Fixed bed pipe type reaction device for realizing solid acid catalytic hydrolysis and concentration of liquid glycan

A tubular reaction device and a technology of solid acid catalysis, which are applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of increased energy consumption, increased production costs, and increased nutrients in the ethanol refining process, and are easy to operate and The effect of maintenance, reduction of reaction energy consumption, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

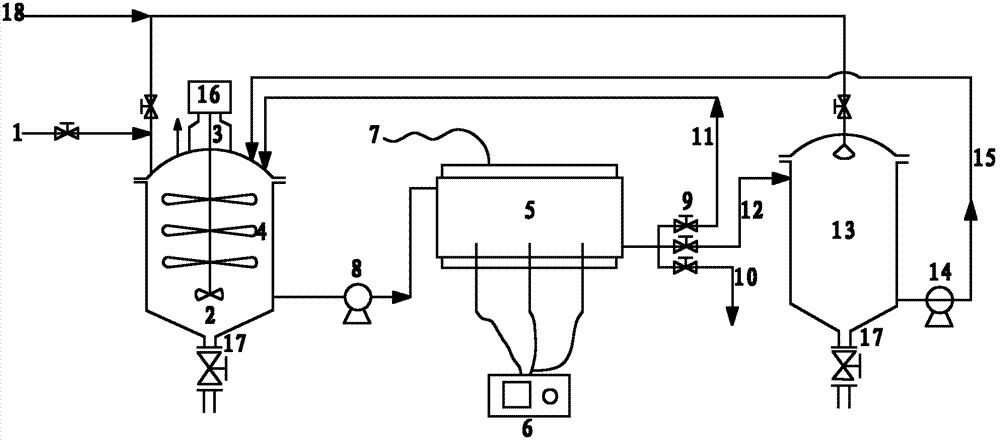

[0033] to combine figure 1, taking the single injection reaction of the polysaccharide solution generated after the pretreatment of the biomass raw material (corn stalk) as an example, the operation method of the system in the present invention is described:

[0034] (1) Open the valve at the raw material input pipe 1, so that the pretreated polysaccharide solution enters the raw material storage tank 2, and open the stirring shaft 3 in the stirring system, and the stirring shaft 3 drives the stirring paddle 4 to the polysaccharide raw material liquid to stir;

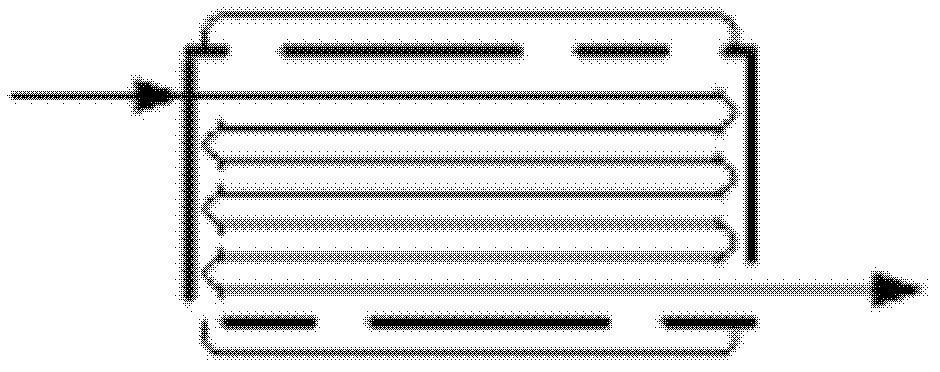

[0035] (2) Turn on the temperature display of the fixed-bed tubular reactor 5 and the switch of the control instrument 6 and the electric furnace wire 7, and set the temperature slightly higher than the required reaction temperature;

[0036] (3) After the temperature displayed by the temperature display and control instrument 6 reaches the set temperature, turn on the first high-pressure metering pump 8 to transport ...

Embodiment 2

[0044] combine figure 1 , taking the continuous sampling reaction of the polysaccharide solution generated after the pretreatment of the biomass raw material (corn stalk) as an example, the operating method of the system in the present invention is described:

[0045] (1)-(5) are identical with embodiment 1;

[0046] (6) After the reaction is completed, close the discharge pipe 10, adjust the flow of the return pipe 11 and the liquid sugar delivery pipe 12, and realize the shunting of the liquid material, so that a part of the material returns to the raw material storage tank 2, and another part of the material enters the sugar liquid In storage tank 13;

[0047] (7) After the shunting is completed, open the second high-pressure metering pump 14 connected to the bottom of the sugar liquid storage tank 13, adjust the flow rate, and make a part of the sugar liquid flow back to the raw material storage tank 2 through the reflux concentration pipe 15, according to the needs of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com