Treatment method of wastewater from methyl methacrylate plant

A technology of methyl methacrylate and a treatment method, which is applied in the field of wastewater treatment of methyl methacrylate plants, can solve problems such as easy polymerization of methyl methacrylate, and achieve the effects of solving easy polymerization and inhibiting polymerization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take the wastewater from a methyl methacrylate plant in a domestic factory, and adjust the p H value of the methyl methacrylate wastewater to 10 by adding alkali.

[0032] The rectification process is that the total height of the rectification tower packing is 52cm (26 trays), the height of the rectification section is 12cm (6 trays), the height of the stripping section is 40cm (20 trays), and the temperature of the tower still 101°C, tower top temperature 72°C, reflux ratio 4:1, operating pressure at normal pressure, continuous sampling 10 times to analyze wastewater COD value and pH value, the results are shown in Table 1.

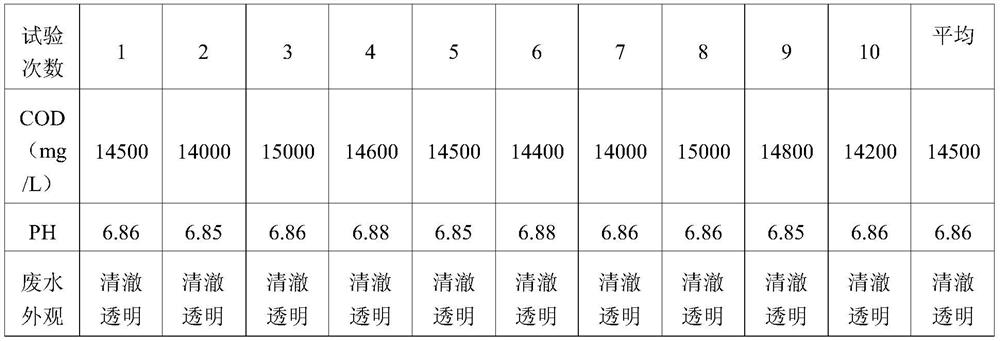

[0033] Table 1 Wastewater COD, p H and appearance

[0034]

[0035] The data in Table 1 shows that the treated wastewater was continuously sampled 10 times, the average COD was 14,500, and the average pH was 6.86. The appearance of the wastewater was clear and transparent, which met the requirements of the biochemical treatment of the device. ...

Embodiment 2

[0037] Take the wastewater from a methyl methacrylate plant in a domestic factory, and adjust the p H value of the methyl methacrylate wastewater to 9.7 by adding alkali.

[0038] The rectification process is that the total height of the rectification tower packing is 52cm (26 trays), the height of the rectification section is 12cm (6 trays), the height of the stripping section is 40cm (20 trays), and the temperature of the tower still 101°C, tower top temperature 72°C, reflux ratio 4:1, operating pressure at normal pressure, continuous sampling 10 times to analyze wastewater COD value and pH value, the results are shown in Table 2.

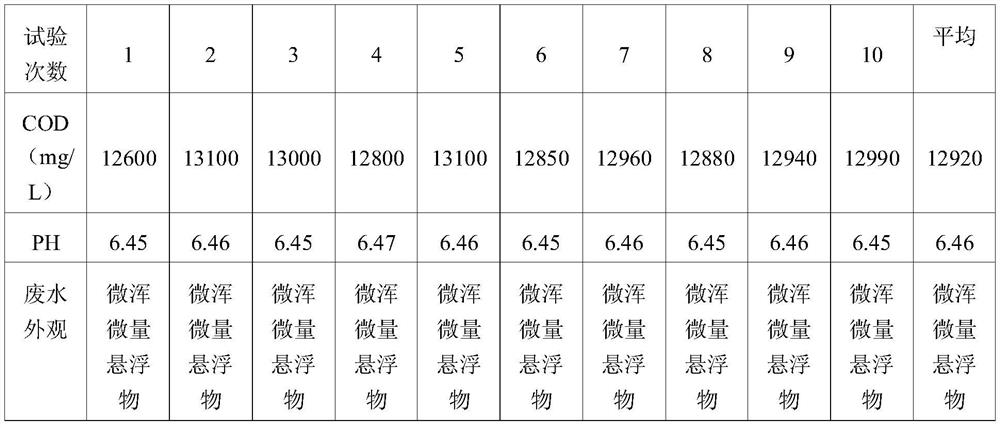

[0039] Table 2 Wastewater COD, p H and appearance

[0040]

[0041] The data in Table 2 shows that the treated wastewater was continuously sampled 10 times, the average COD was 12920, the average pH was 6.46, and the wastewater was slightly muddy with traces of suspended solids, which basically met the requirements of the biochemical treatment...

Embodiment 3

[0043] The pH value of methyl methacrylate wastewater was adjusted to 10.3 by adding alkali.

[0044] The rectification process is that the total height of the rectification tower packing is 52cm (26 trays), the height of the rectification section is 12cm (6 trays), the height of the stripping section is 40cm (20 trays), and the temperature of the tower still 101°C, tower top temperature 72°C, reflux ratio 4:1, operating pressure at normal pressure, continuous sampling 10 times to analyze wastewater COD value and pH value, the results are shown in Table 3.

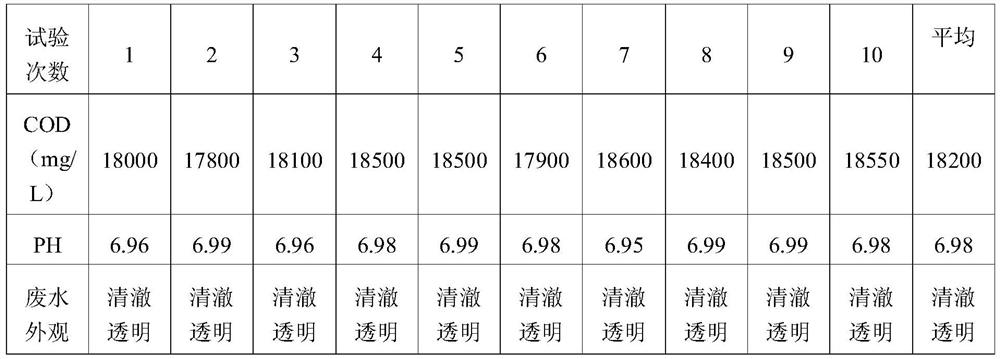

[0045] Table 3 Wastewater COD, p H and appearance

[0046]

[0047]The data in Table 3 shows that the treated wastewater was continuously sampled 10 times, the average COD was 18200, the average pH was 6.98, and the appearance of the wastewater was clear and transparent. The risk of 20000mg / L basically meets the biochemical treatment requirements of the device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com