Method for recovering iron and phosphorus from steelmaking slag

A technology for steelmaking slag and iron recovery, which is applied in the direction of recycling technology, process efficiency improvement, manufacturing converters, etc., can solve the problems of limited recirculation, impaired dephosphorization agent function, etc., and achieve the effect of effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

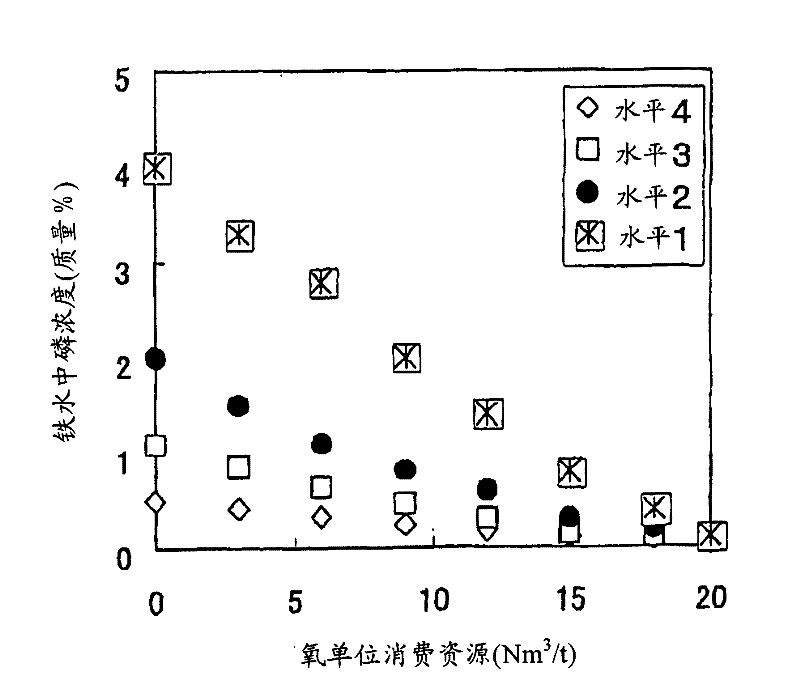

Image

Examples

Embodiment 1

[0073] The blast furnace molten iron tapped from the blast furnace is ironed (milled) by a torpedo car. The blast furnace molten iron stored in the torpedo car is subjected to desiliconization and pre-dephosphorization treatment, and then the blast furnace molten iron is transferred to the molten iron tank. The blast furnace hot metal is desulfurized by mechanical agitation, the desulfurized blast furnace hot metal is put into a converter, and decarburized and refined in the converter. Thus, the present invention is applied to the ironmaking-steelmaking process of melting molten steel from blast furnace hot metal. Table 3 shows examples of chemical components of blast furnace molten iron and molten steel from tapping in the blast furnace to completion of decarburization and refining in the converter.

[0074] [table 3]

[0075]

[0076] As shown in Table 3, the blast furnace molten iron after desiliconization and dephosphorization contains 0.05% by mass of phosphorus, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com