A kind of preparation method of zirconium phosphorus fluorine-free opacity glass

A technology of opacity glass and zirconium phosphorus, which is applied in the field of preparation of zirconium phosphorus fluorine-free opacity glass, can solve the problems of uneven opacity of opacity glass and low phase separation ability of phosphorus, and achieve fine structure, good texture, avoid The effect of uneven phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of zirconium phosphorus fluorine-free opaque glass, it comprises the following steps:

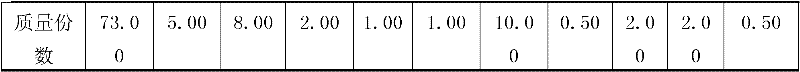

[0024] 1) The basic composition range of the zirconium phosphorus fluorine-free opaque glass used in the present invention is shown in Table 1-1:

[0025] Table 1-1 (mass parts)

[0026]

[0027]

[0028] The clarifying agent is Sb 2 o 3 .

[0029] Calculate the ingredients based on the content of the components in Table 1-1, and obtain the ingredient list. Use mineral raw materials and chemical raw materials to introduce various oxides, in which phosphorus pentoxide and zirconium oxide are respectively introduced by calcium hydrogen phosphate and zirconium oxide. And carry out weighing, mixing, obtain glass batch material.

[0030] See Table 1-2 for the ingredient list of zirconium phosphorus fluorine-free opaque glass raw materials.

[0031] Table 1-2 Glass Raw Material Ingredients List

[0032] raw material

Purity (mass%)

Dosage (m...

Embodiment 2

[0039] A preparation method of zirconium phosphorus fluorine-free opaque glass, it comprises the following steps:

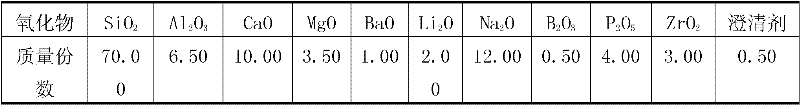

[0040] 1) Selection of raw materials: The basic composition range of the zirconium phosphorus fluorine-free opaque glass used in the present invention is shown in Table 2-1:

[0041] Table 2-1 (mass parts)

[0042]

[0043] The clarifying agent is Sb 2 o 3 .

[0044] Calculate the ingredients based on the component contents in Table 2-1, and obtain the ingredient list. Use mineral raw materials and chemical raw materials to introduce various oxides, among which phosphorus pentoxide and zirconium oxide are respectively introduced by calcium hydrogen phosphate and zirconium oxide. And carry out weighing, mixing, obtain glass batch material.

[0045] See Table 2-2 for the ingredient list of zirconium phosphorus fluorine-free opaque glass raw materials.

[0046] Table 2-2 Glass Raw Material Ingredients List

[0047] raw material

Purity (mass%) ...

Embodiment 3

[0055] A preparation method of zirconium phosphorus fluorine-free opaque glass, it comprises the following steps:

[0056] 1) Selection of raw materials: The basic composition range of the zirconium phosphorus fluorine-free opaque glass used in the present invention is shown in Table 3-1:

[0057] Table 3-1 (mass parts)

[0058]

[0059] The clarifying agent is Sb 2 o 3 .

[0060] Calculate the ingredients based on the component contents in Table 3-1, and obtain the ingredient list. Use mineral raw materials and chemical raw materials to introduce various oxides, among which phosphorus pentoxide and zirconium oxide are respectively introduced by calcium hydrogen phosphate and zirconium oxide. And carry out weighing, mixing, obtain glass batch material.

[0061] See Table 3-2 for the ingredient list of zirconium phosphorus fluorine-free opaque glass raw materials.

[0062] Table 3-2 Glass Raw Material Ingredients List

[0063] raw material

Purity (mass%) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com