Fused salt phase change heat storage device applied to solar air conditioner

A phase change heat storage, molten salt technology, applied in heat storage equipment, energy storage, indirect heat exchangers, etc., to achieve the effect of sufficient heat exchange process, good thermal conductivity, and large latent heat of phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

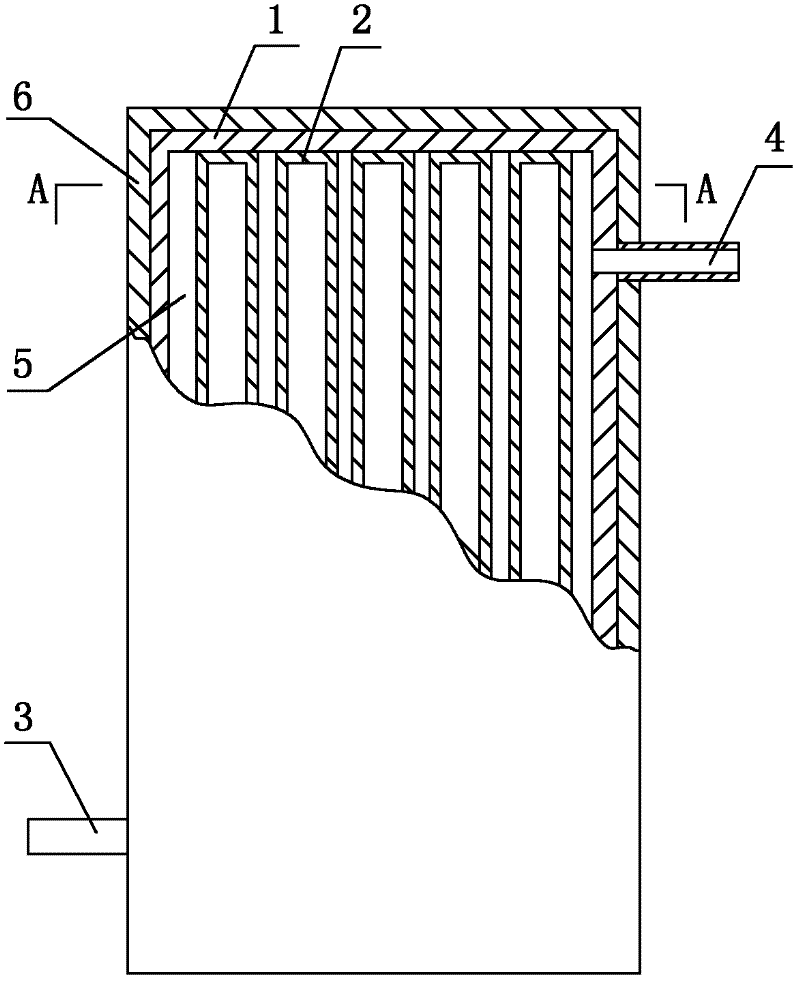

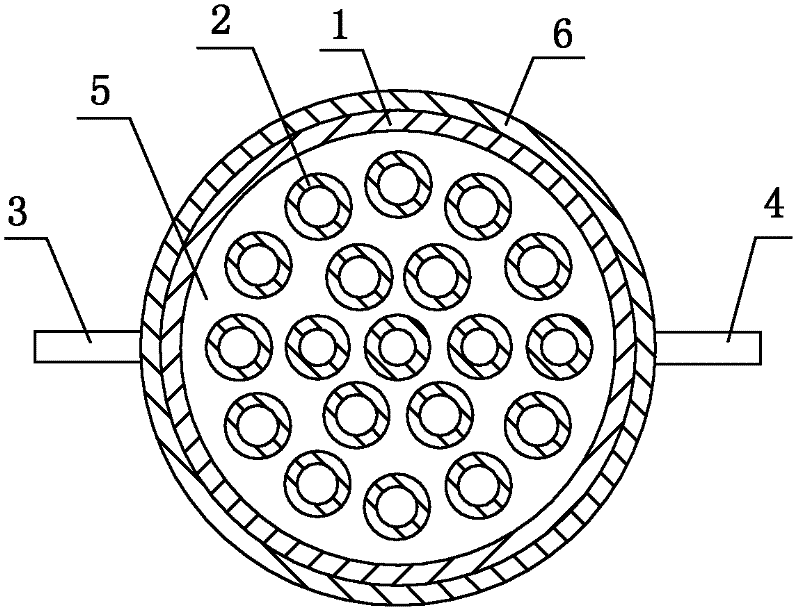

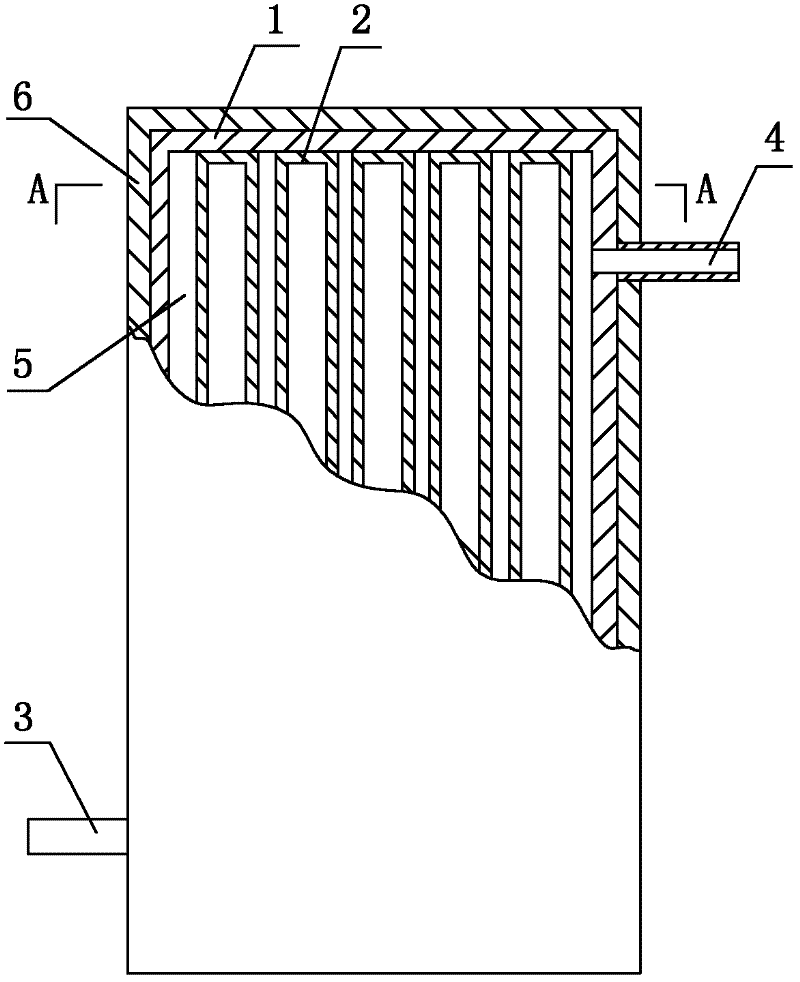

[0019] like figure 1 , figure 2 As shown in the figure, a molten salt phase change heat storage device applied to a solar air conditioner, which includes a heat storage chamber box 1, a heat storage material containing pipeline 2, a heat storage material, a thermal insulation layer 6 and a heat transfer oil; the heat storage chamber box 1 is the heat storage space 5 (except for the oil inlet 3 and the oil outlet 4, which is closed), and the heat storage chamber box 1 is provided with an oil inlet 3 and an oil outlet 4 (the oil inlet 3 is located at the The bottom of one side of the heat storage chamber box body 1, the oil outlet 4 is located at the top of the other side of the heat storage chamber box body 1), the oil inlet port 3 and the oil outlet port 4 are respectively connected with the heat storage space 5, and the heat storage chamber The heat storage space 5 of the box body 1 is provided with 2-200 heat storage material containing pipes 2 (the specific number is det...

Embodiment 2

[0031]Basically the same as Example 1, the difference is:

[0032] NaNO 3 / KaNO 3 The mass percentage of the raw material composition of graphite composite phase change heat storage material is: industrial NaNO 3 42.5%, industrial KaNO 3 42.5%, expanded graphite 15%. The specification of the stainless steel pipe is Φ133×3.

[0033] After the raw materials are evenly mixed with the ingredients, they are pressed into shape. The density of heat storage material is 1.80g / cm 3 , as measured by a differential scanning calorimeter (DSC), the latent heat per unit mass of the heat storage material is 111J / g, and the phase transition temperature is 210-220°C. The thermal conductivity of the heat storage material is 5.3 W / mK. After more than 200 cycle tests, the phase transition temperature basically remains unchanged, and the phase transition latent heat decline rate is only about 3%. Simulation calculations show that when the temperature of the heating oil is 280°C and the char...

Embodiment 3

[0035] Basically the same as Example 1, the difference is:

[0036] NaNO 3 / KaNO 3 The mass percentage of the raw material composition of graphite composite phase change heat storage material is: industrial NaNO 3 45%, Industrial KaNO 3 45%, expanded graphite 10%. The specification of the stainless steel pipe is Φ127×3.

[0037] After the raw materials are evenly mixed with the ingredients, they are pressed into shape. The density of heat storage material is 1.85g / cm 3 , as measured by a differential scanning calorimeter (DSC), the latent heat per unit mass of the heat storage material is 115J / g, and the phase transition temperature is 210-220°C. The thermal conductivity of the heat storage material is 3.2W / mK. After more than 200 cycle tests, the phase transition temperature basically remains unchanged, and the phase transition latent heat decline rate is only about 3%. The simulation calculations show that when the temperature of the heating oil is 280°C and the char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com