Large-caliber long-span compensator for conveying pipe

A large-diameter, compensator technology, applied in pipeline expansion compensation devices, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of difficult tank design, long development cycle, fatigue damage, etc. Avoid the modification of tank structure, avoid fatigue damage, reduce the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

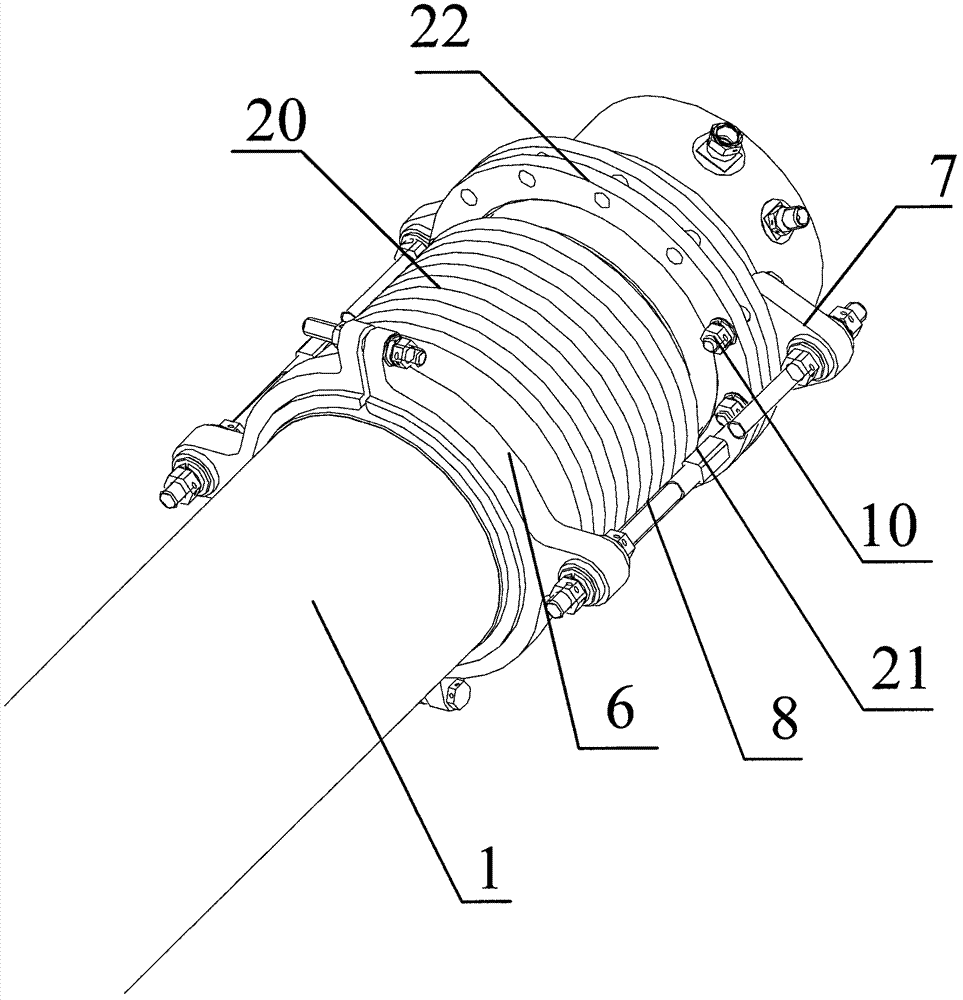

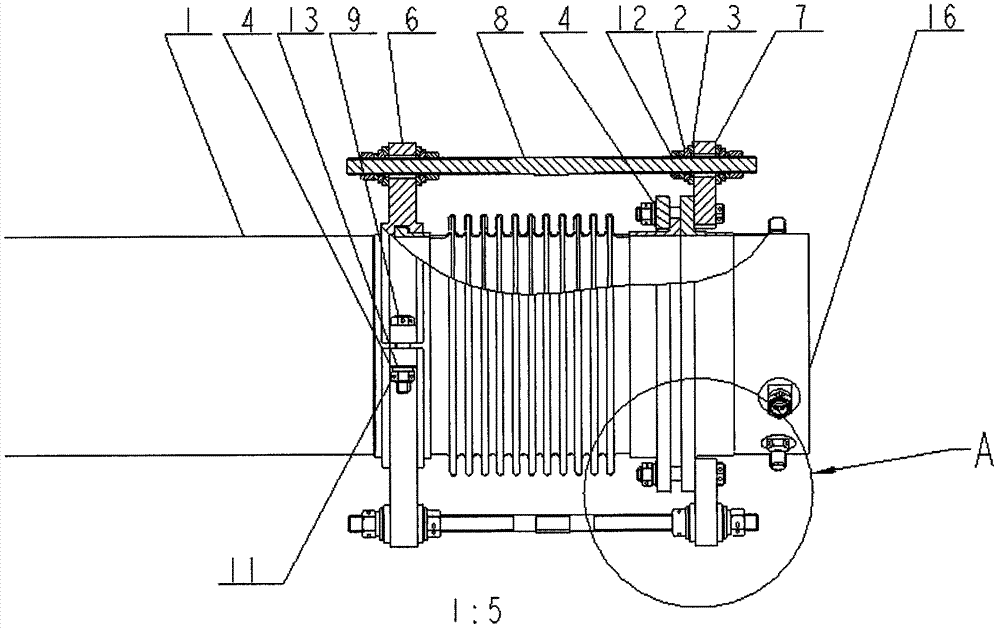

[0037] The axial length of the booster oxygen delivery pipe is about 5800 mm, and the radial length is about 470 mm. There is a bellows 20 at the front and back of the delivery pipe 1, such as figure 1 Shown is the structural outline drawing of the compensator for the delivery pipe of the present invention, wherein the compensator is a symmetrically distributed pull rod limiting device on the bellows 20, such as figure 1 As shown, the pull rod limiting device includes a block 6 , a spacer 7 and a pull rod 8 .

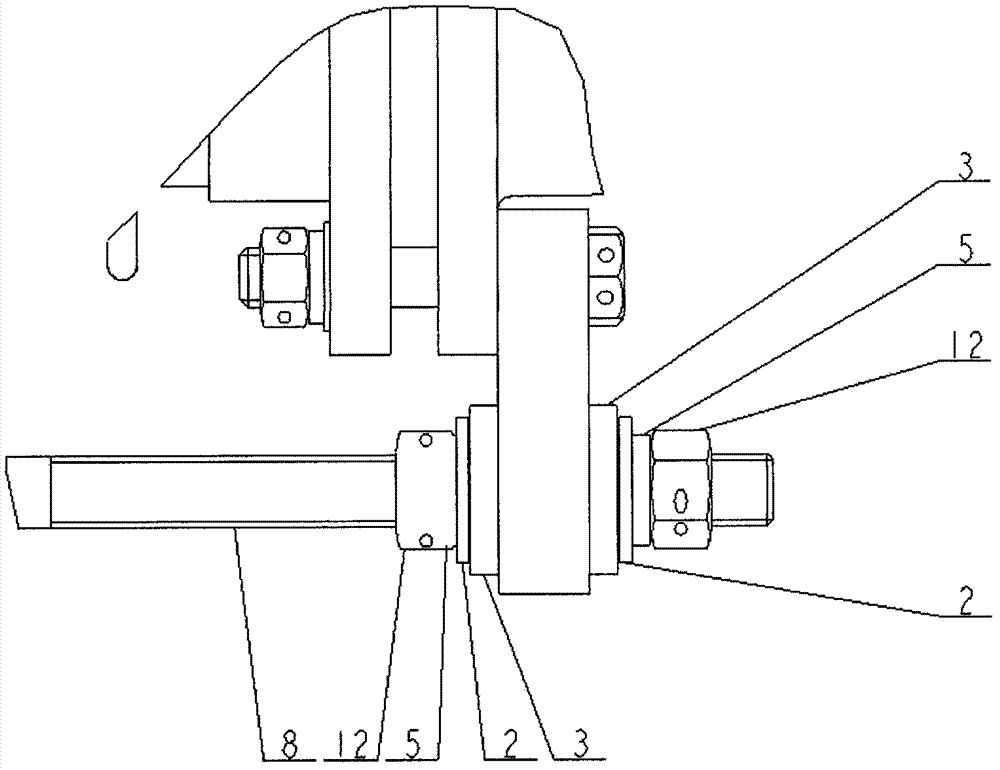

[0038] like Image 6 Shown is a schematic diagram of the block structure in the compensator for the delivery pipe of the present invention, Figure 7 It is a sectional view of the clamping block structure in the compensator for delivery pipes of the present invention, the clamping block 6 is a semicircular structure with a groove 30, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com