Preparation method of nanocomposite epoxy polysiloxane coating cured at room temperature and coating thereof

A technology of epoxy polysiloxane and nanocomposite, which is applied in epoxy resin coatings, coatings, and devices for coating liquid on the surface, etc., which can solve the problems of UV aging resistance, easy cracking, and low corrosion resistance, and achieve The manufacturing process is simple, the cost is low, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

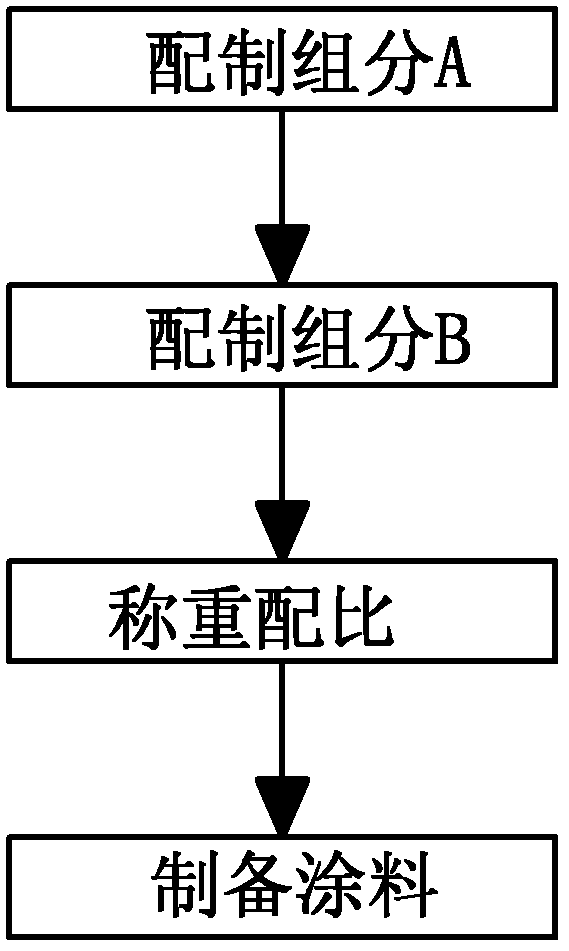

[0068] First example: see figure 1 , the present embodiment provides a method for preparing a nanocomposite epoxy polysiloxane coating cured at room temperature, which comprises the following steps:

[0069] (1) Preparation of component A: the components of component A and their weight percentages are as follows:

[0070] Epoxy resin 10-60%,

[0071] Polysiloxane resin 10-70%,

[0072] Titanium dioxide 5-30%,

[0074] Nano material 1~10%,

[0075] Auxiliary 0.1~2%,

[0076] Organic solvent 1~15%;

[0077] Described step (1), it specifically comprises the following steps: (1.1) the auxiliary agent of corresponding formula quantity and 90% organic solvent of corresponding formula quantity are mixed in advance to prepare solution, then the epoxy resin of corresponding formula quantity and The polysiloxane resin of the corresponding formula quantity is dissolved in the solution, and then put into the high-speed disperser to achieve uniform mixing...

no. 2 example

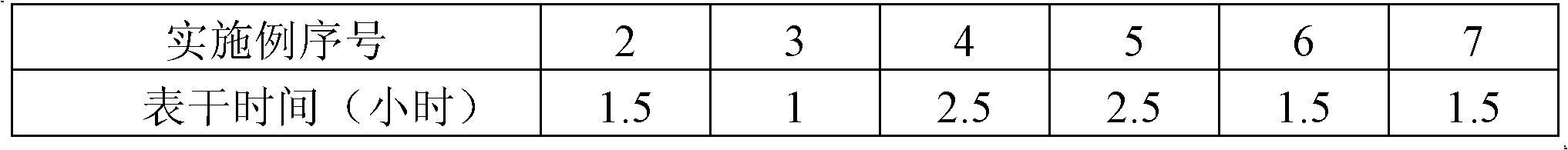

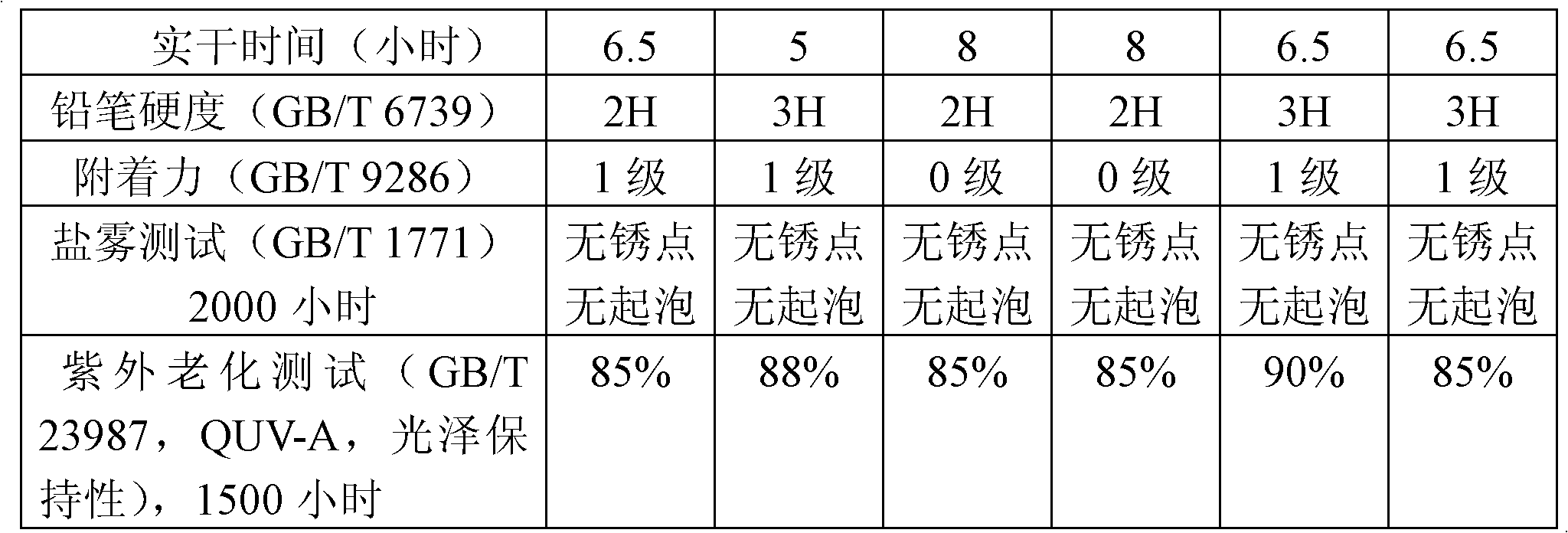

[0111] The second embodiment is a coating of the above room temperature curing nanocomposite epoxy polysiloxane coating preparation method, the coating is composed of component A and component B. Wherein the components of component A and their weight percentages are as follows: 20% aliphatic epoxy resin, 40% alkoxy functional polysiloxane resin, 10% titanium dioxide, 10% talcum powder, nano SiO 2 4%, dispersant 1.0%, defoamer 0.5%, leveling agent 0.5%, xylene 5%, ethyl acetate 9%. The components of component B and their weight percentages are as follows: 90% of aminosilane, 5% of butyl acetate, and 5% of dibutyltin dilaurate. The weight ratio of component A and component B is 10:3.5.

no. 3 example

[0112] The third embodiment differs from the second embodiment in that the component ratios and weight ratios of component A and component B are different. The paint consists of component A and component B. Wherein the components of component A and their weight percentages are as follows: 25% aliphatic epoxy resin, 50% alkoxy functional polysiloxane resin, 6% titanium dioxide, 2% talcum powder, nano TiO 2 6%, dispersant 1.0%, defoamer 0.5%, leveling agent 0.5%, ethyl acetate 9%. The components of component B and their weight percentages are as follows: 90% of aminosilane, 5% of butyl acetate, and 5% of dibutyltin dilaurate. The weight ratio of component A and component B is 10:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com