Process for producing hollow microspheres and process for producing porous molded ceramic

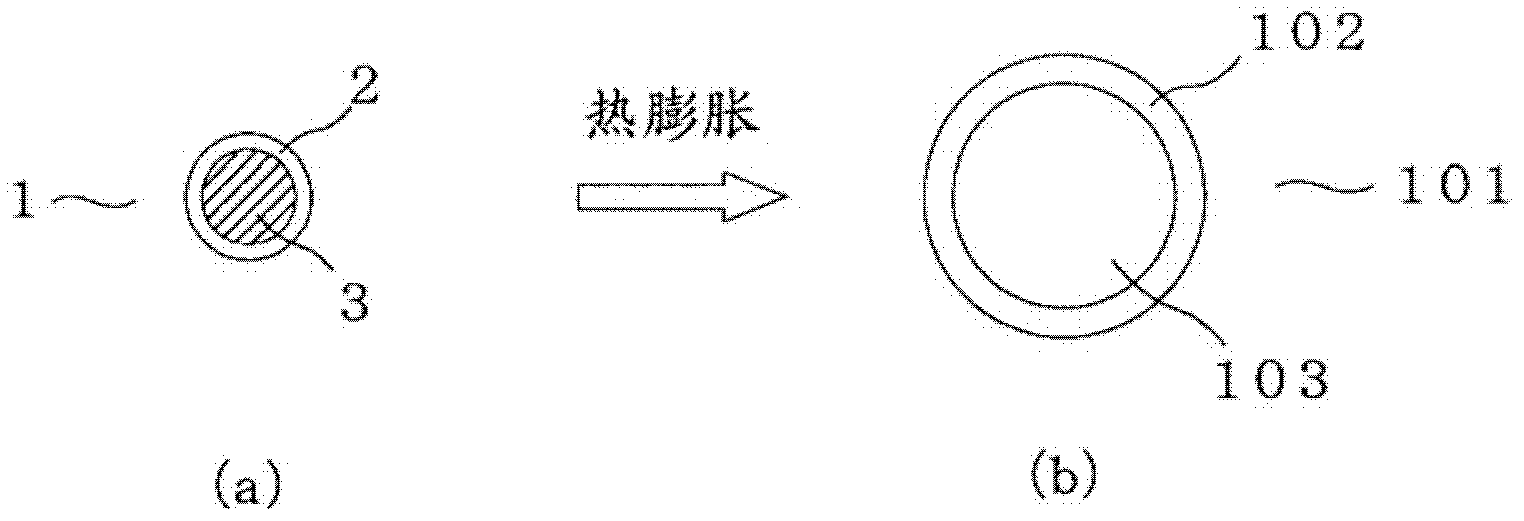

A manufacturing method and hollow technology, applied in the preparation of microspheres, ceramic products, microcapsule preparations, etc., can solve the problems of adhesion, dispersion stabilizer particles falling off, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

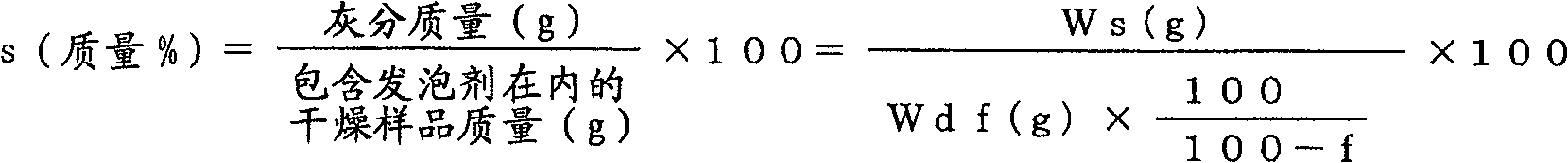

[0122] Examples and comparative examples are given below to describe the present invention more specifically, but the present invention is not limited to these examples. In the present invention, the measurement methods of physical properties and characteristics are as follows.

[0123] (1) Foaming ratio

[0124] 0.7 g of heat-expandable microspheres were placed in a Jill oven, and heated at a predetermined foaming temperature for 2 minutes to cause foaming (thermal expansion). The obtained hollow microspheres were put into a graduated cylinder, and the volume thereof was measured. The expansion ratio was calculated by dividing the volume of the hollow microspheres by the volume of the unexpanded heat-expandable microspheres. At this time, the foaming temperature was raised from 70° C. by 5° C. to foam at each temperature. The expansion ratio at the temperature at which the maximum expansion ratio was obtained under these conditions was defined as the maximum expansion rati...

Embodiment 1

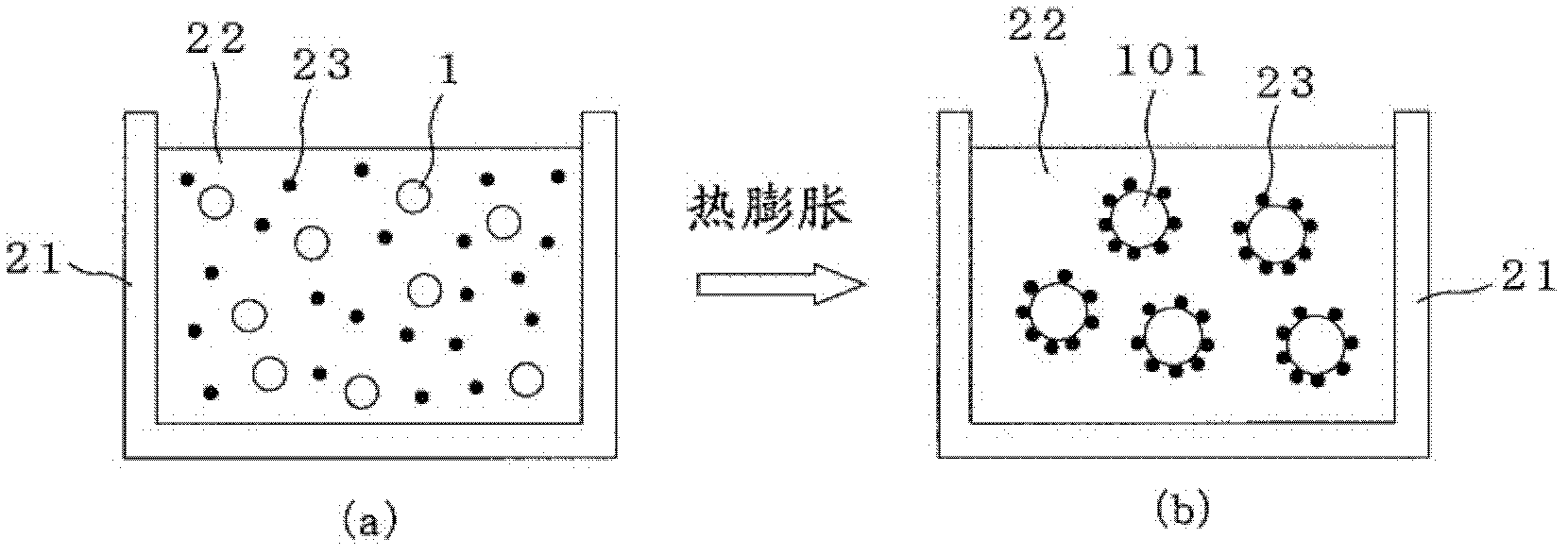

[0163] Deionized water was added to the heat-expandable microspheres obtained in Preparation Example 1 to prepare 500 g of an aqueous slurry having a concentration of 1% by mass of the heat-expandable microspheres. 40 g of colloidal calcium carbonate (average particle diameter 50 nm) was added to this aqueous slurry, and then added to a polymerization tank with a capacity of 1.5 liters with a stirrer. While stirring the aqueous slurry, steam heated to a temperature of 150° C. was blown thereinto at a pressure of 0.48 MPa to heat and expand the heat-expandable microspheres. In the aqueous slurry after the foaming treatment, the foam particles (hollow microspheres) are dispersed without forming aggregates.

[0164] The foam particles in the aqueous slurry are filtered and washed with water. Thereafter, washing with water and filtration were repeated twice, followed by drying to collect foam particles (hollow microspheres). The foam particles have an average particle diameter o...

Embodiment 2

[0166] Foam particles (hollow microspheres) were produced in the same manner as in Example 1, except that 100 g of colloidal silica (40% by mass of solid content, 12 nm in average particle diameter) was used instead of 40 g of colloidal calcium carbonate. The foam particles have an average particle diameter of 53 μm and a specific gravity of 0.10 g / cm 3 . The total content of the inorganic substances contained in the foam particles was 85% by mass. The hollow microspheres obtained in this way remarkably suppress scattering into the air, and are excellent in miscibility with inorganic substances having high specific gravity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com