Preparation method for resin curing agent N-acetoacetyl morpholine

A technology of acetoacetylmorpholine and resin curing, applied in organic chemistry and other directions, to achieve the effects of high product purity, simple separation and purification process, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

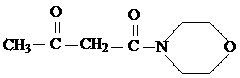

Image

Examples

Embodiment 1

[0013] In a 250mL four-necked flask, add 50g of solvent, 17.4g of morpholine, 0.4g of polymerization inhibitor, and 17.7g of diketene, install a reflux condenser and a thermometer, start the stirrer, control the temperature at 85-100°C, and the reaction time is 6 -10h, after the reaction is over, distill off most of the solvent under normal pressure, and distill the remaining organic phase under reduced pressure, first distill off the remaining solvent and unreacted raw materials, and then collect the fraction at 114-116°C / 1.65kPa , to obtain the N-acetoacetylmorpholine product, and the product yield is 93.51%.

Embodiment 2

[0015] In a 250mL four-necked flask, add 50g of solvent, 17.4g of morpholine, 0.5g of inhibitor, and 21g of diketene, install a reflux condenser, a thermometer, start the stirrer, control the temperature at 85-100°C, and the reaction time is 6- After 12 hours, after the reaction, most of the solvent was distilled off under normal pressure, and the remaining organic phase was distilled off under reduced pressure. First, the remaining solvent and unreacted raw materials were distilled off, and then the fraction at 114-116°C / 1.65kPa was collected. The N-acetoacetylmorpholine product was obtained, and the product yield was 93.92%.

Embodiment 3

[0017] In a 250mL four-neck flask, add 50g of solvent, 17.4g of morpholine, 0.7g of polymerization inhibitor, and 21g of diketene, install a reflux condenser and a thermometer, start the stirrer, control the temperature at 85-100°C, and the reaction time is 6- After 12 hours, after the reaction, most of the solvent was distilled off under normal pressure, and the remaining organic phase was distilled off under reduced pressure. First, the remaining solvent and unreacted raw materials were distilled off, and then the fraction at 114-116°C / 1.65kPa was collected. The N-acetoacetylmorpholine product was obtained, and the product yield was 93.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com