A kind of preparation method of synthetic cobalt-gold bimetallic alloy nanoparticles

A technology for synthesizing cobalt-gold alloy nanoparticles and cobalt-gold, which is applied in the field of preparation of cobalt-gold bimetallic alloy nanoparticles, which can solve problems affecting material performance and application, single product structure, poor component adjustability, etc., and achieve low reaction toxicity , simple process and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

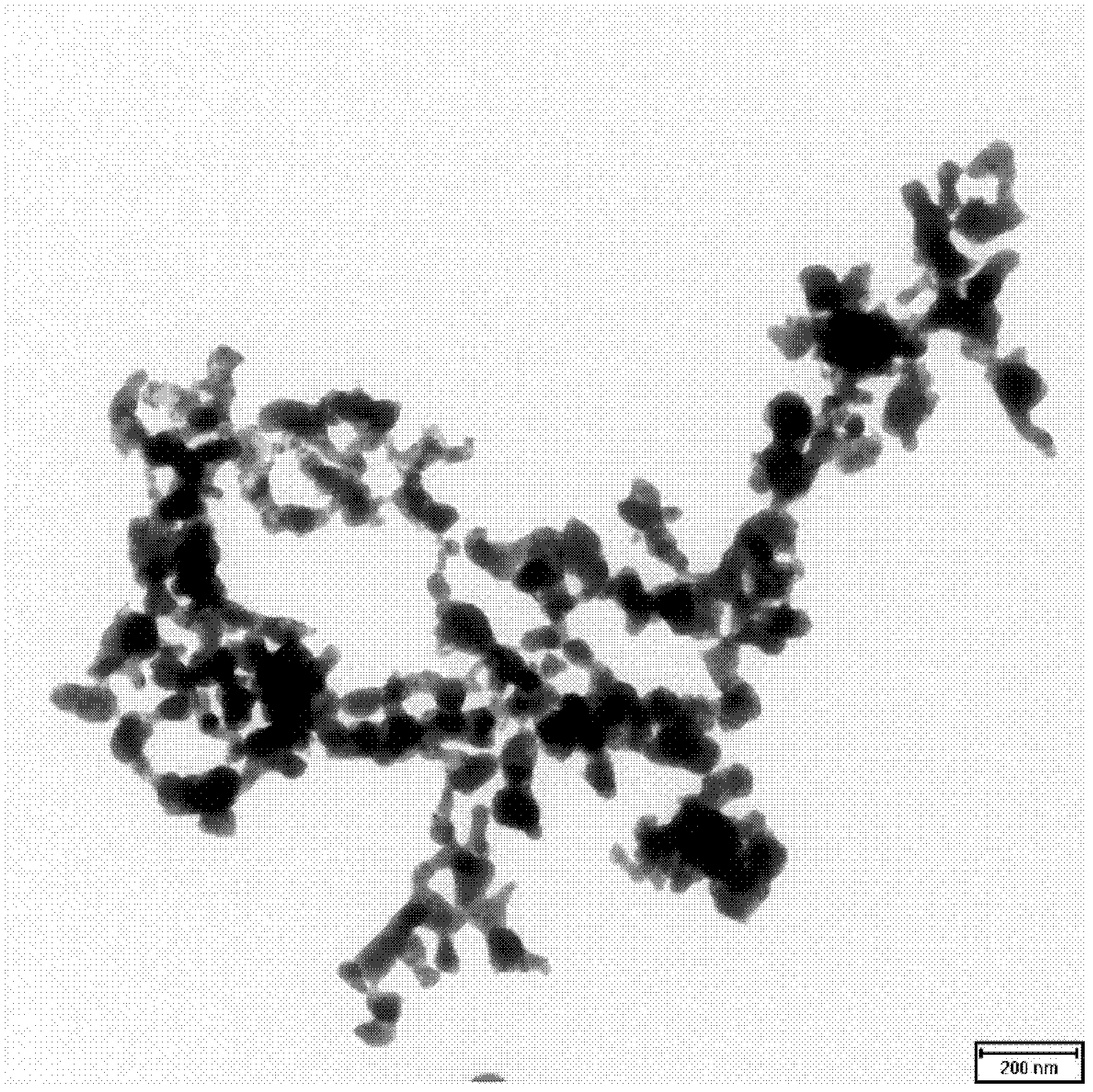

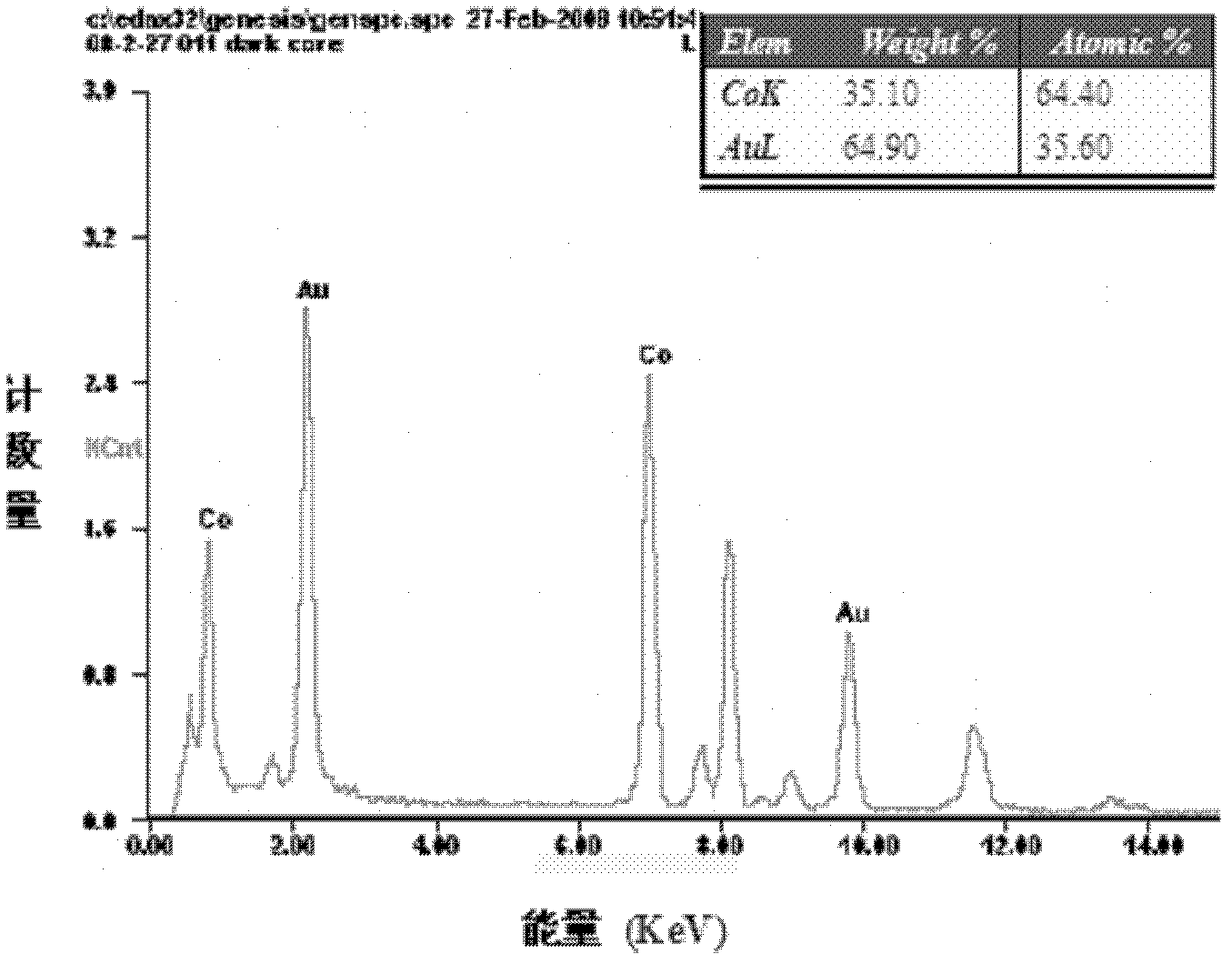

[0021] The preparation method of a kind of synthetic cobalt-gold bimetallic alloy nano-particle that the present invention proposes adopts chemical solution method, such as figure 1 As shown, it specifically includes the following steps:

[0022] Step 1: Add polyvinylpyrrolidone (PVP) and inorganic salt of cobalt to ethylene glycol solvent (purity greater than 98%), the molar ratio of polyvinylpyrrolidone (PVP) and inorganic salt of cobalt is 0.5: 1~3: 1 , the molar concentration of cobalt ions is 0.01-0.05 mol / L to obtain a mixed solution. The inorganic salt of cobalt is selected from any one of cobalt chloride, cobalt acetate and cobalt nitrate.

[0023] Step 2: Add 1.5 to 3.0 mL of hydration well (mass fraction greater than or equal to 50%) to the mixture under stirring conditions, and after stirring evenly, a pink turbid solution is obtained, and further add substances to it under stirring conditions The concentration is 1×10 -4 ~1×10 -2 mol / L (preferably 5×10 -3 mol / ...

Embodiment 1

[0027] A preparation method for synthesizing cobalt-gold bimetallic alloy nanoparticles proposed in this embodiment specifically includes the following steps:

[0028] Step 1: Add 0.011g polyvinylpyrrolidone (PVP) and 0.018g cobalt acetate to 10mL ethylene glycol solvent (purity greater than 98%), the mol ratio of polyvinylpyrrolidone (PVP) and cobalt acetate is 1: 1, cobalt ion The molar concentration was 0.01 mol / L, and a mixed solution was obtained.

[0029] Step 2: under stirring condition, add 1.5mL hydration well (mass fraction equals 50%) to mixed solution, after stirring evenly, obtain pink turbid solution, continue to wherein further add 20mL chloroauric acid ethyl alcohol under stirring condition Glycol solution (5×10 -3 mol / L), keep the molar ratio of cobalt ions and gold ions in the solution at 1:1, the solution turns from pink to blue-purple, heat with an electric heating mantle, and react for 2 hours at a reaction temperature of 195° C., the solution A black pr...

Embodiment 2

[0033] A preparation method for synthesizing cobalt-gold bimetallic alloy nanoparticles proposed in the embodiment of the present invention specifically includes the following steps:

[0034] Step 1: To 20mL ethylene glycol solution (purity is greater than 98%), then add 0.33g polyvinylpyrrolidone (PVP) 0.239g cobalt chloride hexahydrate therein, the mol ratio of the inorganic salt of polyvinylpyrrolidone (PVP) and cobalt The ratio is 3:1, the molar concentration of cobalt ions is 0.05mol / L, and a mixed solution is obtained.

[0035] Step 2: Add 1.5 to 3.0 mL of hydration trap (mass fraction greater than or equal to 50%) to the mixture under stirring conditions, and after stirring evenly, a pink turbid solution is obtained, and further add 20 mL of chlorine to the mixture under stirring conditions Ethylene glycol solution of gold acid (5×10 -3 mol / L), keep the molar ratio of cobalt ions and gold ions in the solution at 10:1, and react for 2 hours at a reaction temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com