powder fuel, etc., can solve the problem of unadjustable coal concentration separation performance, unsuitable for furnace structure, and difficult to realize decoupling large-scale combustion furnace To achieve the effects of stable combustion, suppressing the formation of NOx, increasing the temperature, and increasing the entrainment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The pulverized coal decoupling burner and decoupling combustion method of the present invention will be further described below.

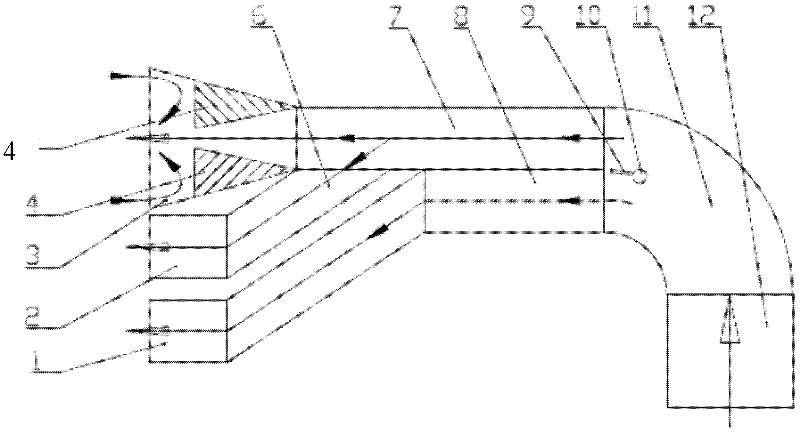

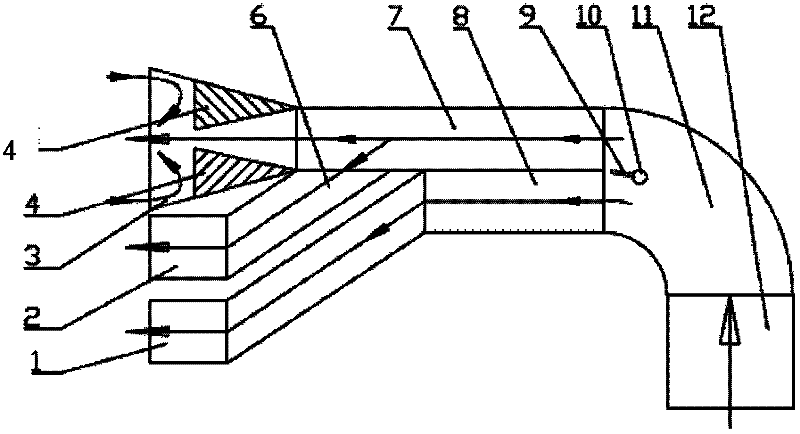

[0051] The pulverized coal decoupling burner provided by the invention, such as figure 1 As shown, it consists of a plurality of burner nozzles and an inertial separator connected to the burner nozzles through conduits; along the airflow direction from front to rear, there are inertial separators, conduits and burner nozzles in sequence.

[0052] The plurality of burner nozzles are respectively three-stage nozzles 1, two-stage nozzles 2 and one-stage nozzles 3; the three-stage nozzles 1 communicate with the inner side of the rear end of the inertial separator 11 through the light side airflow conduit 8; The secondary nozzle 2 communicates with the inside of the rich-side airflow conduit 7 through the secondary nozzle conduit 6 ; the primary nozzle 3 communicates with the outside of the rear end of the inertial separator 11 through the rich-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com