A method for pyrolyzing coal using a regenerative rotary furnace

A rotary furnace, regenerative technology, used in coke ovens, special forms of dry distillation, petroleum industry and other directions, can solve the problems of difficult removal, complex treatment process, low single furnace output, etc., to achieve short process, high efficiency and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

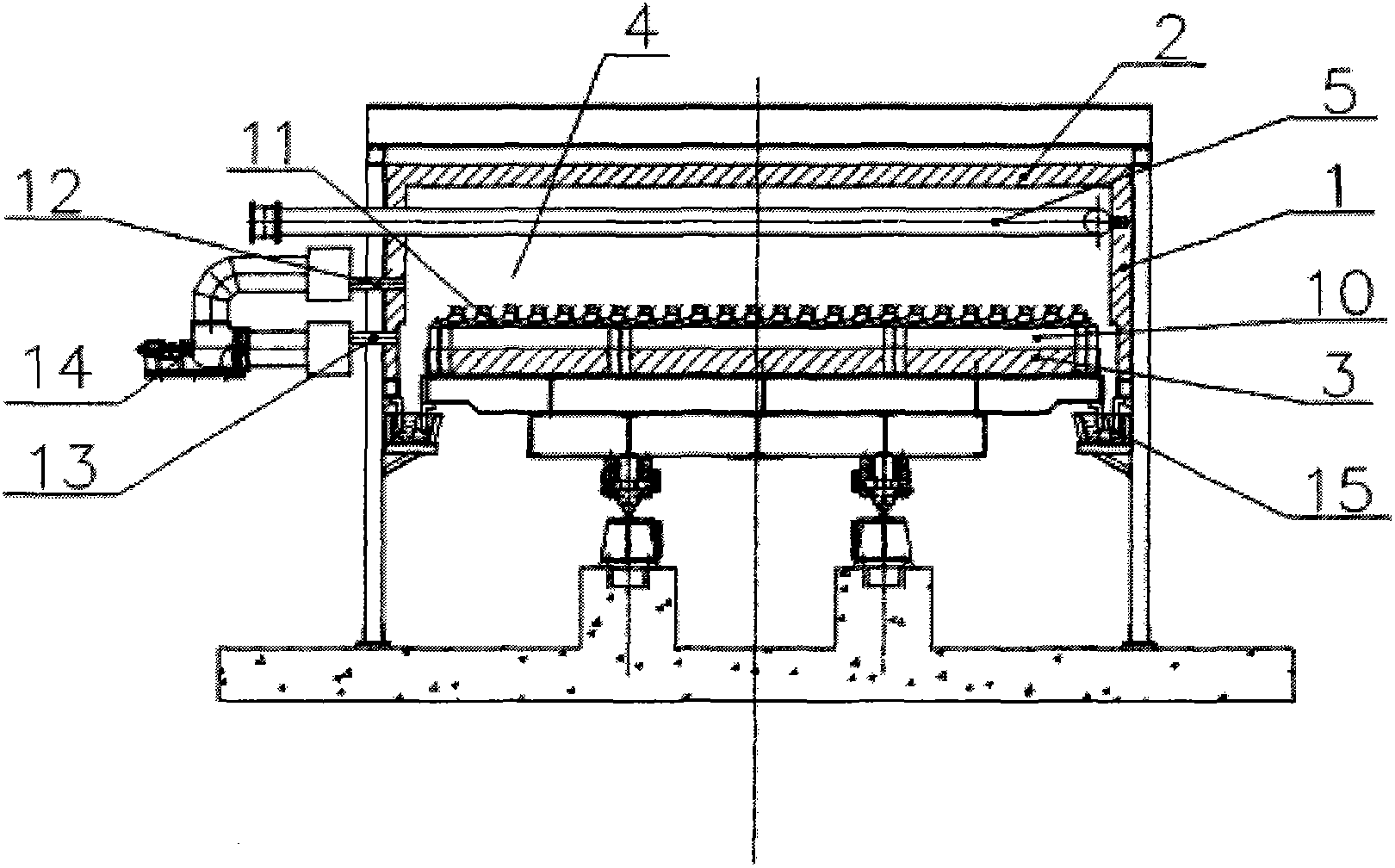

[0030] The regenerative rotary furnace structure described in embodiment 1

[0031] Such as figure 1 As shown, the regenerative rotary furnace includes a furnace wall 1, a furnace roof 2 and a furnace bottom 3, and the furnace wall, furnace roof and furnace bottom form a furnace 4; the furnace bottom is a rotary furnace bottom, Horizontal rotation in the furnace; the upper space of the furnace is provided with one or more regenerative radiant tubes 5 .

[0032] Such as figure 1 As shown, the regenerative radiant tube is a straight tube.

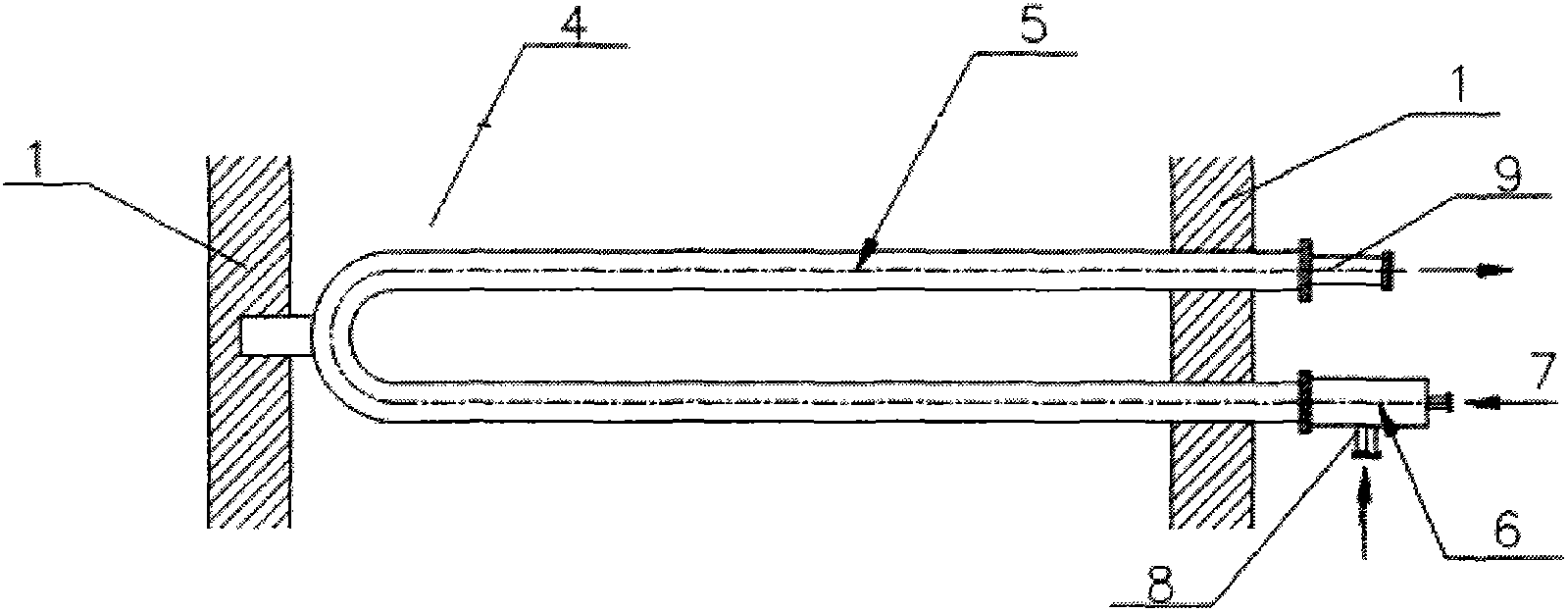

[0033] or, as in figure 2 As shown, the regenerative radiant tube is a U-shaped tube.

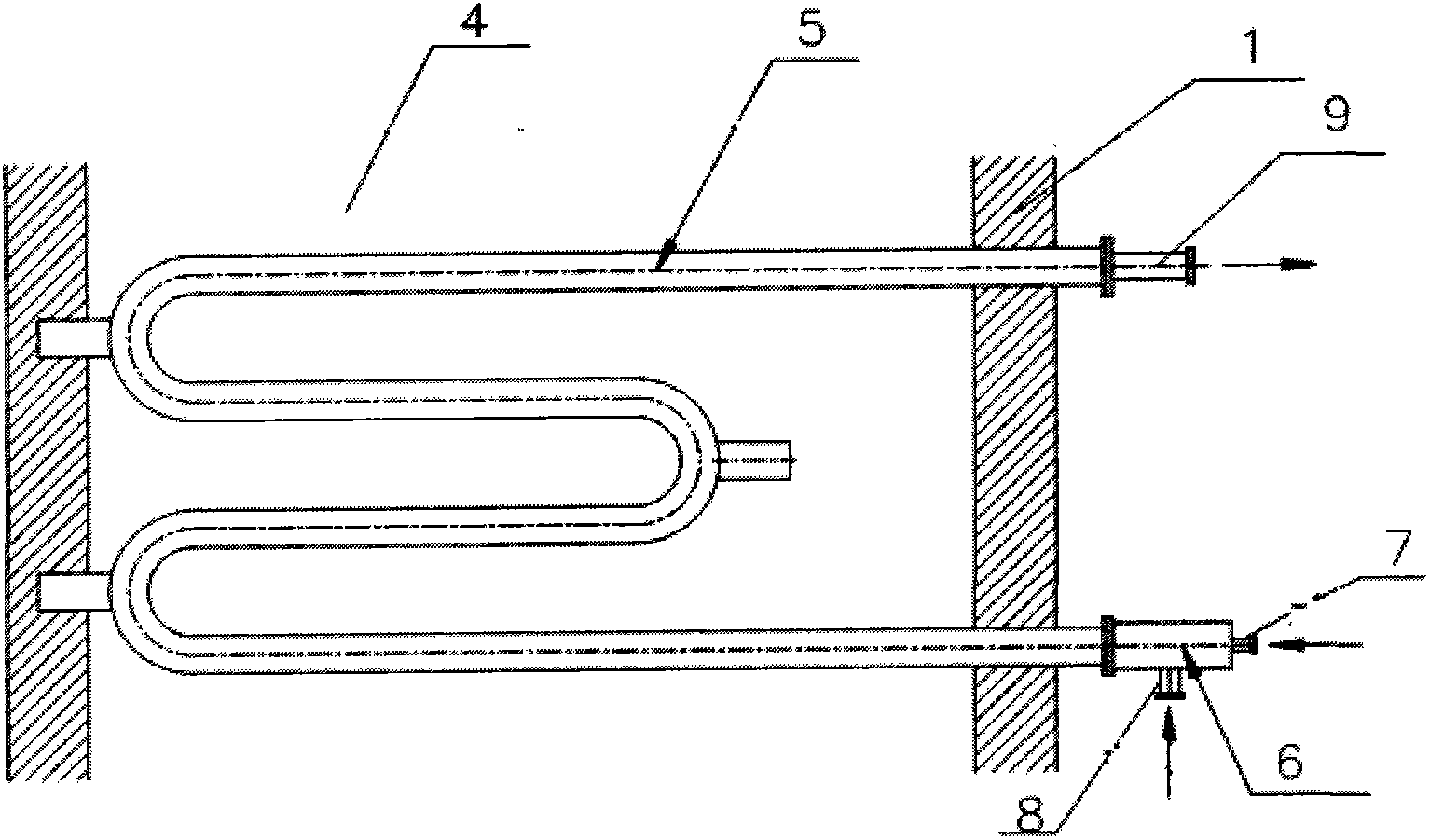

[0034] or, as in image 3 As shown, the regenerative radiant tube is a W-shaped tube.

[0035] Such as figure 2 with image 3 As shown, one end of the regenerative radiant tube is provided with a burner 6 , the burner is provided with a gas inlet 7 and an air inlet 8 , and the other end of the regenerative radiant tube is a flue gas outlet 9 .

...

Embodiment 2

[0039] Embodiment 2 Utilizes the method for thermally decomposing coal in a regenerative rotary furnace

[0040] The method comprises the steps of:

[0041] 1), crushing and drying: crushing, screening and drying the raw materials to be pyrolyzed;

[0042] The crushing particle size is 10-100 mm; raw materials larger than 100 mm are further crushed and sieved, and raw materials smaller than 10 mm are pressed into pellets.

[0043] 2) Cloth pyrolysis: Distribute the crushed and dried raw materials on the bottom of the regenerative rotary furnace through the distributing device, heat to 400°C-700°C, keep for 30-120 minutes, and the raw materials are pyrolyzed Generate semi-coke and dry distillation gas;

[0044] 3) Discharge: semi-coke is discharged through the discharge device, and semi-coke at 400°C-700°C is quenched and sent to the finished product yard; the dry distillation gas is separated from oil and gas to obtain product tar and raw gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com