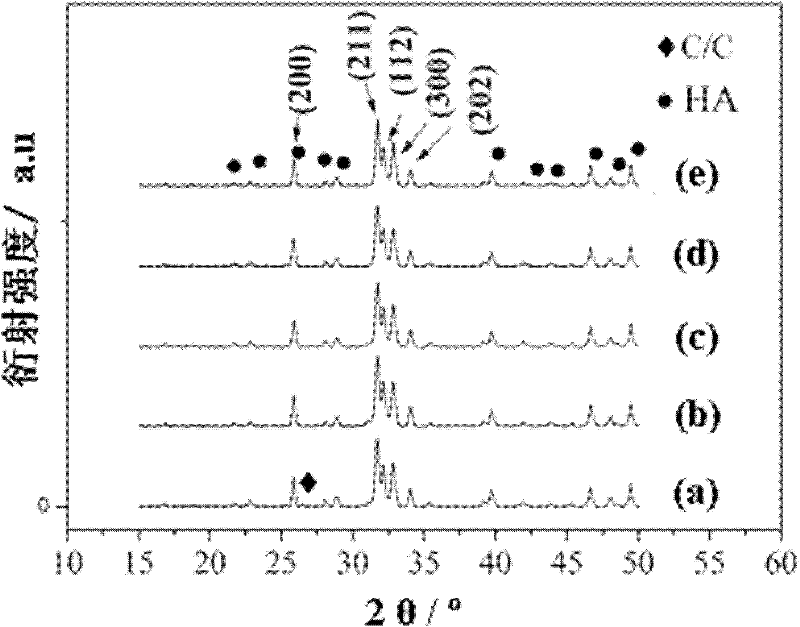

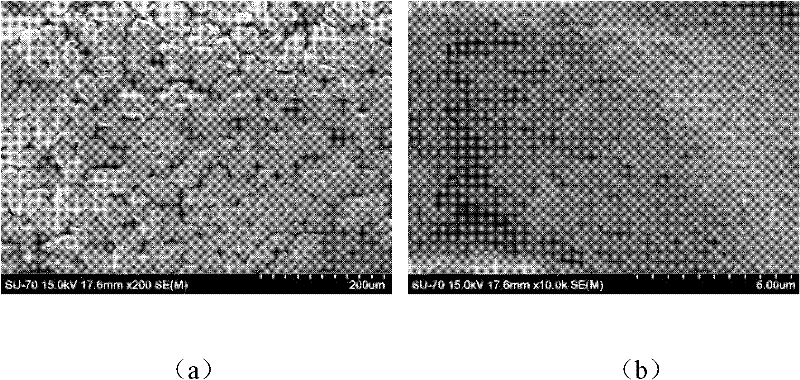

A kind of preparation method of carbon/carbon composite material containing silicon hydroxyapatite coating

A technology of silicon hydroxyapatite and carbon composite materials, which is applied in metal material coating technology, coating, medical science, etc., can solve the problems of peeling failure, high C/C density, etc., and achieve good crystallinity and high hardness and the effect of binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) At first, add the sodium perchlorate solution that concentration is 0.5mol / L in hydrothermal kettle, then make the density be 1.3g / cm 3 The carbon / carbon composite material was placed in a hydrothermal kettle, hydrothermally treated at 80°C for 24 hours, then taken out, ultrasonically cleaned with distilled water, and dried;

[0024] 2) Place the carbon / carbon composite material treated in step 1) in a mixed aqueous solution containing 0.15 mol / L calcium acetate and 0.1 mol / L ammonium dihydrogen phosphate at a flow rate of 200 ml / min, and pass the oscillation frequency at 1.1 MHz, an ultra-high frequency induction heating power supply with an oscillating current of 300A heats the carbon / carbon composite material, and deposits for 1.5 hours to deposit a calcium hydrogen phosphate coating on the surface;

[0025] 3) Place the carbon / carbon composite material deposited with the calcium hydrogen phosphate coating obtained in step 2) in an aqueous ammonia solution with a ...

Embodiment 2

[0028] 1) At first, add the sodium perchlorate solution that concentration is 1.5mol / L in hydrothermal kettle, then make the density be 1.5g / cm 3 The carbon / carbon composite material was placed in a hydrothermal kettle, hydrothermally treated at 100°C for 20 hours, then taken out, ultrasonically cleaned with distilled water and dried;

[0029] 2) Place the carbon / carbon composite material treated in step 1) in a mixed aqueous solution containing 0.3 mol / L calcium acetate and 0.08 mol / L ammonium dihydrogen phosphate at a flow rate of 800 ml / min, and pass the vibration frequency at 1.1 MHz, an ultra-high frequency induction heating power supply with an oscillating current of 500A heats the carbon / carbon composite material, and deposits for 1 hour to deposit a calcium hydrogen phosphate coating on the surface;

[0030] 3) Place the carbon / carbon composite material deposited with the calcium hydrogen phosphate coating obtained in step 2) in an aqueous ammonia solution with a mass ...

Embodiment 3

[0033] 1) At first, add a sodium perchlorate solution with a concentration of 1.0mol / L in the hydrothermal kettle, and then add a solution with a density of 1.4g / cm 3 The carbon / carbon composite material was placed in a hydrothermal kettle, hydrothermally treated at 120°C for 12 hours, then taken out, ultrasonically cleaned with distilled water, and dried;

[0034]2) Place the carbon / carbon composite material treated in step 1) in a mixed aqueous solution containing 0.05 mol / L calcium acetate and 0.03 mol / L ammonium dihydrogen phosphate at a flow rate of 1.5 L / min. 1.1MHz, an ultra-high frequency induction heating power supply with an oscillating current of 600A heats the carbon / carbon composite material, and deposits it for 2 hours to deposit a calcium hydrogen phosphate coating on the surface;

[0035] 3) Place the carbon / carbon composite material deposited with the calcium hydrogen phosphate coating obtained in step 2) in an aqueous ammonia solution with a mass concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com