A tube-and-tube nano-titanium dioxide tube array photocatalytic reactor and preparation method thereof

A technology of nano-titanium dioxide and photocatalytic reactor, which is applied in chemical instruments and methods, chemical/physical/physicochemical processes of energy application, chemical/physical processes, etc. It can solve the problem that the low temperature conditions of the solution system are difficult to control and it is difficult to obtain photocatalysts , environmental pollution and other issues, to achieve rapid and efficient photocatalytic degradation treatment, strong redox, and easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

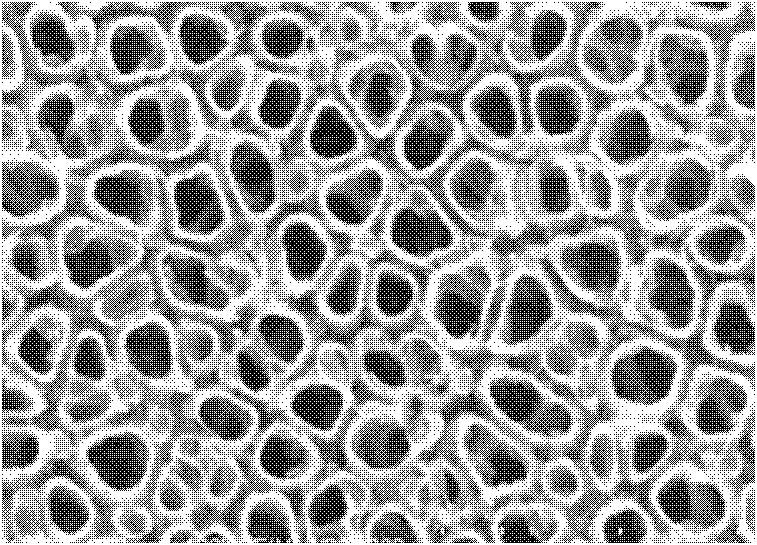

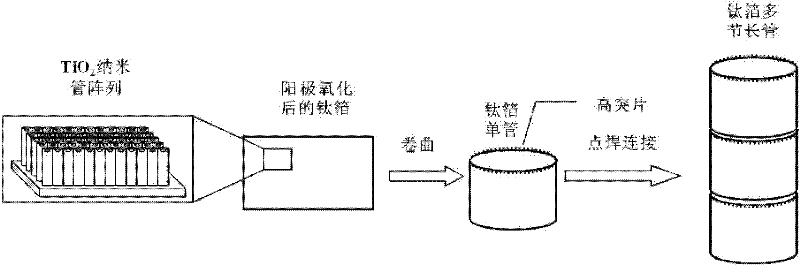

[0044] (1) Preparation of photocatalyst: measure a titanium metal foil with a length of 200 mm and a width of 200 mm. The surface is pretreated, and electrochemical anodic oxidation is carried out at room temperature. Titanium metal foil is used as the working electrode, stainless steel is used as the counter electrode, the electrode spacing is 5cm, the electrolyte is 0.3wt.% HF solution, the applied voltage is 10-30V, and an orderly layer can be built on the surface of the substrate after oxidation for 20 minutes. TiO 2 nanotube array film. After heat treatment at 450 DEG C, a one-dimensional ordered titanium dioxide nanotube array in anatase crystal form is obtained. figure 1 with figure 2 The field emission scanning electron microscope photograph of the titanium dioxide nanotube array on the titanium metal surface obtained in this example shows that the average diameter of the nanotubes is about 100 nm, and the tube length is 300-400 nm. , and evenly distributed ( f...

Embodiment 2

[0054] Embodiment 2: Using (1) photocatalyst and (2) photocatalytic reactor in embodiment 1, the initial pH value of proposed methyl orange is 3. Change the concentration of the dye solution, also adsorb for 1h, and after 2h of light, it is found that the lower the concentration of methyl orange, the higher the degradation rate of methyl orange ( Image 6 shown). However, compared with the oxidation by ultraviolet light, it was found that the higher the concentration of methyl orange, the more obvious the photocatalytic effect. When the initial concentration of methyl orange was 30mg / L, the photocatalytic degradation rate of methyl orange was 56.50%, and the photocatalytic efficiency increased by 113.85%.

Embodiment 3

[0055] Embodiment 3: Using (1) photocatalyst and (2) photocatalytic reactor in embodiment 1, the initial concentration of proposed base orange is 20mg / L, and initial pH value is 3. Adsorbed for 1 hour, degraded after 2 hours of light, and replaced with fresh methyl orange solution, and this cycle was carried out for continuous flow photocatalysis. It was found that the photocatalytic degradation rate of the methyl orange solution was still above 80.00% after the photocatalyst was used for 100 hours, which indicated that the photocatalytic activity could be stable for a long time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com