Combination system of oil shale bubbling bed dry distillation and semi-coke circulating fluidized bed combustion

A circulating fluidized bed and combined system technology, used in special forms of dry distillation, direct heating dry distillation, coke ovens, etc., can solve the problems of poor gas quality, waste of resources, waste of shale oil resources, etc., and achieve high economy and quality. , the effect of reducing energy loss and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

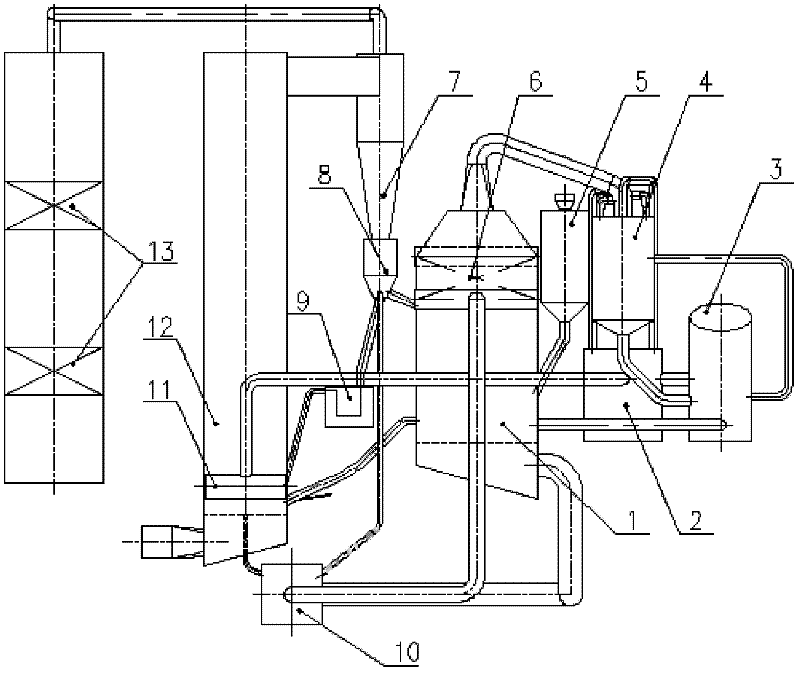

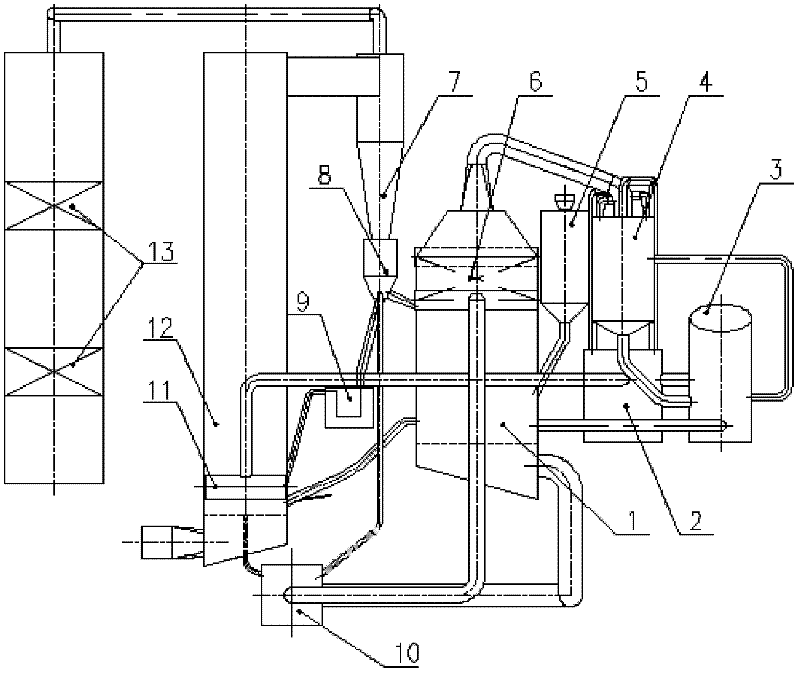

[0021] Oil shale bubbling bed dry distillation and semi-coke circulating fluidized bed combustion combined system, its structure is as follows figure 1 As shown, the combined system includes bubbling bed 1, gas storage tank 2, oil-water separator 3, gas-liquid separator 4, oil shale bunker 5, circulating gas heat exchanger 6, gas-solid separator 7, shale ash Bin 8, return valve 9, external gas-solid heat exchanger 10, gas burner 11, circulating fluidized bed 12, tail heating surface 13, the connection method of each component of the system is: oil shale bin 5 outlet and bubbling The oil shale inlet of bed 1 is connected, the overflow port of bubbling bed 1 is connected with the semi-coke inlet of circulating fluidized bed 12, the upper outlet of bubbling bed 1 is connected with the flue gas inlet of circulating gas heat exchanger 6, and the circulating gas heat exchanger 6 The flue gas outlet is connected to the gas-liquid separator 4 inlet, the gas outlet of the gas-liquid se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com