A kind of preparation method of zirconium-niobium alloy with α/β double state structure

A technology of zirconium-niobium alloy and structure, which is applied in the field of alloy material preparation to achieve the effect of increased strength and excellent tensile plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

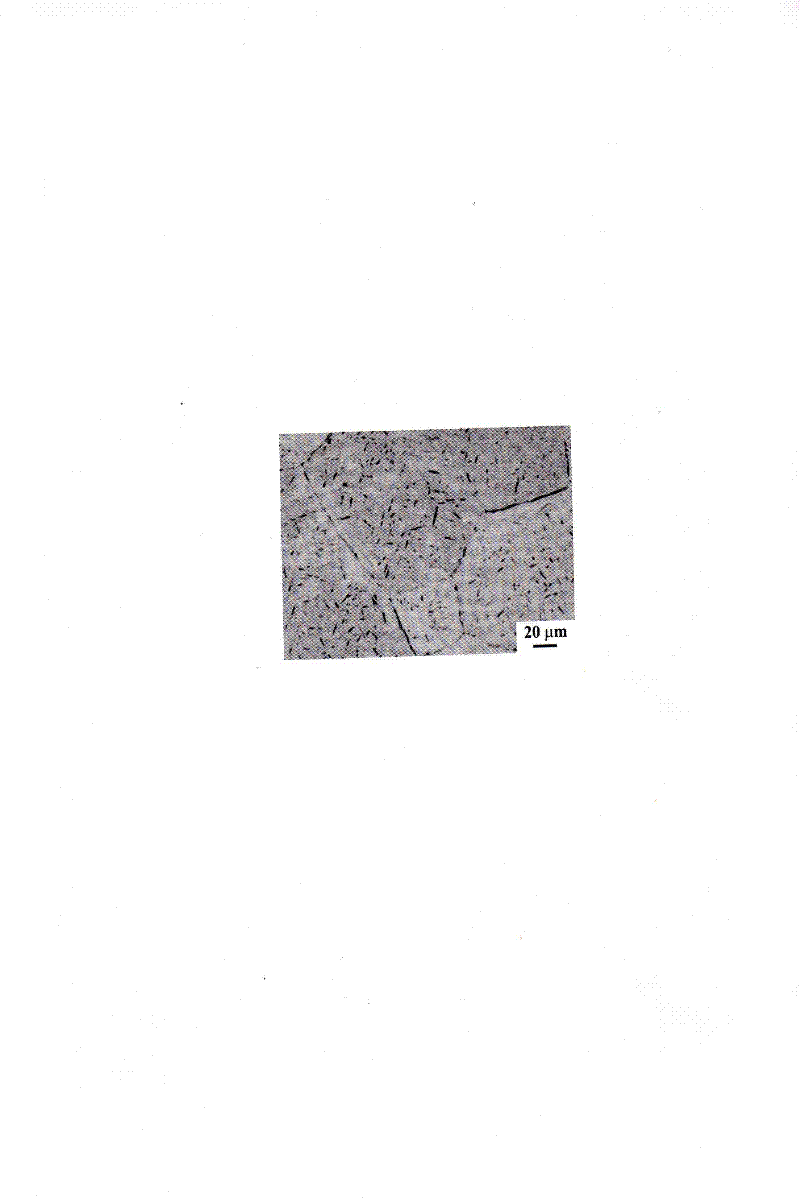

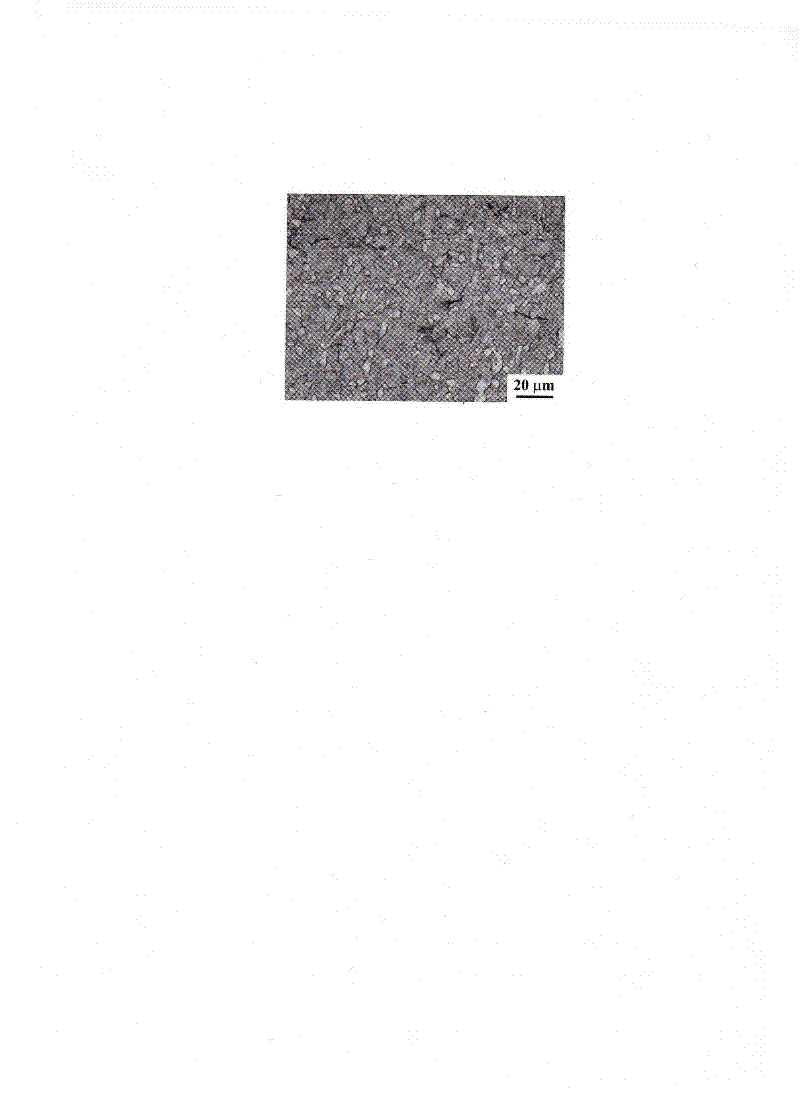

[0022] The Zr705 plate was first kept at 1000°C for 1 hour and then water quenched to obtain α-single-phase martensite, such as figure 1 shown. The above alloy at 600 o Rolling is carried out after 30 minutes of C heat preservation, the deformation amount is 60%, and air-cooled to room temperature after deformation. Then coat the surface of the deformed alloy with a layer of anti-oxidation and anti-decarburization coating (202 high-temperature anti-oxidation and anti-decarburization coating model 202, produced by Zhejiang Huangyan Special Coatings Factory, No. 230 Luting Road, Huangyan Economic Development Zone, Zhejiang Province), after drying Put it into a high-temperature furnace at a temperature of 900° C., keep it warm for 0.5 h, and then take it out and cool it to room temperature in air. A two-state structure composed of lamellar α / β structure with a volume fraction of equiaxed primary α phase of about 21% can be obtained, such as figure 2 shown. The equiaxed prima...

Embodiment 2

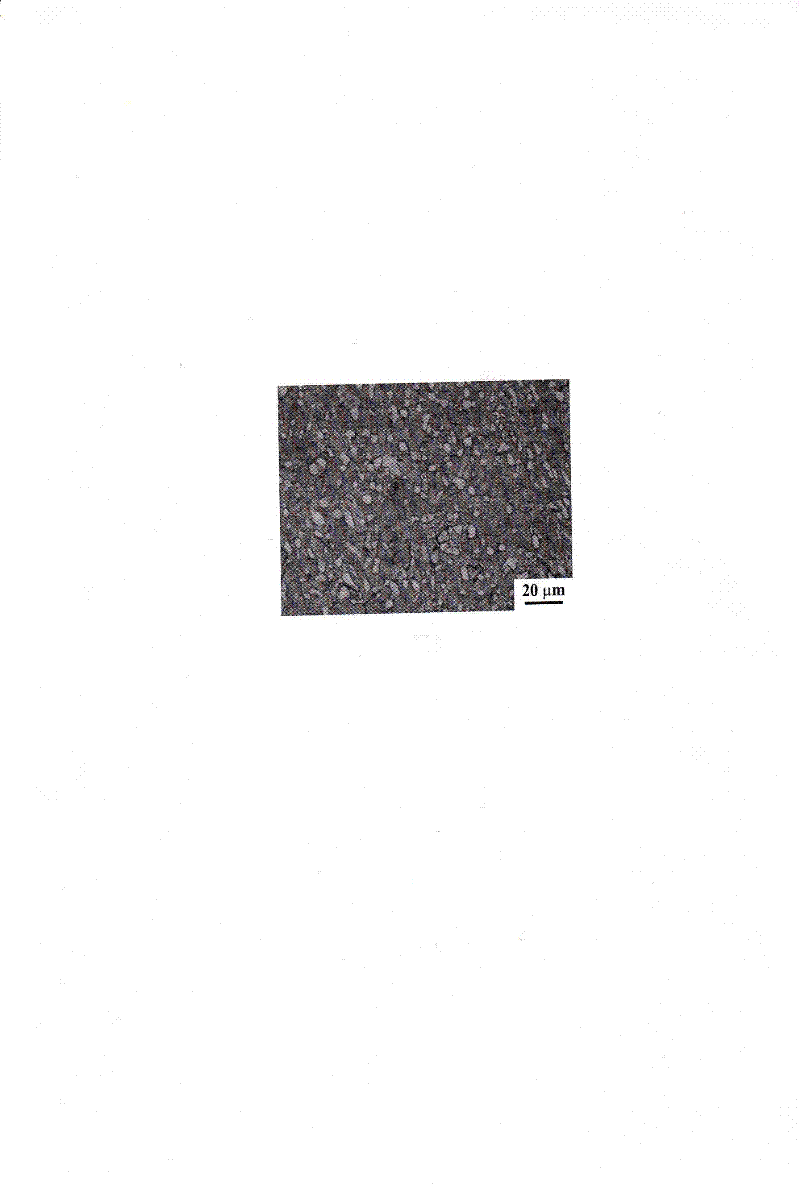

[0024] The Zr705 plate was firstly kept at 1050°C for 0.5h and then water quenched to obtain α single-phase martensite. Put the above alloy at 400 o Rolling is carried out after C is kept for 25 minutes, and the deformation amount is 40%. After deformation, it is air-cooled to room temperature. Then, coat the surface of the deformed alloy with a layer of anti-oxidation and anti-decarburization coating (high-temperature anti-oxidation and anti-decarburization coating, model JZ-403B, produced by Anqiu Huaxin Heat Treatment Material Factory, Economic and Technological Development Zone, Anqiu City, Shandong Province), and dry Finally, put it into a high-temperature furnace at a temperature of 850° C., keep it warm for 1.5 hours, and then take it out and air-cool it to room temperature. A two-state structure composed of lamellar α / β structure with a volume fraction of equiaxed primary α phase of about 30% can be obtained, such as image 3 shown. The equiaxed primary α-phase grai...

Embodiment 3

[0026] The Zr705 plate was firstly kept at 1000°C for 1 hour and then water quenched, and then kept at 600°C for 1 hour to obtain a basket-like structure, as shown in Figure 4 shown. The above alloy at 200 o C, after 20 minutes of heat preservation, rolling, the deformation amount is 50%, and air-cooled to room temperature after deformation. Coat the surface of the deformed alloy with a layer of anti-oxidation and anti-decarburization protective coating (high-temperature anti-oxidation and anti-decarburization protective coating, model KOC-02, Shanghai Runer Surface Material Co., Ltd., No. 2784, Cao'an Road, Shanghai). Put it into a high-temperature furnace at 850 °C, keep it warm for 1 hour, take it out and cool it to room temperature in air, and obtain a two-state structure with a volume fraction of equiaxed primary α phase of 36%, as shown in Figure 5 shown. The equiaxed α-phase grain size is 2-4 μm. The mechanical properties of the organization were tested, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com