A kind of titanium dioxide nanotube array film and preparation method thereof

A technology of nanotube array and titanium dioxide, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as unsatisfactory photocatalytic performance, improve photocatalytic activity and electrical conductivity, and carbon-nitrogen co-doping Or the effect of uniform carbon doping and uniform content distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

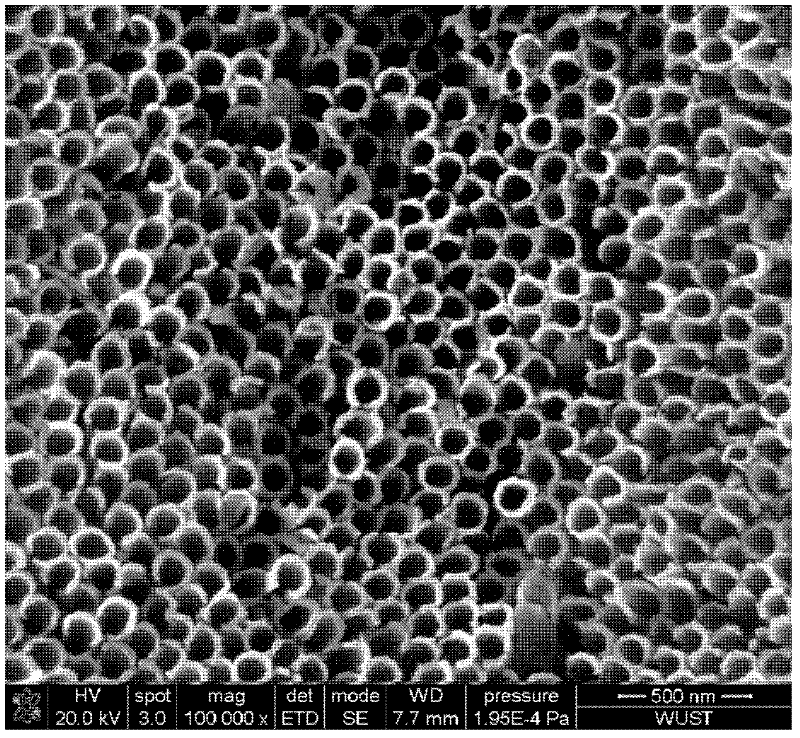

[0023] A titanium dioxide nanotube array film and a preparation method thereof. First, grind and polish a titanium-containing metal sheet with a titanium content of 50-70wt% as an anode, put it into the electrolyte, and anodize it under the condition of a controlled voltage of 20-40V for 0.5-2 hours; then anodize the titanium-containing metal sheet The sheet is taken out from the electrolyte, placed in a high-temperature furnace, and kept in a protective atmosphere at 400-600°C for 5-8 hours; then cooled to room temperature with the furnace in a protective atmosphere, and the surface of the cooled titanium-containing metal sheet Generation of carbon-doped titanium dioxide nanotube array films.

[0024] The protective atmosphere in this embodiment is Ar.

[0025] In this embodiment: the electrolyte is 0.8 to 1.5 wt% of fluorine-containing ions, 1 to 15 wt% of H 2 A mixed solution of O and 84-98 wt% alcoholic organic solvent; wherein: fluorine-containing ions are HF, and the a...

Embodiment 2

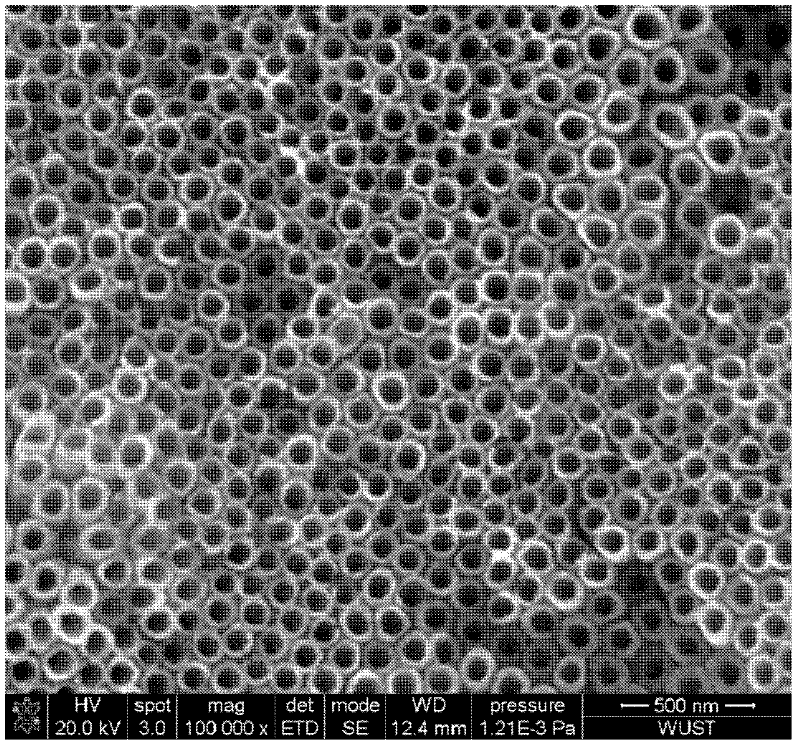

[0027] A titanium dioxide nanotube array film and a preparation method thereof.

[0028] The protective atmosphere of this embodiment is N 2 .

[0029] In the electrolyte solution of this embodiment: the fluorine-containing ion is NH 4 F, alcoholic organic solvent is ethanol.

[0030] All the other are with embodiment 1.

Embodiment 3

[0032] A titanium dioxide nanotube array film and a preparation method thereof.

[0033] The protective atmosphere of this embodiment is N 2 and Ar.

[0034] In the electrolyte solution of this embodiment: the fluorine-containing ion is NH 4 F and HF, alcoholic organic solvents are ethanol and ethylene glycol.

[0035] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com