Macrolattice mismatch epitaxial buffer layer structure containing digital dislocation separating layers and preparation method thereof

A technology of isolation layer and buffer layer, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of small and complex bandgap width, achieve low cost, simple preparation method, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] For epitaxy of In on InP substrates 0.8 Ga 0.2 Buffer Layer Structure Containing InGaAs Digital Alloy Dislocation Isolation Layer of As Large Lattice Mismatch Material

[0025] (1) It is high-quality In with a thicker epitaxial thickness on the InP substrate .8 Ga 0.2 As large lattice mismatch material, it needs to be in the epitaxial In .8 Ga 0.2 The buffer layer was grown before the As material;

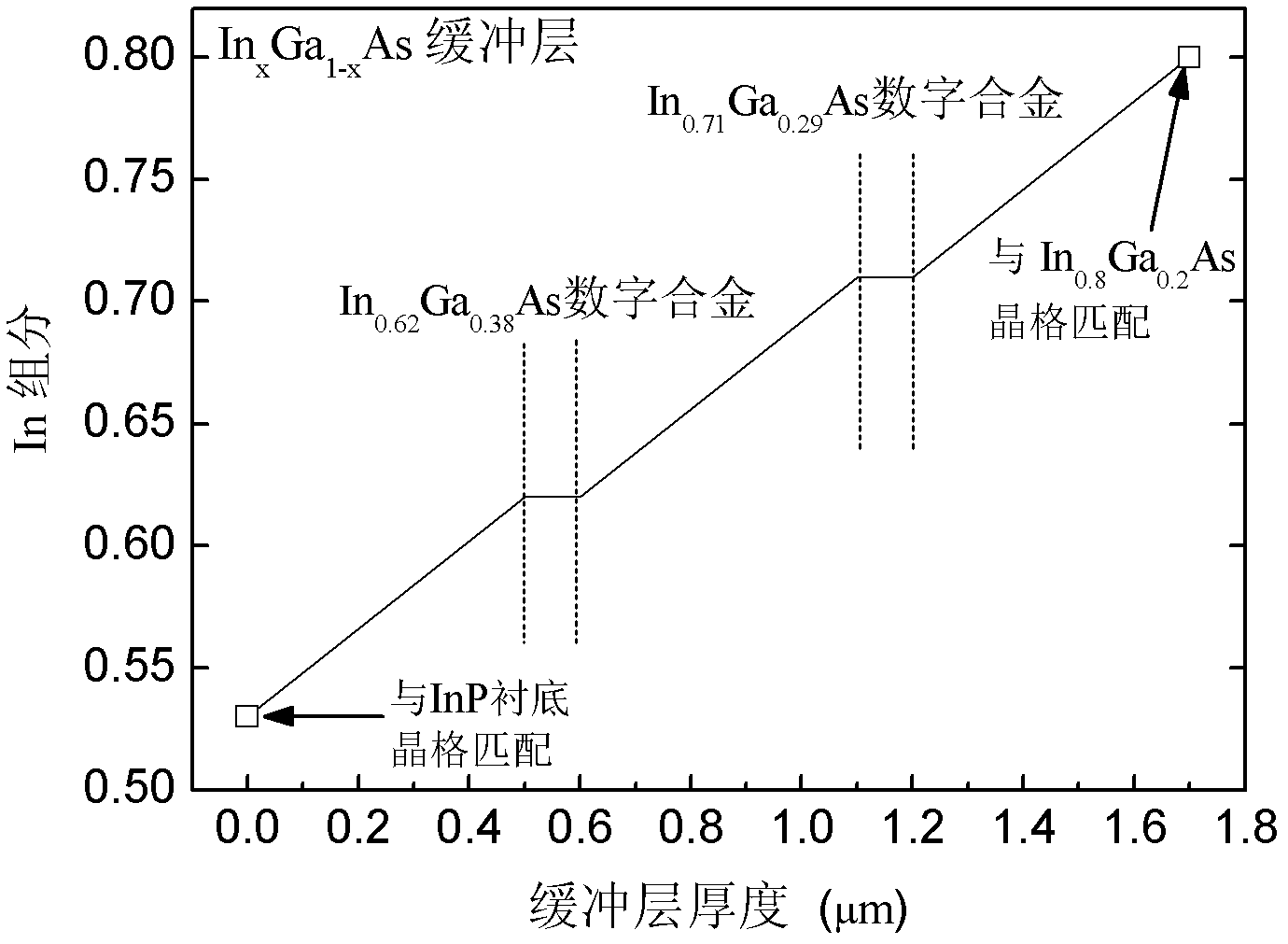

[0026] (2) The conventional molecular beam epitaxy method is used to grow the material, and the schematic diagram of the In composition change in the buffer layer structure is as follows figure 2 As shown, the schematic diagram of the buffer layer structure is shown in image 3 shown in the In x Ga 1-x Two layers of InGaAs digital alloys are inserted into the As composition gradient buffer layer, and the buffer layer is divided into 3 parts on average;

[0027] (3) The growth process of the buffer layer structure is composed of InP lattice-matched InP substrate 0....

Embodiment 2

[0034] For epitaxy of In on GaAs substrates 0.3 Al 0.7 Buffer Layer Structure Containing InAlAs Digital Alloy Dislocation Isolation Layer of As Large Lattice Mismatch Material

[0035] (1) High-quality In with thicker epitaxial thickness on GaAs substrate .3 Al 0.7 As large lattice mismatch material, it needs to be in the epitaxial In .3 Al 0.7 The buffer layer was grown before the As material;

[0036] (2) The conventional molecular beam epitaxy method is used to grow the material, and the schematic diagram of the In composition change in the buffer layer structure is as follows Figure 4 As shown, the schematic diagram of the buffer layer structure is shown in Figure 5 shown in the In x Al 1-x Two layers of InAlAs digital alloys are inserted into the As composition gradient buffer layer, and the buffer layer is divided into 3 parts on average;

[0037] (3) The growth process of the buffer layer structure starts with the growth parameters of the AlAs material lattic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com