Hole group processing method for flexible guide rail based on coordinate system of hole-making equipment

A technology of equipment coordinate system and flexible guide rail, which is applied in the field of mechanical processing to achieve the effect of improving processing efficiency and simplifying calculation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

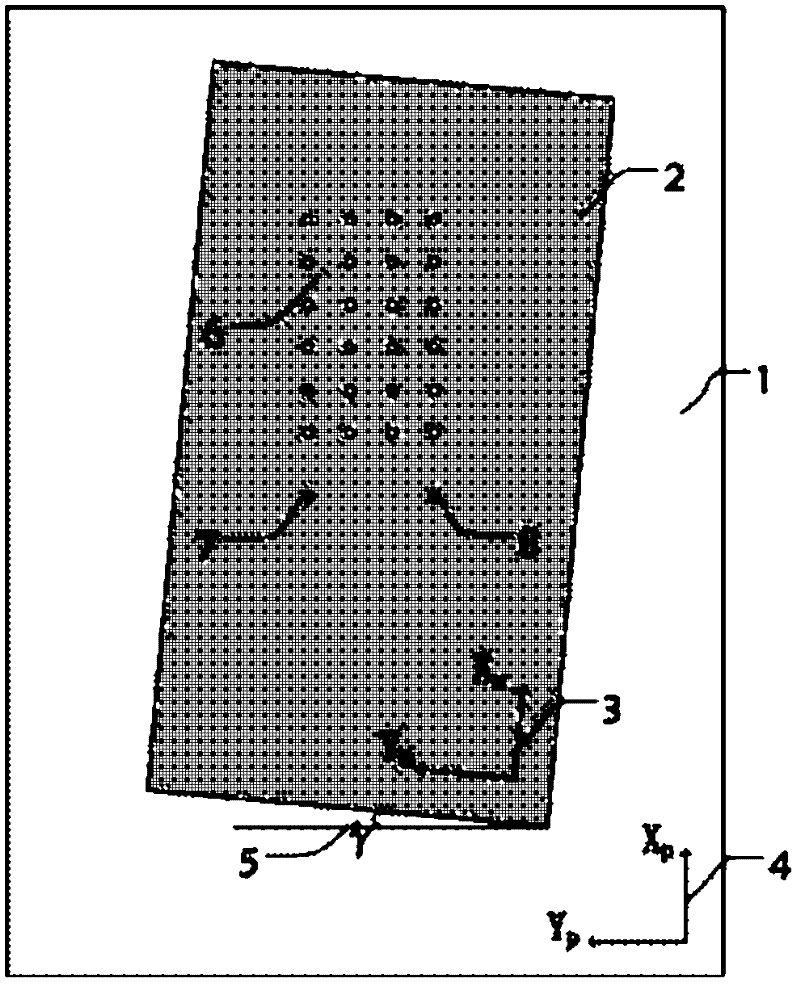

[0018] like figure 1 As shown, the application environment of this embodiment includes: workpiece 1 and equipment processing range 2, 3 is the machine tool coordinate system related to the machine tool hardware, 4 is the workpiece coordinate system related to the workpiece, the value of γ angle 5 is the value of the deflection angle, That is, the included angle between Xm and Xp, 6 is a group of holes to be processed, 7 and 8 are two process positioning K holes respectively.

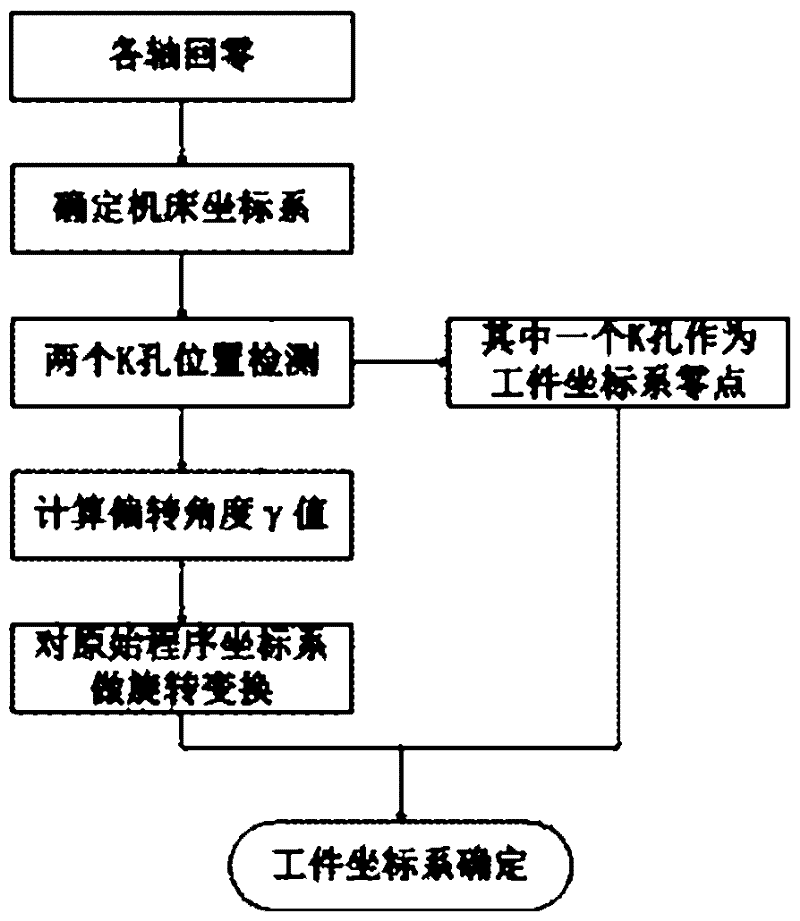

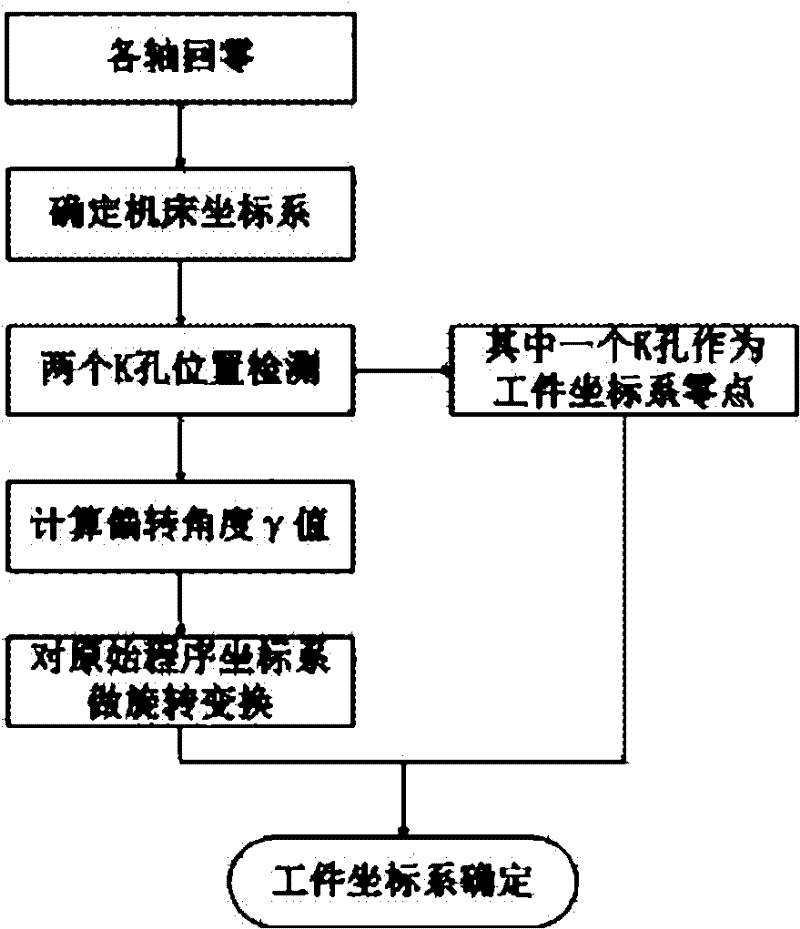

[0019] like figure 2 As shown, the process of this embodiment includes:

[0020] The first step, the process of returning to zero for each axis, determines the coordinate system of the machine tool: make the X-axis and Y-axis of the machine tool automatically return to zero. After the zero point of each machine tool axis is determined, the direction of each axis is the direction of the axis according to the direction limited by each axis of the equipment itself. At this time, the coordinate system of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com