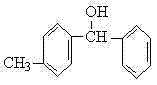

A kind of preparation method of pharmaceutical intermediate p-methylbenzhydryl alcohol

A technology of p-methylbenzophenone and p-methylbenzophenone, which is applied in the field of preparation of pharmaceutical intermediate p-methylbenzophenone, can solve the problem of incomplete conversion of benzophenone compounds, complicated operation process, Long reaction time and other problems, to achieve the effect of high product yield, high purity and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a three-necked reaction flask equipped with an electric stirrer, a reflux condenser, and a thermometer, add 40 mL of solvent, 19.6 g of p-methylbenzophenone, 13.3 g of sodium borohydride, and 0.8 g of a phase transfer catalyst. After the addition, start stirring, Control the reaction temperature at 20-40°C, stir vigorously for 4 hours, and stop the reaction after the liquid chromatography traces the reaction to be complete. Add 40mL of water to the reaction bottle, and a white precipitate will appear. Filter to obtain the crude product of p-methylbenzhydryl alcohol, the crude product After drying, ethanol is recrystallized to obtain refined p-methylbenzhydryl alcohol product. The yield of p-methylbenzhydryl alcohol reaches 97.59%, and the melting point is 50-54°C.

Embodiment 2

[0022] In a three-necked reaction flask equipped with an electric stirrer, a reflux condenser, and a thermometer, add 40 mL of solvent, 19.6 g of p-methylbenzophenone, 15.2 g of sodium borohydride, and 0.8 g of a phase transfer catalyst. After the addition, start stirring, Control the reaction temperature at 20-40°C, stir vigorously for 4 hours, and stop the reaction after the liquid chromatography traces the reaction to be complete. Add 40mL of water to the reaction bottle, and a white precipitate will appear. Filter to obtain the crude product of p-methylbenzhydryl alcohol, the crude product After drying, ethanol is recrystallized to obtain refined p-methylbenzhydryl alcohol product, the yield of p-methylbenzhydryl alcohol reaches 98.07%, and the melting point is 50-54°C.

Embodiment 3

[0024] In a three-necked reaction flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 40 mL of solvent, 19.6 g of p-methylbenzophenone, 17.1 g of sodium borohydride, and 0.8 g of a phase transfer catalyst. After the addition, start stirring, Control the reaction temperature at 20-40°C, stir vigorously for 4 hours, and stop the reaction after the liquid chromatography traces the reaction to be complete. Add 40mL of water to the reaction bottle, and a white precipitate will appear. Filter to obtain the crude product of p-methylbenzhydryl alcohol, the crude product After drying, recrystallize ethanol to obtain refined p-methylbenzhydryl alcohol product. The yield of p-methylbenzhydryl alcohol reaches 97.38%, and the melting point is 50-54°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com