A new type of aviation base oil

A base oil and aviation technology, applied in the field of aviation lubricating oil, can solve problems such as poor low-temperature pumpability and start-up performance, insufficient high-temperature performance and stability, and poor low-temperature performance, so as to improve service performance and stability, Effects of improving stability and safety and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] ①Raw material specification

[0038] N-valeric acid content ≥ 99.0% Color ≤ 30 black Zeng Iodine value 2 / 100g,

[0039] N-hexanoic acid content ≥ 99.0%, color ≤ 30 black Zeng, iodine value 2 / 100g,

[0040] N-heptanoic acid content ≥ 99.0% Color ≤ 30 black Zeng Iodine value 2 / 100g,

[0041] Nonanoic acid content ≥ 99.0% color ≤ 30 black Zeng iodine value 2 / 100g,

[0042] Pentaerythritol content ≥ 98.0%,

[0043] Trimethylol dioxane content ≥ 99.0%,

[0044] Activated carbon decolorization power ≥ 12;

[0045] ② Formula

[0046] Phase I Raw Materials

[0047] 143 kg of n-valeric acid, 36 kg of isovaleric acid, 81 kg of n-hexanoic acid, 409 kg of n-heptanoic acid, 51 kg of isooctanoic acid, 167 kg of n-nonanoic acid, 91 kg of pentaerythritol, 191 kg of trimethylolpropane, 12 kg of activated carbon ;

[0048] Phase II Raw Materials

[0049] 114 kg of n-valeric acid, 28 kg of isovaleric acid, 65 kg of n-hexanoic acid, 328 kg of n-heptanoic acid, 40 kg of isoocta...

Embodiment 2

[0054] Raw material is as described in the table below, and all the other are with embodiment 1.

[0055] raw material

Phase 1 (kg)

Phase II (kg)

n-valeric acid

143

114

Isovaleric acid

36

28

81

65

n-heptanoic acid

409

328

isooctanoic acid

51

40

167

133

91

191

12

[0056] The deacidification reaction in this example is carried out with reference to the method and equipment provided in "Research on Deacidification of High-acid Crude Oil by Heat Treatment" published by Shen Haiping and others in "Petroleum Refining and Chemical Industry" Volume 35 No. 2 in February 2004 operation.

[0057] The resulting product properties:

[0058]

[0059] Odd-numbered fatty acids in ester oils have lower pour point and pour point. ...

Embodiment 3-17

[0061] The preparation method is the same as in Example 1, and the detailed raw material ratio is shown in the table below, and the numbers of Examples 3-17 are ABCD...I-3.

[0062]

[0063]

[0064]

[0065]

[0066] The performance of the product of the present invention will be further described below by taking the detection data of Example 1 of the present invention as an example.

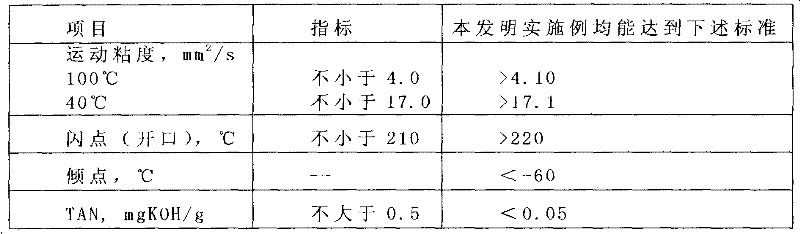

[0067] Table I: Consistency check of Embodiment 1 of the present invention.

[0068]

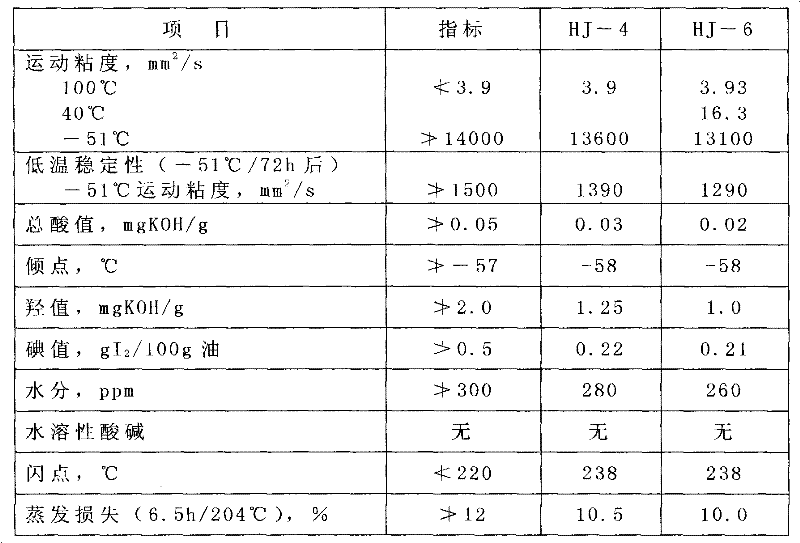

[0069] Table II physical and chemical and performance requirements.

[0070]

[0071] Note:

[0072] 1 was titrated to an endpoint of pH 11.

[0073] 2 Not more than 6% compared with the result measured in 35 minutes.

[0074] 3 The test time is 6.5 hours, and the bath temperature is 205±1°C. Using ASTM E1-67 No. 80-F thermometer, the air temperature is maintained at 205 ± 1 °C and preheated if necessary.

[0075] 4mg / in 2 Multiply by 1.55 to convert to g / m 2 .

[0076] 5 In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com