Method for preparing tungsten coating by using cold air dynamic spraying technology

A cold air power spraying and coating technology is applied in the field of preparing coatings and high melting point metal tungsten coatings. The effect of low content and low residual tensile stress in the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

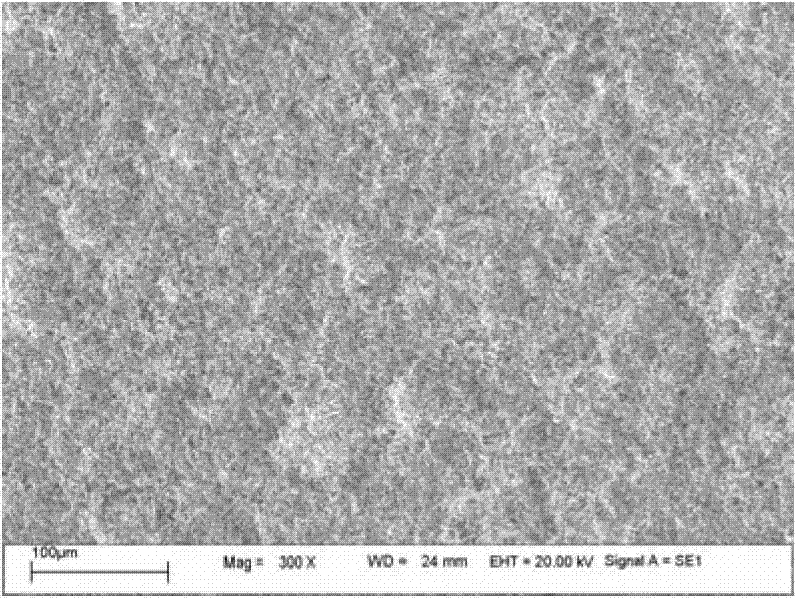

[0031] The copper alloy used for air-conditioning power spraying is commercially available. The sample size is 20mm×30mm×10mm. The sprayed surface is degreased with acetone, ultrasonically cleaned with anhydrous ethanol, dehydrated and dried, and finally the surface is sandblasted with a sandblasting machine deal with.

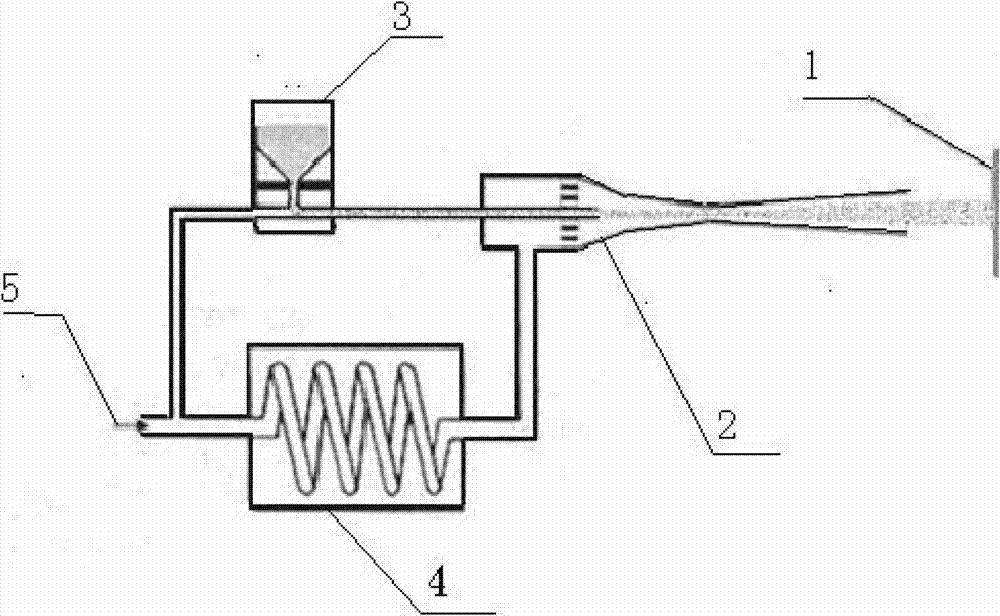

[0032] Put the treated sample on the jig for cold air power spraying, and then use cold air power spraying equipment Kinetic 3000 for cold spraying, using nitrogen as the carrier gas and accelerating gas, the process parameters are spraying temperature 730 ° C, pressure 32.2bar, The air flow is 75.0m 3 / h, the spraying distance is 30mm, and the powder feeding amount is 20g / min. The surface morphology of the sprayed samples is as follows figure 2 shown.

Embodiment 2

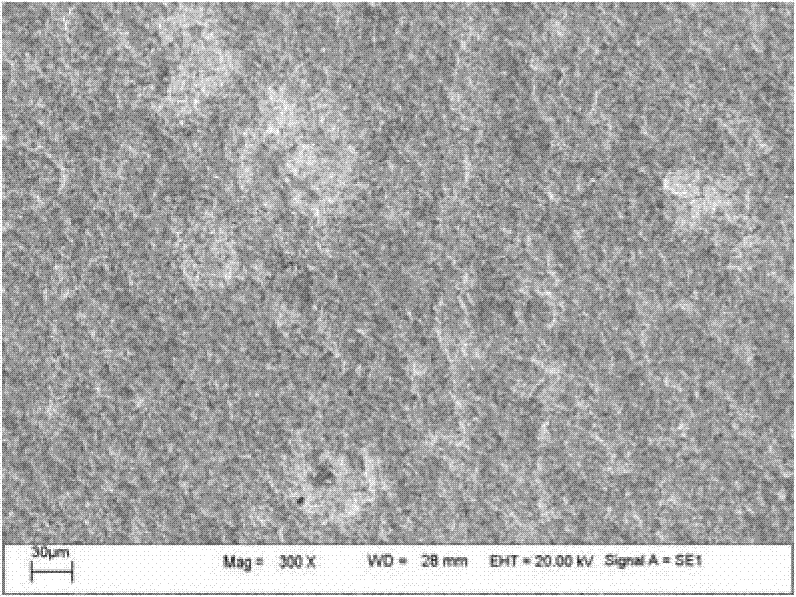

[0034] The 316L stainless steel used in air-conditioning power spraying is commercially available, and the sample size is 20mm×30mm×10mm. The sprayed surface is degreased with acetone, ultrasonically cleaned with anhydrous ethanol, dehydrated and dried, and finally the surface is sandblasted with a sandblasting machine deal with.

[0035] Put the processed sample on the fixture for cold air power spraying, and then use cold air power spraying equipment Kinetic 3000 for cold spraying, using nitrogen as the carrier gas and accelerating gas, the process parameters are spraying temperature 500 ° C, pressure 20bar, gas The flow rate is 70.0m 3 / h, the spraying distance is 50mm, and the powder feeding rate is 50g / min. The surface morphology of the sprayed samples is as follows image 3 shown.

Embodiment 3

[0037] The copper alloy used for air-conditioning power spraying is commercially available. The sample size is 20mm×30mm×10mm. The sprayed surface is degreased with acetone, ultrasonically cleaned with anhydrous ethanol, dehydrated and dried, and finally the surface is sandblasted with a sandblasting machine deal with.

[0038] Put the treated sample on the fixture of cold air power spraying, and then use cold air power spraying equipment KM-CDS for cold spraying, use helium as the carrier gas and acceleration gas, and the process parameters are spraying temperature of 250°C and pressure of 10bar , the air flow is 75.0m 3 / h, the spraying distance is 10mm, and the powder feeding amount is 10g / min. The surface morphology of the sprayed samples is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com