A preparation method of hydrophobic nano-mesoporous molecular sieve filled PDMS composite membrane

A mesoporous molecular sieve, hydrophobic nanotechnology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor swelling resistance and increase physical cross-linking degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

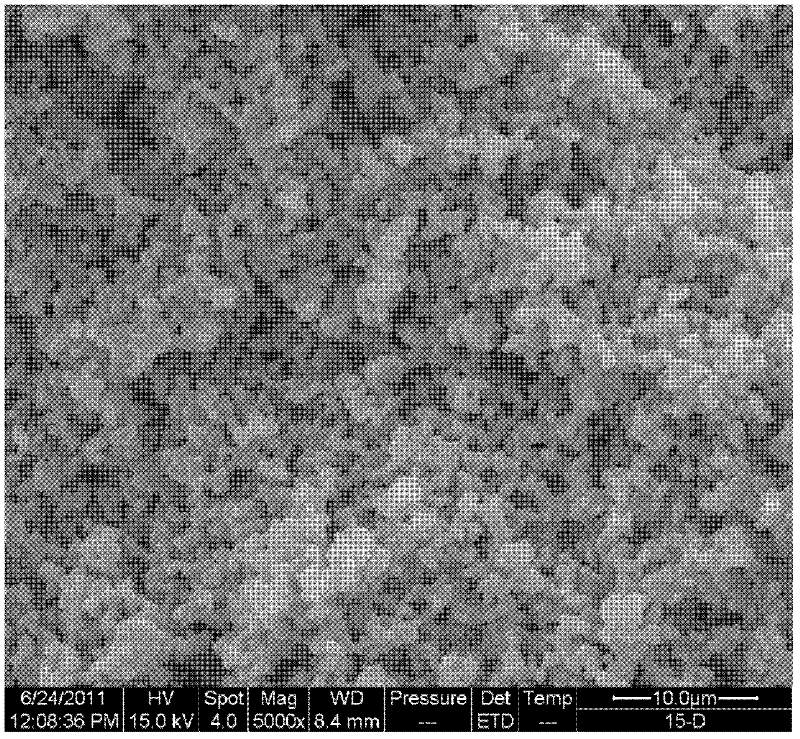

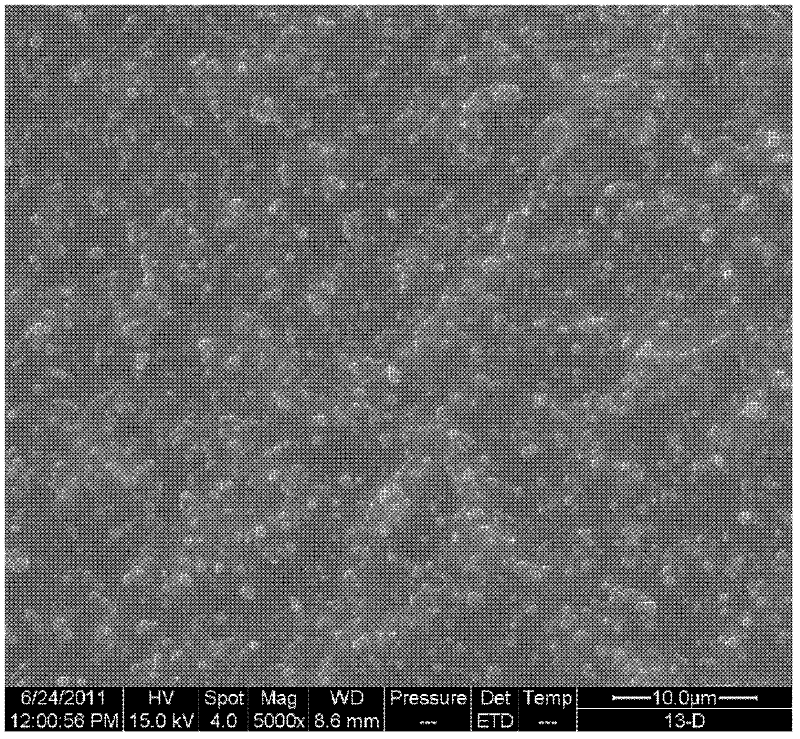

Image

Examples

Embodiment 1

[0030] Dissolve nano-mesoporous molecular sieve MCM-41 in toluene, prepare a solution with a mass concentration of 5%, stir and disperse, add octadecyltrichlorosilane with 50% mass of nano-mesoporous molecular sieve MCM-41, and stir at 50°C for 12h , filtered, washed with toluene, and dried at 300°C to obtain hydrophobic nano-mesoporous molecular sieve MCM-41; 10g RTV615-A, 1.5g RTV615-B were dissolved in 11.2g toluene, and then 5g of the above-mentioned hydrophobic nano-mesoporous molecular sieve was added Pore molecular sieve MCM-41, stir well; scrape the film on the polysulfone (PS) porous bottom film, and dry it in an oven at 80°C for 10 hours to make it completely cross-linked to obtain a composite film. When the concentration of dimethyl carbonate in the feed liquid is 30wt%, the operating temperature is 40°C, and the absolute pressure behind the membrane is 400Pa, the separation factor of the above membrane is 3.88, and the permeation flux is 0.958kg / m 2 h.

Embodiment 2

[0032] Dissolve nanometer mesoporous molecular sieve MCM-48 in n-hexane, prepare a solution with a mass concentration of 15%, stir and disperse, add dropwise octyltrichlorosilane with 10% mass of mesoporous molecular sieve MCM-48, stir at 100°C for 6h, filter After washing with n-hexane and drying at 100°C, hydrophobic nano-mesoporous molecular sieve MCM-48 was obtained; 5g of 107 type PDMS with a viscosity of 50000mpa s, 0.5g of crosslinking agent ethyl orthosilicate, 0.17g of catalyst II Dibutyltin laurate, dissolved in 24.9g of n-hexane, then add 5g of the above-mentioned hydrophobic nano-mesoporous molecular sieve MCM-48, stir evenly; scrape the film on the polyvinylidene fluoride (PVDF) porous bottom film, and keep it in an oven at 100°C Dry it for 8 hours to make it completely cross-linked to obtain a composite membrane. When the concentration of dimethyl carbonate in the feed liquid is 30wt%, the operating temperature is 40°C, and the absolute pressure behind the membra...

Embodiment 3

[0034]Dissolve nano-mesoporous molecular sieve MCM-41 in cyclohexane, prepare a solution with a mass concentration of 30%, stir and disperse, add dodecamethyltrichlorosilane with a mass of nano-mesoporous molecular sieve MCM-41 of 30%, at 70°C Stir for 36 hours, filter, wash with cyclohexane, and dry at 200°C to obtain hydrophobic nano-mesoporous molecular sieve MCM-41; mix 10g of 108-type PDMS with a viscosity of 10000mpa s, 1g of cross-linking agent phenyltrimethoxysilane , 0.33g of catalyst dibutyltin dilaurate, dissolved in 17.75g of n-heptane, then add 0.5g of the above-mentioned hydrophobic nano-mesoporous molecular sieve MCM-41, stir evenly; , and kept in an oven at 120°C for 4 hours to make it completely cross-linked to obtain a composite film. When the concentration of dimethyl carbonate in the feed liquid is 30wt%, the operating temperature is 40°C, and the absolute pressure behind the membrane is 400Pa, the separation factor of the above membrane is 3.38, and the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com