Rapid high-rebound high-heat-preservation floccus flake and preparation method thereof

A flock and elastic technology, which is applied in the field of fast, high resilience and high thermal insulation flakes and its preparation, can solve the problems of decreased thermal insulation rate, easy hardening, poor compression resilience, etc., and achieves improved thermal insulation rate, good compression and resilience. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

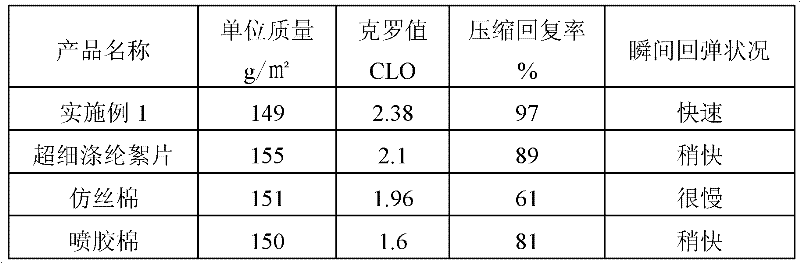

Examples

Embodiment 1

[0036] Embodiment 1, the preparation of elastic warm-keeping wadding

[0037] 1. Raw materials (preferred)

[0038] 0.78dtex×32mm superfine polyester fiber, 15 parts by mass;

[0039] 1.67dtex×38mm velvet fiber, 25 parts by mass;

[0040] 2. 22dtex×51mm PET / PBT composite elastic fiber, 5 parts by mass;

[0041] 4.0dtex×51mm low melting point composite fiber (melting point is 150°C), 7 parts by mass;

[0042] 1. 33dtex×38mm ordinary polyester fiber, 16 parts by mass;

[0043] 6.64dtex×64mm ordinary hollow polyester fiber, 16 parts by mass.

[0044] 2. Process

[0045] The production process of non-woven fabrics is adopted, and the steps are: mixing, initial opening, fine opening, carding, web laying, glue spraying, drying, cooling, edge trimming, winding, and cutting to form finished flake rolls.

[0046] Among them, the drying adopts progressive, three-layer drying room, the temperature of the bottom layer is controlled at 115°C, the temperature of the middle layer is co...

Embodiment 2

[0054] Embodiment 2, the preparation of elastic warm-keeping wadding

[0055] 1. Raw materials (minimum)

[0056] 20 parts by mass of 0.78dtex×40mm superfine polyester fiber;

[0057] 1.56dtex × 40mm specification Bolai velvet fiber 15 parts by mass;

[0058] 2. 10 parts by mass of PET / PBT composite elastic fiber of 22dtex×38mm;

[0059] 8 parts by mass of 4.0dtex×38mm low melting point composite fiber (melting point is 150°C);

[0060] 10 parts by mass of ordinary polyester fiber with specifications of 1.8dtex×51mm;

[0061] 15 parts by mass of ordinary hollow polyester fiber with a fineness of 5.33dtex×54mm.

[0062] 2. Process

[0063] The method is the same as that described in Example 1, except that in the drying step, the temperature of the bottom layer is controlled at 110°C, the temperature of the middle layer is controlled at 130°C, and the temperature of the upper layer is controlled at 155°C.

[0064] 3. Effect of flakes: There is no significant difference with ...

Embodiment 3

[0065] Embodiment 3, the preparation of elastic warm-keeping wadding

[0066] 1. Raw materials (maximum)

[0067] 25 parts by mass of superfine polyester fiber of 0.78dtex×51mm;

[0068] 1. 20 parts by mass of velvet fiber with specifications of 60dtex×51mm;

[0069] 2. 22dtex×40mm PET / PBT composite elastic fiber 15 parts by mass;

[0070] 10 parts by mass of 4.0dtex×40mm low melting point composite fiber (melting point is 150°C);

[0071] 1.50dtex×40mm specification ordinary polyester fiber 25 parts by mass;

[0072] 25 parts by mass of ordinary hollow polyester fiber of 6.64dtex×60mm size.

[0073] 2. Process

[0074] The method is the same as that described in Example 1, except that in the drying step, the temperature of the bottom layer is controlled at 120°C, the temperature of the middle layer is controlled at 145°C, and the temperature of the upper layer is controlled at 170°C.

[0075] 3. Effect of flakes: There is no significant difference with the effect of fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com