A kind of beneficiation method of purifying bastnaesite concentrate

A beneficiation method, bastnaesite technology, applied in flotation, solid separation, etc., can solve the problems of three wastes pollution, failure to achieve high recovery rate, poor separation effect, etc., achieve high recovery rate and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

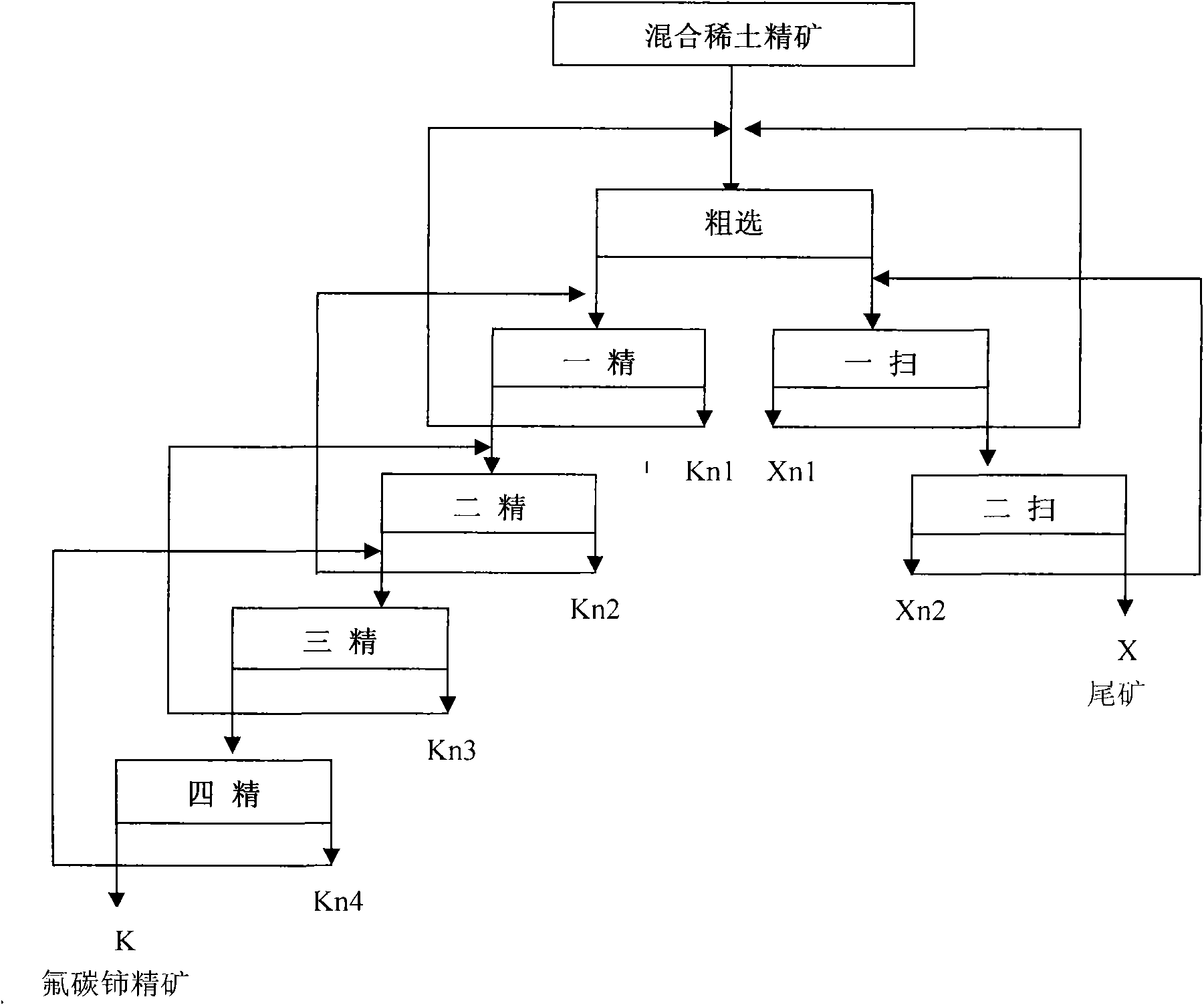

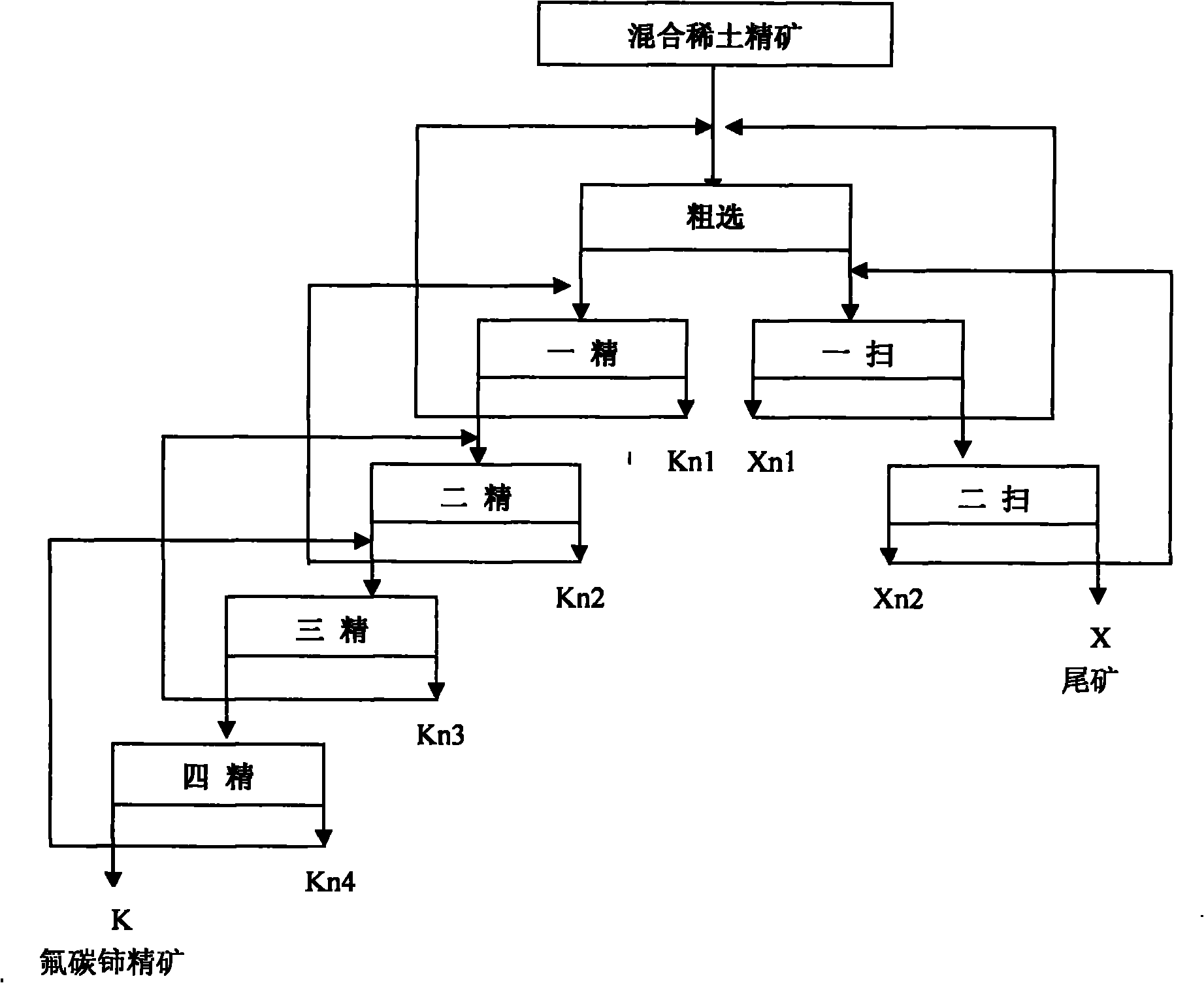

[0029] Bastnaesite concentrate is separated from a mixed rare earth concentrate by flotation. The REO content in the mixed rare earth concentrate is 50.5%, the bastnaesite REO is 30.7%, and the bastnaesite purity is 60.8%. Bastnaesite concentrate is separated and prepared from this mixed mineral by using a closed-circuit cycle mineral processing process of beneficiation, four times of beneficiation, and two times of sweeping. Specific steps are as follows:

[0030] (1) Rough separation: put bastnaesite-based mixed rare earth concentrate into the flotation tank, add water to mix and adjust the slurry, the mass concentration of the slurry is 30%, stir, and add 3.5kg of alum in turn by weight / t, phthalic acid 3.5kg / t, No. 2 oil 0.015kg / t, pulp temperature 18°C, pulp pH 4.0, rough separation to obtain rough separation bastnaesite concentrate and rough separation tailings;

[0031](2) Concentration: Add the coarsely selected bastnaesite concentrate to the flotation tank, add wate...

Embodiment 2

[0035] Bastnaesite concentrate is separated from a mixed rare earth concentrate by flotation. The REO content in the mixed rare earth concentrate is 41.5%, the bastnaesite REO is 33.4%, and the bastnaesite purity is 84.9%. Bastnaesite concentrate is separated and prepared from this mixed mineral by using a closed-circuit cycle mineral processing process of beneficiation, four times of beneficiation, and two times of sweeping. The reagent system during flotation is: rough selection: alum 2.7kg / t, phthalic acid 2.5kg / t, No. 2 oil 0.015kg / t; 2.0kg / t, No. 2 oil 0.010kg / t; Second essence: alum 1.5kg / t, phthalic acid 2.0kg / t, No. 2 oil 0.010kg / t; Three essence: alum 1.2kg / t, phthalate Diformic acid 1.5kg / t, No. 2 oil 0.005kg / t; Four essences: alum 1.0kg / t, phthalic acid 1.5kg / t, No. 2 oil 0.010kg / t; sweep: alum 1.5kg / t , phthalic acid: 2.0kg / t, No. 2 oil 0.015kg / t; second cleaning: alum 1.3kg / t, phthalic acid: 1.8kg / t, No. 2 oil 0kg / t; mass concentration of roughing pulp Control a...

Embodiment 3

[0038] Flotation separation of bastnaesite concentrate from a mixed rare earth concentrate, the content of REO in the mixed rare earth concentrate is 55.2%, the REO of bastnaesite is 41.9%, and the purity of bastnaesite is 75.9%. Bastnaesite concentrate is separated and prepared from this mixed mineral by using a closed-circuit cycle mineral processing process of beneficiation, four times of beneficiation, and two times of sweeping. The reagent system during flotation is: rough selection: alum 5.5kg / t, phthalic acid 4.5kg / t, No. 2 oil 0.020kg / t; t, No. 2 oil 0.010kg / t; Second essence: alum 2.5kg / t, phthalic acid 3.0kg / t, No. 2 oil 0.010kg / t; Three essence: alum 1.5kg / t, phthalic acid 2.0 kg / t, No. 2 oil 0.010kg / t; four essences: alum 1.0kg / t, phthalic acid 1.5kg / t, No. 2 oil 0.010kg / t; sweep: alum 1.5kg / t, phthalate Formic acid 1.5kg / t, No. 2 oil 0.015kg / t; Second cleaning: alum 1.5kg / t, phthalic acid 2.0kg / t, No. 2 oil 0.015kg / t; the mass concentration of roughing pulp is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com