Battery Energy Saving Charging Method

A charging method and storage battery technology, which is applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problems of large grid interference, large investment, and few people use it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

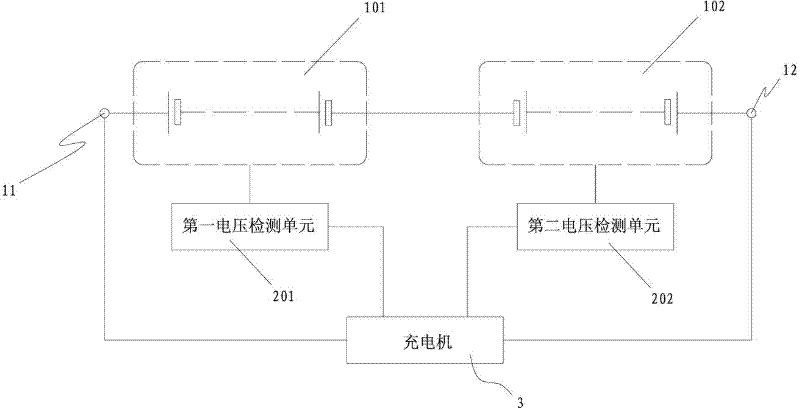

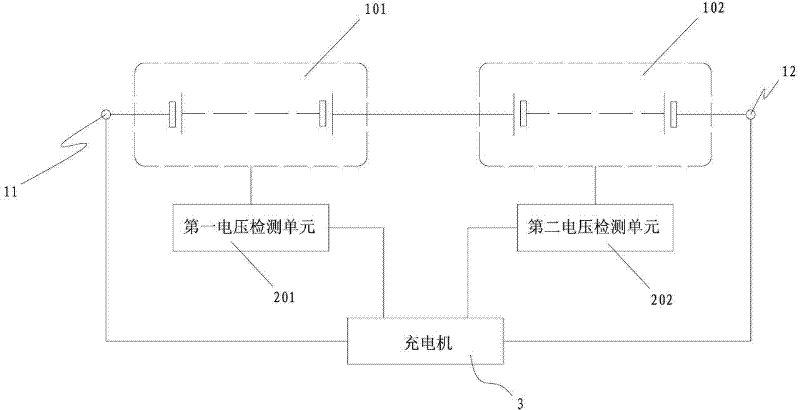

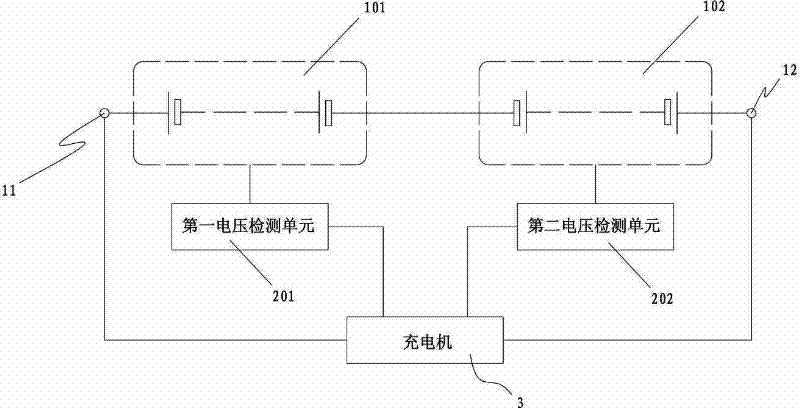

[0021] The main working principle of the present invention is: connect two battery packs in reverse series to form a new battery string, forming a charging form similar to an "hourglass". When the charger charges the battery string, the positive battery pack is charged, and the reverse battery pack is discharged; when the charging flow direction changes, the principle is the same. In this way, it is equivalent to charging another battery pack with the discharged power of one battery pack, and the charger only plays the role of voltage compensation and automatic constant current control functions. After the designed number of cycles is reached, the two sets of battery packs are charged to saturation respectively, and then the two sets of battery packs are properly overcharged to complete the initial charging of the battery packs and complete the stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com