Absorption and Catalytic Decomposition for Ammonia Removal at Low Temperature

A catalytic material, zinc oxide technology, applied in the field of catalysis and environmental science, can solve the problems of limited application and low degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

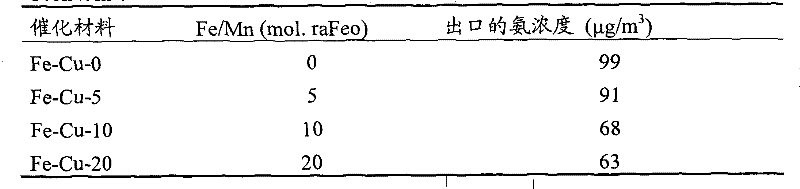

[0022] Copper-iron composite oxide powders are synthesized by soluble copper salts and potassium persulfate (K 2 S 2 o 8 ) mixed with copper sulfate in nitric acid solution, while adding ferric nitrate (Fe(NO 3 ) 2 ), so that the Fe / Cu molar ratio is 0 to 0.20, and the resulting black precipitate is vigorously stirred and refluxed at 100°C for 24h, filtered, washed, dried at 110°C for 12h, and then roasted at 500°C for 6h to obtain a copper-iron composite of iron Oxide powder, respectively marked as Fe-Cu-0, Fe-Cu-5, Fe-Cu-10 and Fe-Cu-20, where Fe-Cu means copper-iron composite oxide, and the number means Fe / Cu total The molar ratio percentage.

[0023] XRD analysis and HRTEM analysis show that the material is copper-iron composite oxide.

[0024] The performance tests of the catalytic materials were carried out in a continuous flow fixed bed reactor. The powdered catalytic material is tableted and crushed to form a 0.25-0.50mm particle sample, and then 0.5g of the part...

Embodiment 2

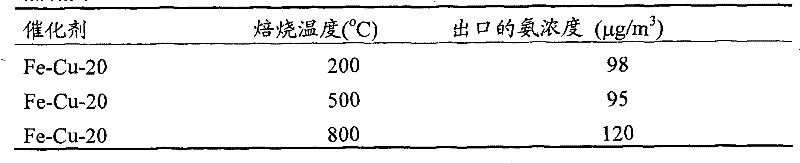

[0026] The synthesis of copper-iron composite oxide powder is with embodiment one, namely by copper salt and potassium persulfate (K 2 S 2 o 8 ) mixed with copper sulfate in nitric acid solution, while adding ferric nitrate (Fe(NO 3 ) 2 ), so that the Fe / Mn molar ratio is 0 to 0.20, the resulting black precipitate is vigorously stirred and refluxed at 100°C for 24h, filtered, washed, dried at 110°C for 12h, and then roasted at 200-800°C for 6h to obtain iron-copper- Iron composite oxide powder, respectively recorded as Fe-Cu-0, Fe-Cu-5, Fe-Cu-10 and Fe-Cu-20, where Fe-Cu represents iron-copper-iron composite oxide, and the number represents Fe / Cu total The molar ratio percentage.

[0027] XRD analysis and HRTEM analysis show that the material is copper-iron composite oxide.

[0028] The performance tests of the catalytic materials were carried out in a continuous flow fixed bed reactor. The powdered catalytic material is tableted and crushed to form a 0.25-0.50mm parti...

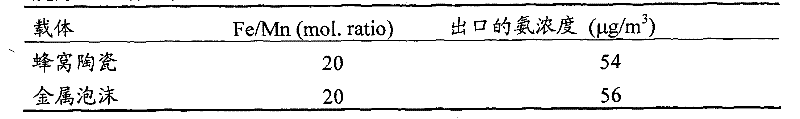

Embodiment 3

[0030] 1) Synthesis of copper-iron composite oxide powder

[0031] The synthesis of copper-iron composite oxide powder is the same as example one, that is, the synthesis of iron-copper-iron composite oxide powder is through copper salt and potassium persulfate (K 2 S 2 o 8 ) mixed with copper sulfate in nitric acid solution, while adding ferric nitrate (Fe(NO 3 ) 2 ), so that the Fe / Cu molar ratio is 0 to 0.20, and the resulting black precipitate is vigorously stirred and refluxed at 100°C for 24h, filtered, washed, dried at 110°C for 12h, and then roasted at 500°C for 6h to obtain a copper-iron composite of iron oxide powder.

[0032] 2) Preparation of catalytic materials supported by copper-iron composite oxide honeycomb ceramics.

[0033] Weigh a certain amount of copper-iron composite oxide, add a certain proportion of deionized water and the inorganic binder in claim 9, and stir at a high speed for 1-24 hours to obtain a copper-iron composite oxide slurry with a cert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com