PU (Poly Urethane)-leather wastewater-processing method

A wastewater treatment and wastewater technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Problems such as low process efficiency, to achieve the effects of large water quality fluctuations, reduced operating costs, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

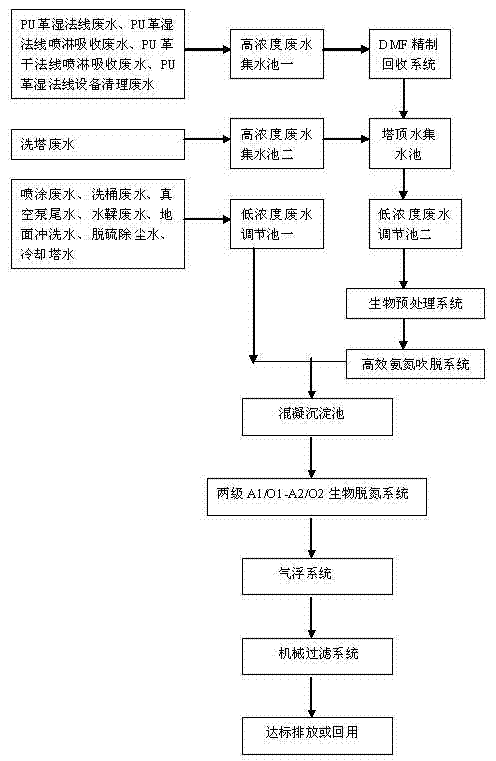

[0030] Such as figure 1 Shown, a kind of PU leather wastewater treatment method of the present invention comprises the following steps:

[0031] Step 1: Classify and dispose of the wastewater in PU leather production

[0032] a. Collect PU leather wet-normal line wastewater, PU leather wet-normal line spray and absorption wastewater, PU leather dry-normal line spray and absorb wastewater, and PU leather wet-normal line equipment cleaning wastewater into high-concentration wastewater collection pool 1. Concentrated wastewater collection tank 1 is built separately or jointly according to the site, and its volume is greater than the maximum discharge of wastewater; the wastewater in high-concentration wastewater collection tank 1 is introduced into the DMF refining recovery system to recover DMF, and the recovered wastewater is collected into the tower top water collection tank , the water sump at the top of the tower is open and naturally cooled;

[0033] b. collecting the tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com