Method for measuring content of carbonyl oxygen-containing functional groups on surface of carbon black

A functional group and carbon black technology, applied in the field of determination of carbonyl oxygen-containing functional group content, can solve problems such as large-scale equipment and complex calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0074] Specific embodiment one: the method for measuring the carbonyl oxygen-containing functional group content on the surface of carbon black in this embodiment is implemented according to the following steps:

[0075] Step 1. Configuration and calibration of standard solution

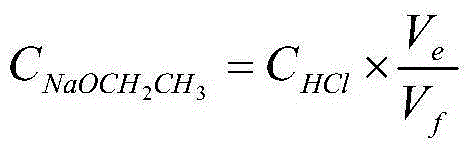

[0076] Prepare and calibrate 0.1mol / L HCl standard solution, 0.1mol / L NaOH standard solution and 0.1mol / L NaOCH 2 CH 3 standard solution;

[0077] Step 2. Sample determination

[0078] ①. Take carbon black with a particle size of ≤75 μm, dry it in a vacuum oven at 120°C for 36 hours, and store it in a desiccator;

[0079] ②. Weigh 2 carbon black samples with an electronic balance and place them in No. 1 flask and No. 2 flask respectively; add excess 0.1mol / L NaOCH to No. 1 flask 2 CH 3 Standard solution, add excess 0.1mol / L NaOH standard solution to the No. 2 flask, ultrasonically disperse the solutions in the two flasks for 20 minutes, and reflux for 1.5h to 3h;

[0080] ③. Then add 0.1mol / L H...

specific Embodiment approach 2

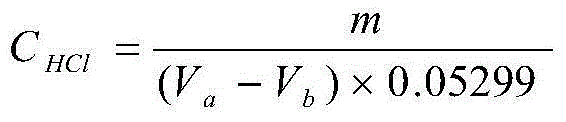

[0107] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the configuration and calibration of the HCl standard solution described in step one are carried out according to the following steps:

[0108] 1. Measure 8.4 mL of concentrated hydrochloric acid with a mass fraction of 37% and add it to 1000 mL of distilled water, shake well to obtain a hydrochloric acid solution;

[0109] 2. Burn anhydrous sodium carbonate at 270°C to constant weight, weigh 0.2g, accurate to 0.0001g, dissolve in 50mL of distilled water, add 10 drops of bromocresol green-methyl red mixed indicator;

[0110] 3. Titrate with the prepared hydrochloric acid solution until the solution changes from green to dark red, boil for 2 minutes, continue titrating after cooling to make the solution dark red again;

[0111] 4. Blank test: add 50mL distilled water to the Erlenmeyer flask, drop 10 drops of bromocresol green-methyl red mixed indicator, titrate with the prepar...

specific Embodiment approach 3

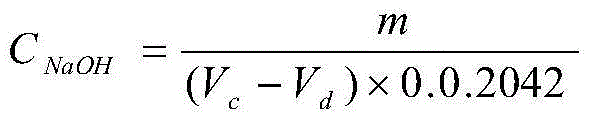

[0120] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the configuration and calibration of the NaOH standard solution described in step one are carried out according to the following steps:

[0121] 1. Weigh 4.0g of sodium hydroxide, accurate to 0.0001g, put it in a plastic beaker, pour it into 1000mL of carbon dioxide-free water, shake it well and dissolve it to get NaOH solution;

[0122] 2. Dry the benchmark potassium hydrogen phthalate at 110°C to constant weight, weigh 0.6g, accurate to 0.0001g, dissolve it in 50mL of carbon dioxide-free water, add 2 drops of phenolphthalein indicator solution, and use step 1 Titrate the NaOH solution prepared in , until the solution is pink and keeps 30s without fading;

[0123] 3. Blank test: Add 50mL of carbon dioxide-free water to the Erlenmeyer flask, add 2 drops of phenolphthalein indicator solution, and titrate with the NaOH solution prepared in step 1 until the solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com