Structure and Processing Technology of Electronic Product Shell

A technology for electronic products and processing technology, applied in the field of housing and its processing technology, can solve the problems of inability to form structural parts, poor radiation protection performance, and reduce the strength of the housing, and achieve light weight, easy structural processing, and good radiation protection performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

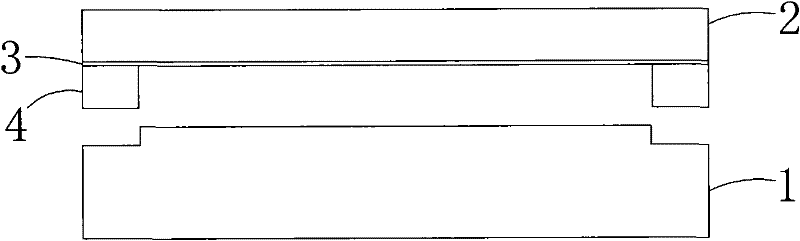

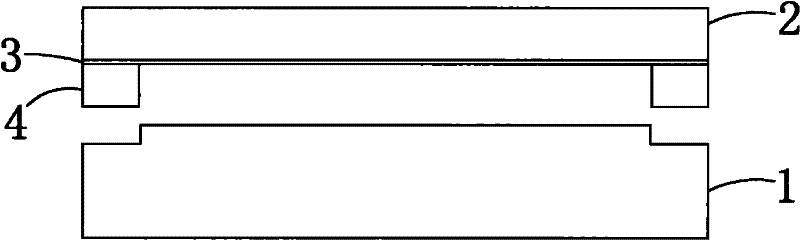

[0023] Embodiment: the structure and processing technology of a kind of shell of electronic product 1:

[0024] A. Preform: stack the sheet-like composite materials according to the set thickness and strength to form a composite material laminate 5, wherein the composite material is a fiber composite material (including carbon fiber and glass fiber) or a resin composite material.

[0025] B. Sticking film: Paste a hot melt adhesive film 3 on one surface of the laminated composite material, the thickness of the pasted hot melt adhesive film is 0.01-0.2 mm.

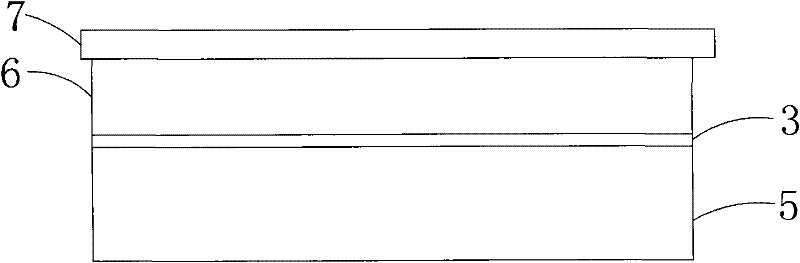

[0026] C. Wind pressure forming: put the laminated composite material with the hot melt adhesive film into the mold, put the side with the hot melt adhesive film up, and then put the profiling block 6 (silica gel or metal material) to ensure that the profiling block Completely press the laminated composite material with hot-melt adhesive film, then spread the sealing film 7 on the profiling block, then close the mold, heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com