Semiconductor eevice and manufacturing method thereof

A manufacturing method, semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as cracking at the junction, delamination of the dielectric layer, damage to the contact point device, etc., to reduce The effect of the delamination problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will provide many different embodiments to implement different features of the present invention. It is worth noting that these embodiments provide many possible inventive concepts that can be implemented in a wide variety of specific situations. However, the specific embodiments discussed herein are merely illustrative of the methods of making and using the invention, and are not intended to limit the scope of the invention.

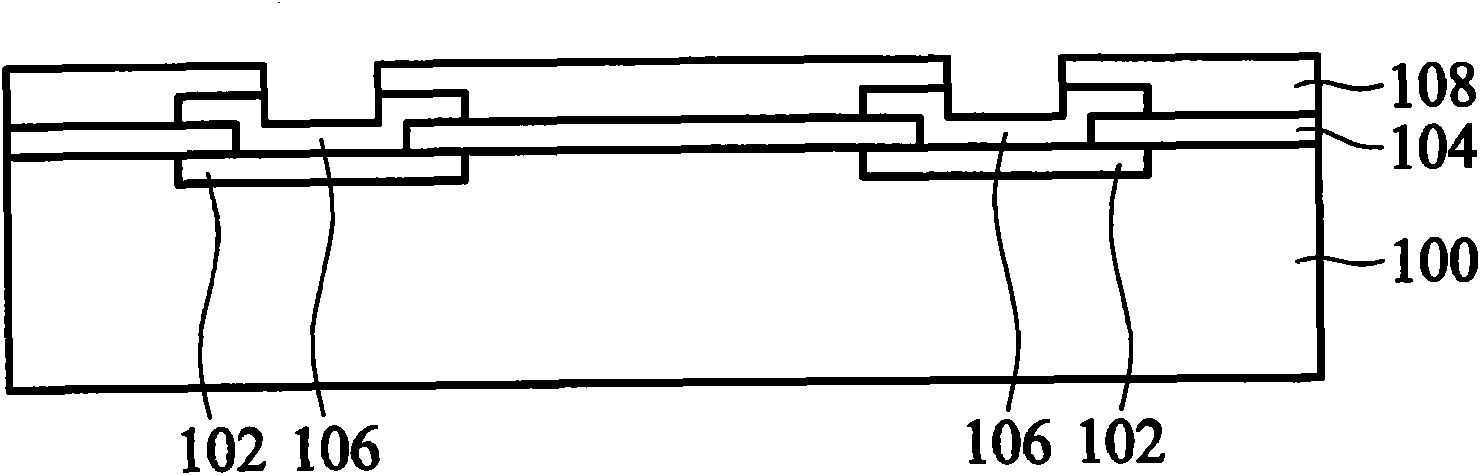

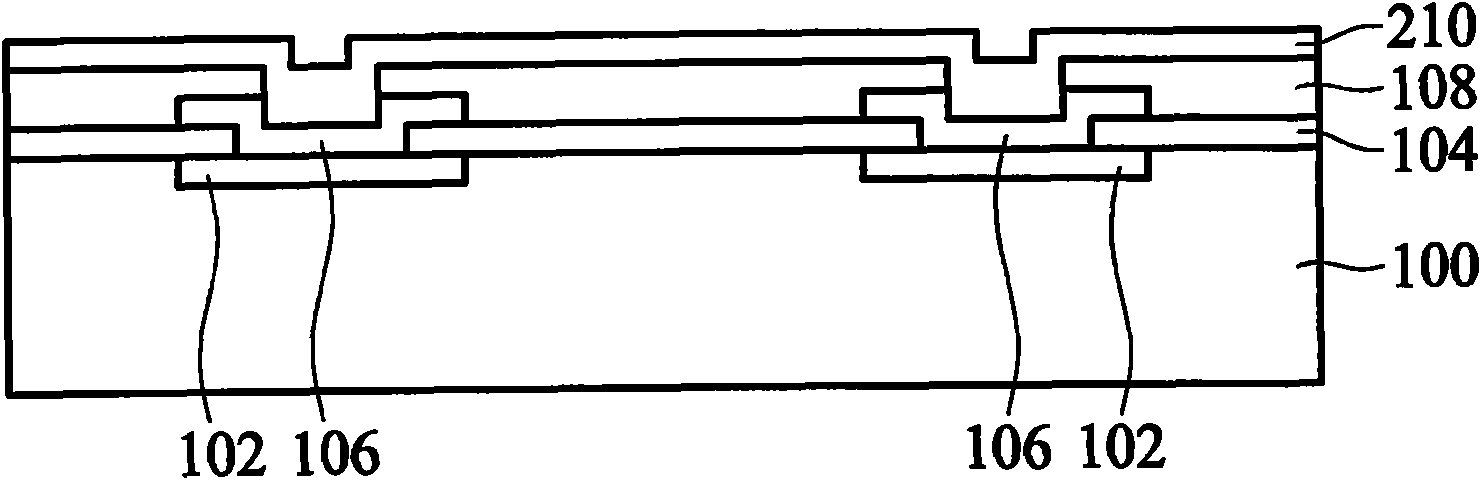

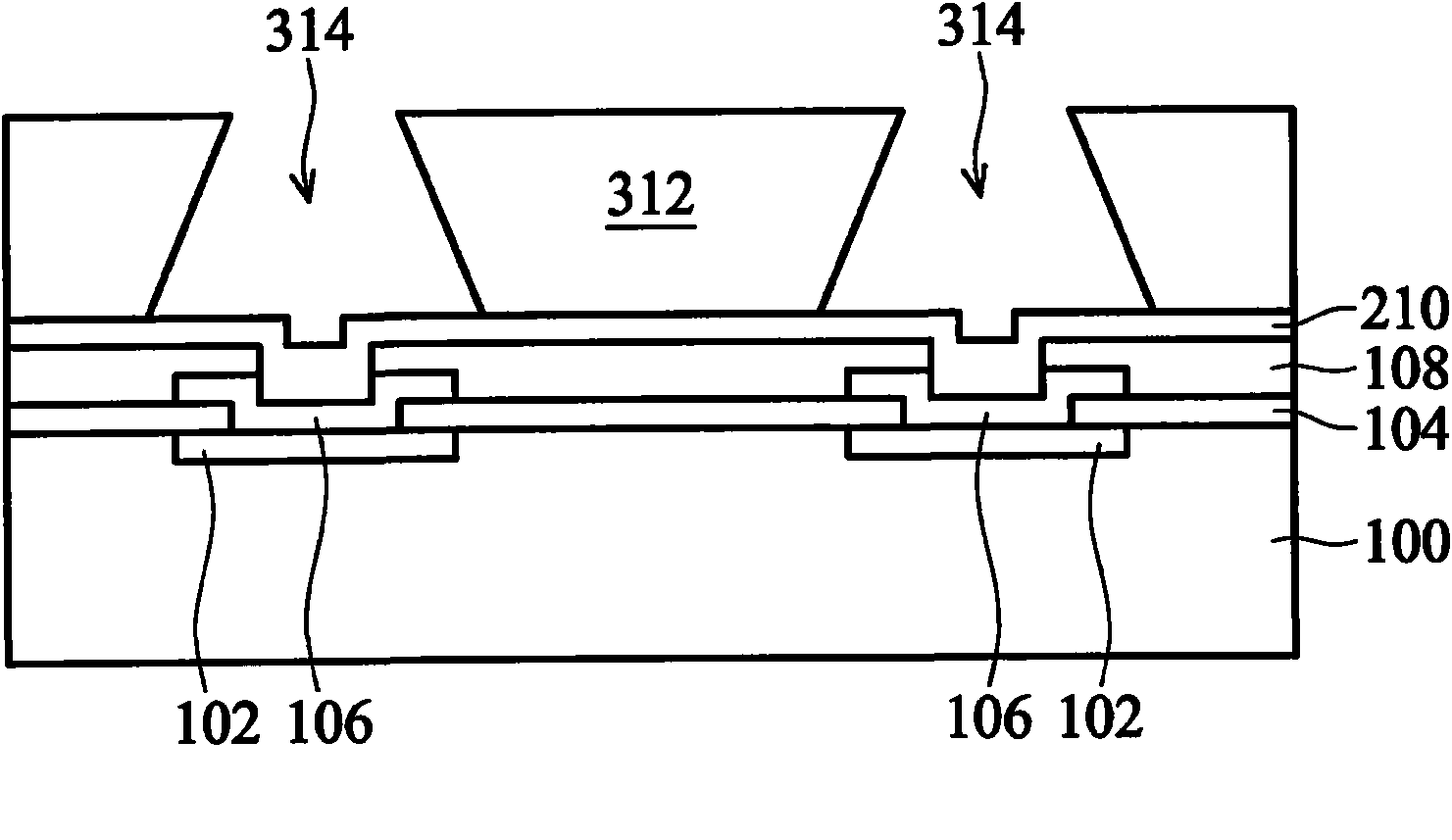

[0042] Embodiments described herein relate to the use of bumps or balls (commonly referred to herein as bumps) to interconnect one substrate to another, where each substrate can be an integrated circuit chip, a turntable Interposer, packaging substrate, printed circuit board, high-density interconnect, etc. Embodiments using trapezoidal bumps will be discussed in detail below, and it will be found that the embodiments discussed herein can reduce misalignment, thereby increasing yield and reliability. Various intermediate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com