A method for producing an integral volute supercharged exhaust manifold

A technology for exhaust manifolds and production methods, which is applied in the field of auto parts and can solve the problems of light weight, large volume, and rough flow paths that do not meet the requirements of automobiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

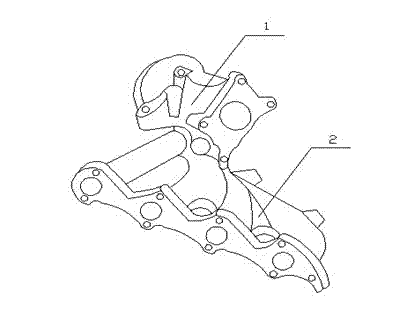

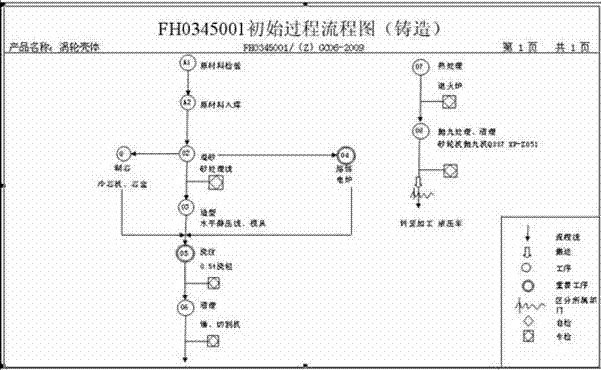

[0028] like figure 1 , figure 2 , image 3 Shown, below by specific embodiment, further illustrate advantage of the present invention:

[0029] An integral volute supercharged exhaust manifold includes a turbocharger turbine shell 1 and an exhaust manifold 2, and the turbocharger turbine shell 1 and the exhaust manifold 2 are integrally cast and processed.

[0030] The austenitic ductile iron QTANi35Si5Cr2 contains the following chemical composition (unit, wt%) in mass percentage: C: ≤2.0%; Si: 4-6%; Mn: 0.5-1.5%; Ni: 34.0-36% ; Cr: 1.5~2.5%; Cu≤0.5%; P≤0.05%; S≤0.03%.

[0031] The production method of described austenitic nodular cast iron QTANi35Si5Cr2 comprises the steps:

[0032] a. Storage control of raw and auxiliary materials: for purchased high-quality pig iron (Q10, Q12 produced in Linzhou), high-quality low-carbon steel scrap, nickel-magnesium nodulizers, silicon-magnesium alloy nodulizers, silicon-strontium inoculants, and 75SiFe inoculants Carry out factory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com