A kind of fluorine-containing cationic imidazoline corrosion inhibitor and preparation method thereof

A technology of imidazoline corrosion inhibitors and cations, which is applied in the field of fluorine-containing cation imidazoline corrosion inhibitors and its preparation, can solve problems such as the adverse effects of corrosion inhibition rate and the influence of popularization and application of imidazoline corrosion inhibitors, and achieve good mitigation Erosion rate, not easy to fall off, and the effect of reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

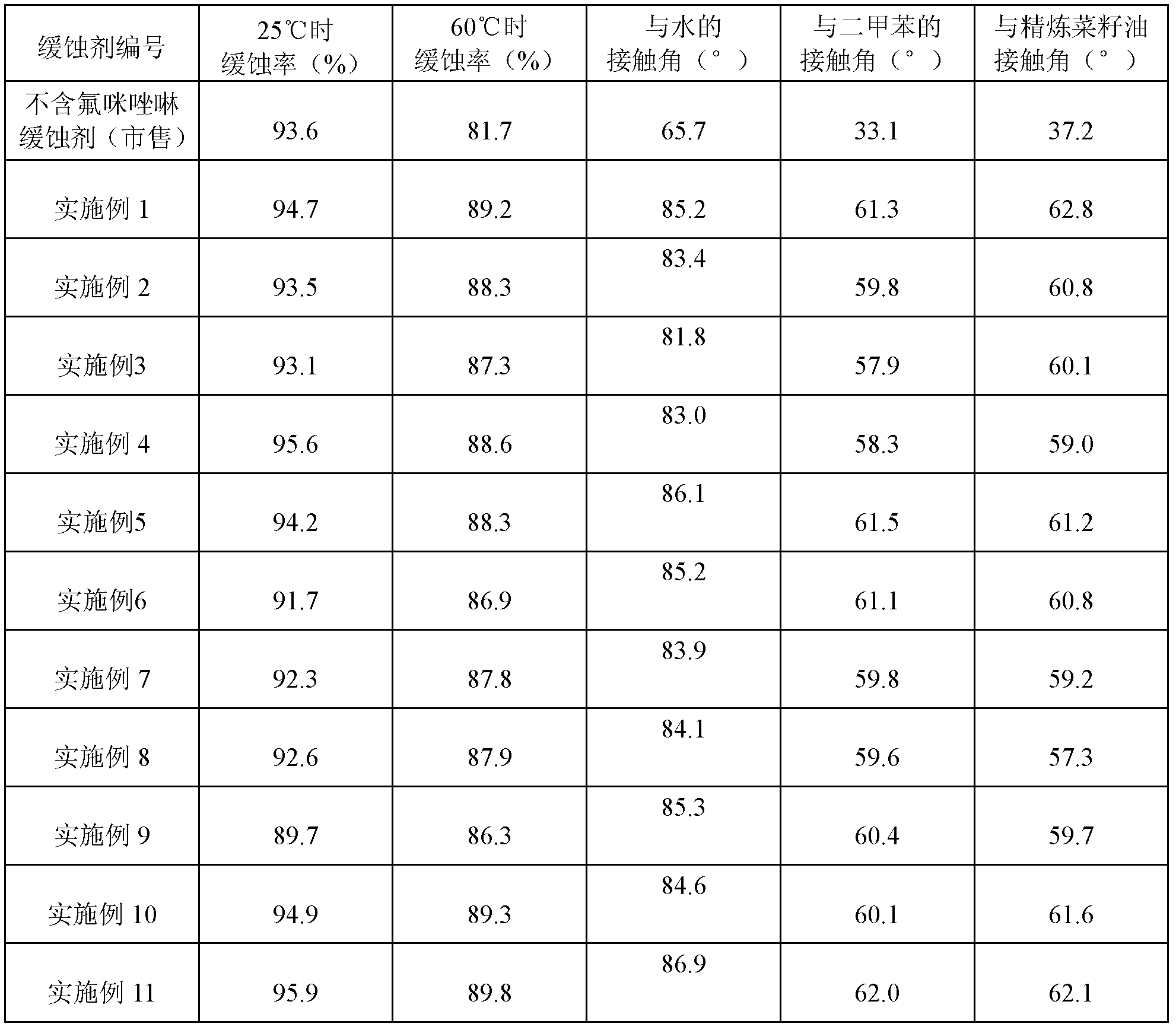

Examples

Embodiment 1

[0020] Organic carboxylic acid and diethylene triamine are added into the reactor according to the molar ratio of 1:0.1 to obtain the reactant, and the organic carboxylic acid is saturated or unsaturated C 1 -C 22 Monohydric aliphatic organic carboxylic acids, the saturated or unsaturated C 1 -C 22 The monobasic aliphatic organic carboxylic acid is oleic acid, and benzene solvent is added in the reactant, and the mass ratio of reactant and benzene solvent is 1: 0.1, and described benzene solvent is xylene, after adding benzene solvent, heat and React at 130°C for 0.5h, then heat up and perform cyclization reaction at 190°C for 0.5h, cool to 80°C after the cyclization reaction, add perfluoroalkylsulfonyl fluoride, perfluoroalkylsulfonyl fluoride and organic carboxylic acid dropwise after cooling The molar ratio is 1:0.1, the perfluoroalkyl sulfonyl fluoride is perfluorobutyl sulfonyl fluoride, after the perfluoroalkyl sulfonyl fluoride is added dropwise, the reaction is kept ...

Embodiment 2

[0022] Add organic carboxylic acid and diethylenetriamine into the reactor according to the molar ratio of 1:2 to obtain the reactant, the organic carboxylic acid is saturated or unsaturated C 1 -C 22 Monohydric aliphatic organic carboxylic acids, the saturated or unsaturated C 1 -C 22 Monohydric aliphatic organic carboxylic acid is stearic acid, add benzene solvent in reactant, the mass ratio of reactant and benzene solvent is 1: 2, described benzene solvent is m-xylene, heat after adding benzene solvent And react at 165°C for 5h, then heat up and perform cyclization reaction at 210°C for 5h, cool to 110°C after the cyclization reaction, drop perfluoroalkylsulfonyl fluoride, perfluoroalkylsulfonyl fluoride and organic carboxylic acid The molar ratio is 1:2, the perfluoroalkyl sulfonyl fluoride is perfluorohexyl sulfonyl fluoride, the perfluoroalkyl sulfonyl fluoride is added dropwise and then incubated for 5 hours, and the quaternizing reagent, quaternary ammonium The mola...

Embodiment 3

[0024] Add organic carboxylic acid and diethylenetriamine into the reactor according to the molar ratio of 1:0.4 to obtain the reactant, the organic carboxylic acid is saturated or unsaturated C 1 -C 22 Monohydric aliphatic organic carboxylic acids, the saturated or unsaturated C 1 -C 22 The monobasic aliphatic organic carboxylic acid is coconut oil acid, add benzene solvent in the reactant, the mass ratio of reactant and benzene solvent is 1: 0.4, and described benzene solvent is p-xylene, heat after adding benzene solvent And react at 140°C for 1.5h, then raise the temperature and perform cyclization reaction at 195°C for 1.5h, cool to 85°C after the cyclization reaction, add perfluoroalkylsulfonyl fluoride dropwise after cooling, perfluoroalkylsulfonyl fluoride and organic The molar ratio of the carboxylic acid is 1:0.4, the perfluoroalkylsulfonyl fluoride is perfluorooctanesulfonyl fluoride, after the perfluoroalkylsulfonyl fluoride is added dropwise, the reaction is kep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com