Vacuum potassium carbonate method for utilizing coke oven coal gas desulphurization and decyanation waste liquid as resource

A vacuum potassium carbonate, desulfurization and decyanation technology, applied in the field of waste recycling and treatment, can solve the problems of frequent replacement of iron electrodes, difficulty in precipitation of sulfide and cyanide, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

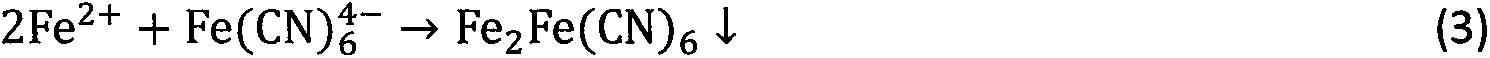

Method used

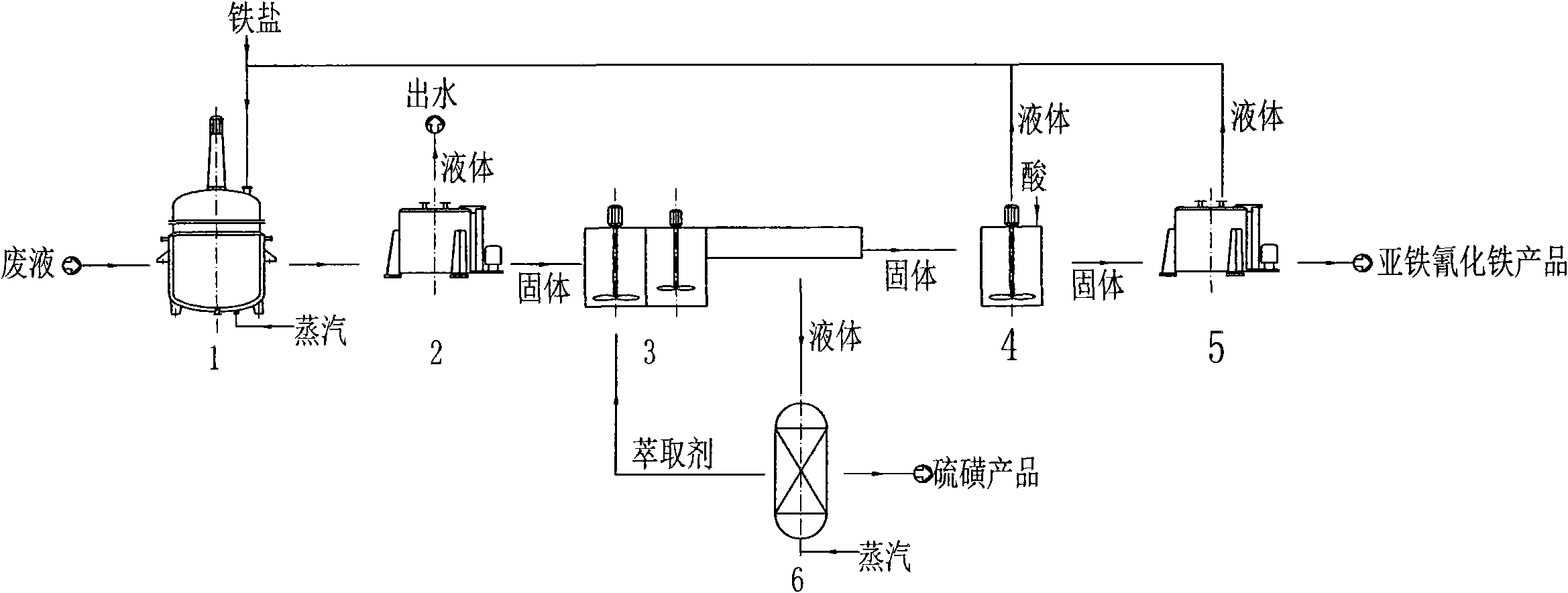

Image

Examples

Embodiment 1

[0028] Embodiment 1: small test of vacuum potassium carbonate method desulfurization and decyanation waste liquid treatment, each batch processing capacity is 1L, the total cyanide concentration of the original waste liquid is 14853mg / L, S 2-It is 4519mg / L. After adding ferrous sulfate, the temperature is 50°C, the pH is 6, and the cyanide in the effluent is about 738mg / L, S 2- It is less than 25mg / L, and the removal rate is greater than 95%. Add NaOH after precipitation and filtration, react at 90°C to form yellow blood salt, crystallize at 15°C, and recover about 26g of yellow blood salt per liter of wastewater.

Embodiment 2

[0029] Embodiment 2: small test of vacuum potassium carbonate method desulfurization and decyanation waste liquid treatment, each batch processing capacity is 1L, the total cyanide concentration of the original waste liquid is 10704mg / L, S 2- It is 3120mg / L. After adding ferrous sulfate to react, the temperature is 50°C, the pH is 6, and the cyanide in the effluent is about 500mg / L, S 2- It is less than 15mg / L, and the removal rate is greater than 95%. Add NaOH after precipitation and filtration, react at 90°C to form yellow blood salt, crystallize at 15°C, and recover about 18g of yellow blood salt per liter of wastewater.

Embodiment 3

[0030] Embodiment 3: small test of vacuum potassium carbonate method desulfurization and decyanation waste liquid treatment, each batch processing capacity is 1L, the total cyanide concentration of the original waste liquid is 655mg / L, S 2- It is 306mg / L. After adding ferrous chloride to react, the temperature is 30°C, the pH is 7, and the cyanide in the effluent is about 30mg / L, S 2- The removal rate is less than 1.5mg / L, and the removal rate is greater than 95%. After precipitation and filtration, add KOH, react at 95°C to form yellow blood salt, crystallize at 20°C, and recover about 1.4g of yellow blood salt per liter of wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com