Hollow column member with built-in high tensile steel bars and pipes for confinement of ultra high performance concrete

An ultra-high-performance, reinforced steel pipe technology, applied in the field of pier and column components, can solve the problems of light weight and high-strength performance that need to be further improved, insufficient strength of ordinary steel bars and concrete, and excessively large cross-sectional area of components, so as to increase the available space. , the effect of overcoming excessive brittleness and insufficient ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

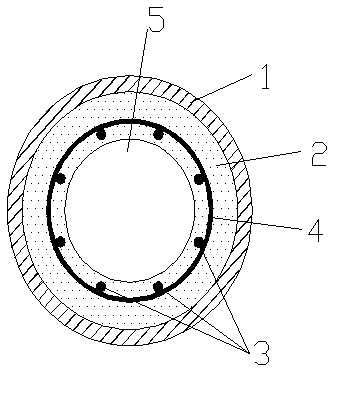

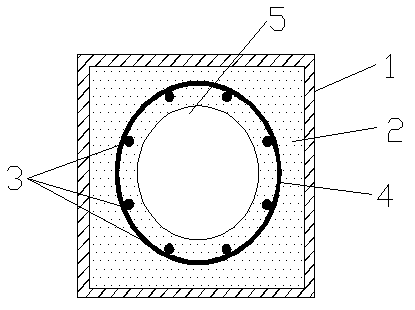

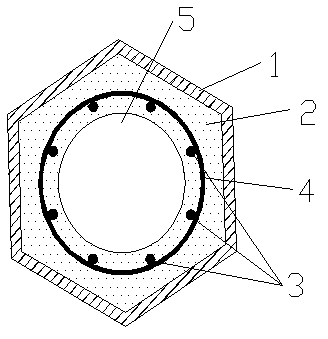

[0034] As shown in the figure, an ultra-high-performance concrete hollow column member with built-in high-strength reinforced steel pipes constrained, which includes an outer steel pipe 1, a steel skeleton inside the outer steel pipe, and a cavity ultra-high performance concrete 2 poured on the inner surface of the outer steel pipe to wrap the steel skeleton; The steel skeleton is composed of longitudinal steel bars 3 and stirrups 4, and the stirrups 4 are placed outside the longitudinal steel bars 3 to form a closed ring that limits the displacement of the longitudinal steel bars 3; a cavity 5 is left in the middle of the member; the longitudinal steel bars 3 Adopt high-strength steel bars, and described stirrup 4 adopts high-strength steel bars or common steel bars;

[0035] The high-strength steel bars mentioned above refer to steel bars with a yield strength of 500 MPa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com