Washing and drying integrated machine for washing clothes by adopting water heated by heat pump

A technology for making hot water and an all-in-one machine, applied in the field of washing machines, can solve problems such as endangering personal safety, accidental fire, rupture of heating tube shells, etc., and achieve the effects of shortening drying time, improving condensation efficiency and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

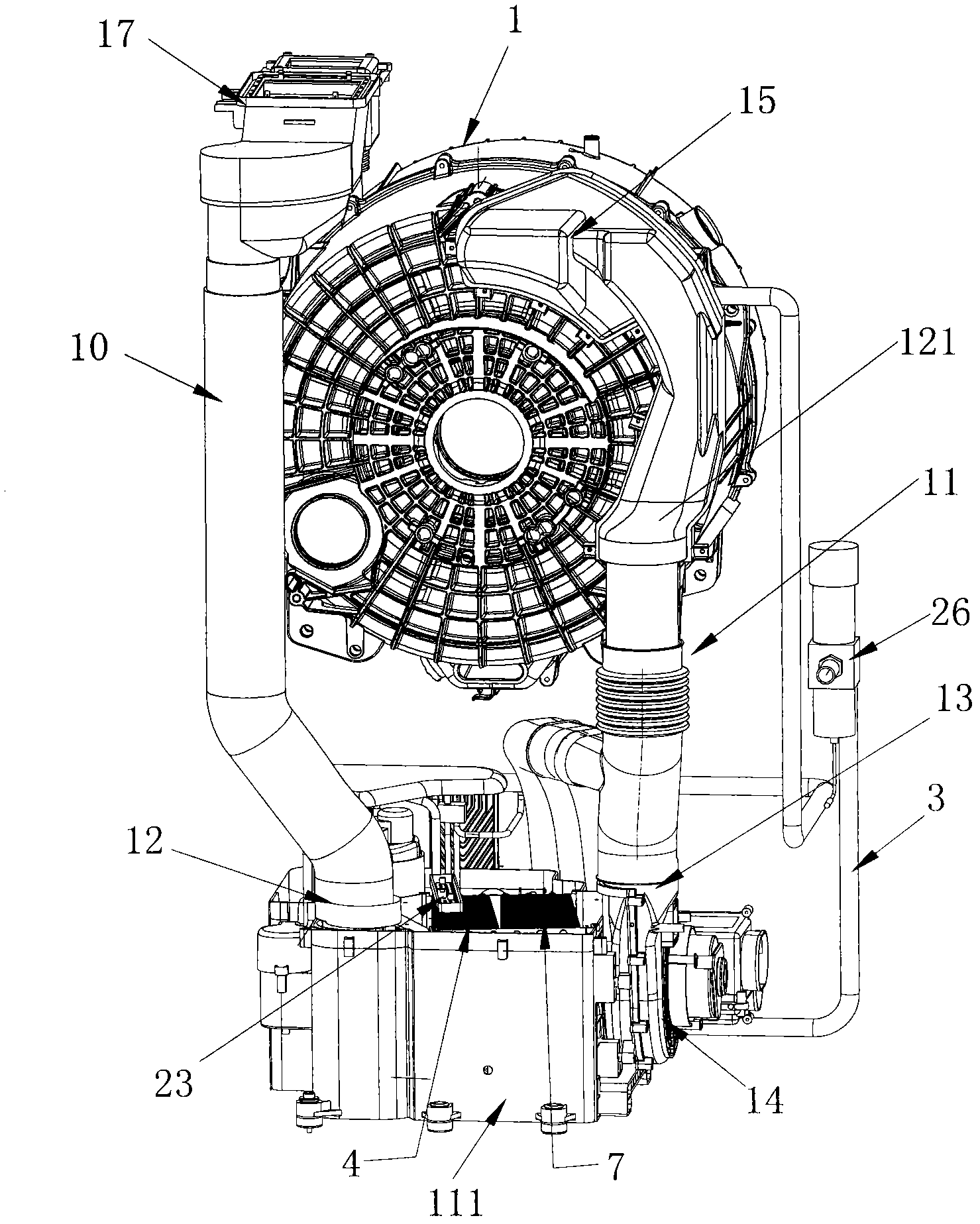

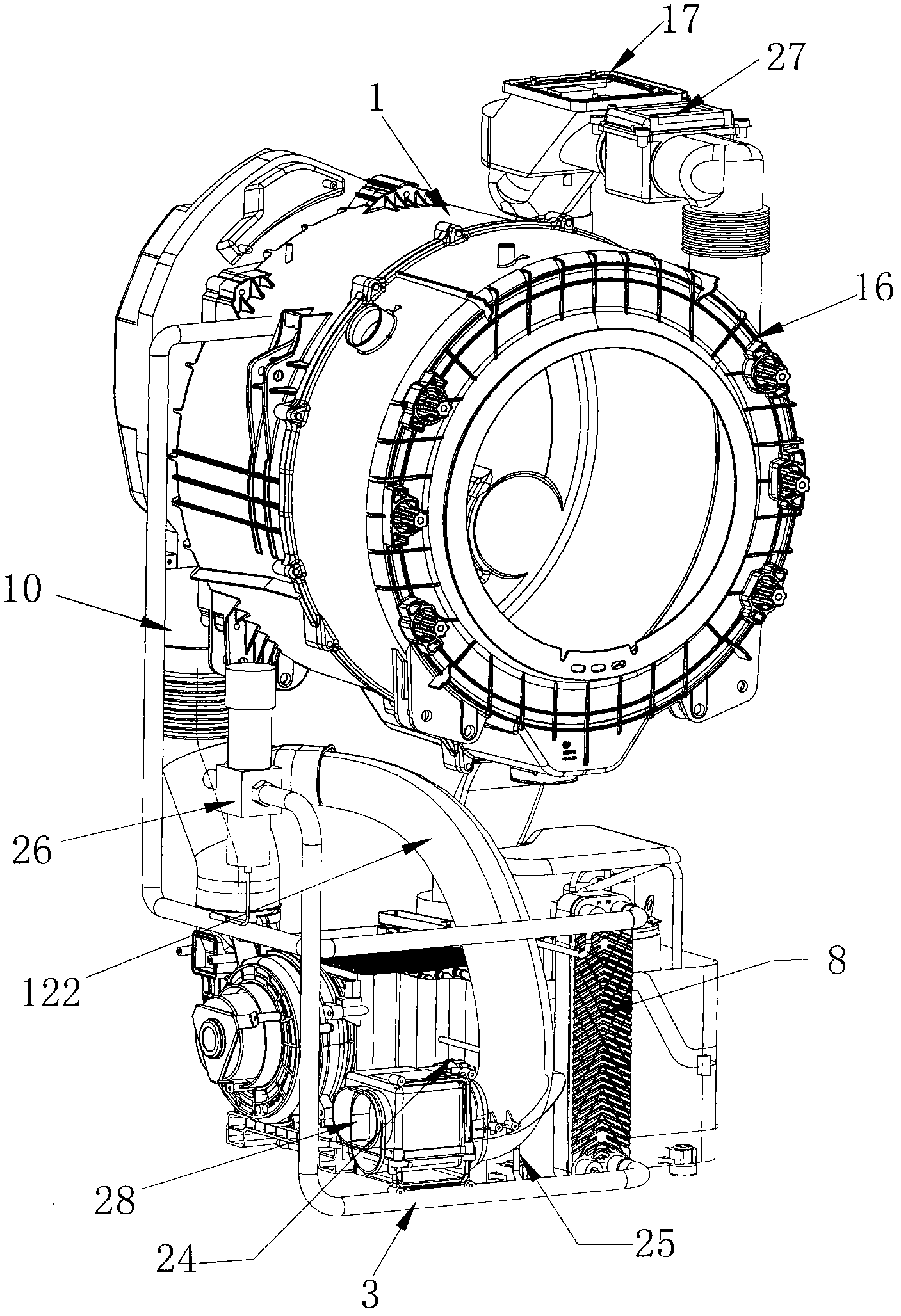

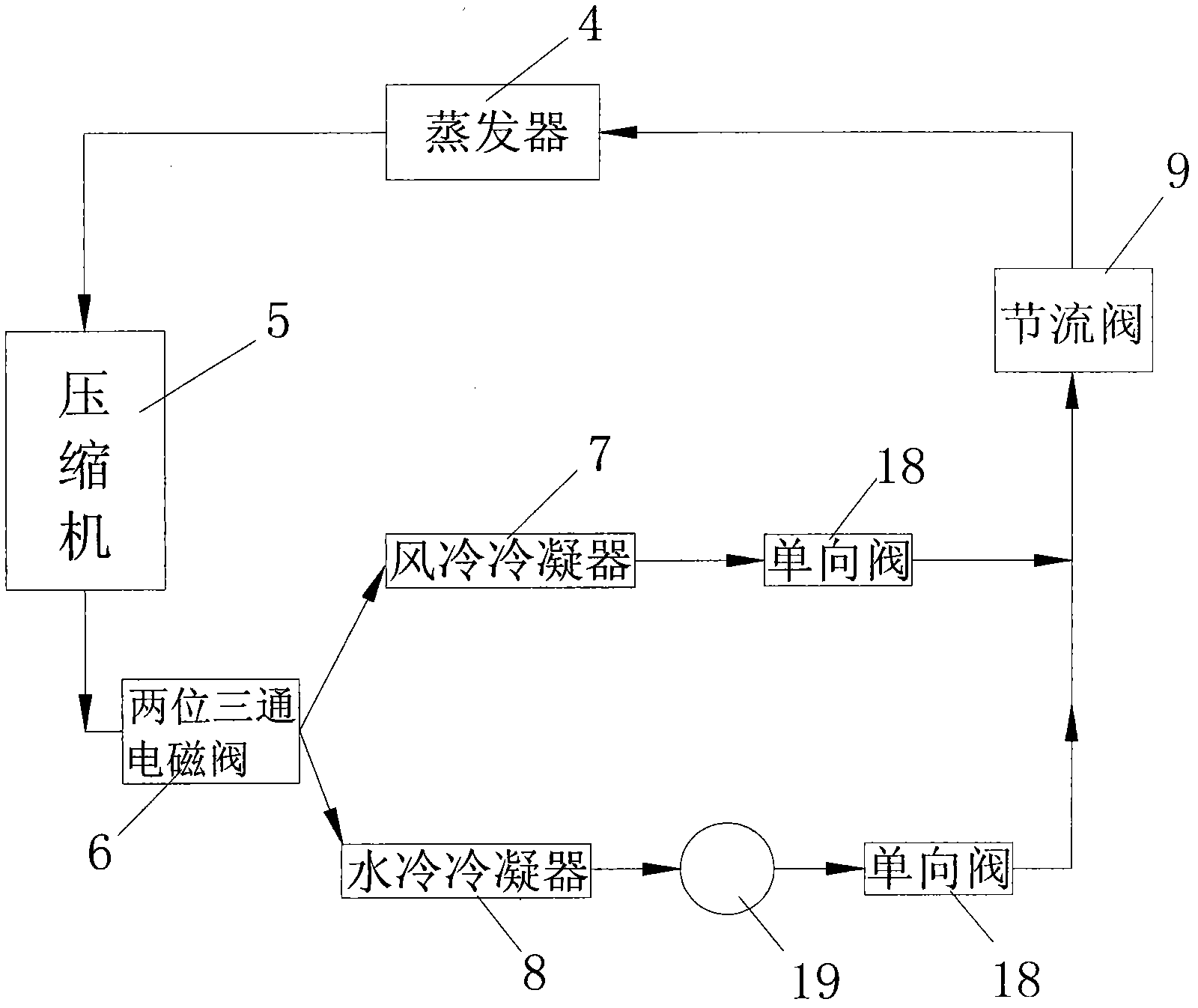

[0040] Such as Figure 1 to Figure 9 As shown, an integrated washing and drying machine using a heat pump to prepare hot water for laundry according to the present invention includes an outer cylinder 1, an inner cylinder 2 coaxially arranged inside the outer cylinder, a heat pump system, and a water inlet pipeline 3. The heat pump The system includes an evaporator 4, a compressor 5, a two-position three-way solenoid valve 6, a condenser group composed of an air-cooled condenser 7 and a water-cooled condenser 8 connected in parallel, and a throttle valve 9, an evaporator 4, a compressor 5, two Position three-way solenoid valve 6, condenser group, throttle valve 9 and then evaporator 4 are connected in series to form a circulation system (refer to image 3 ); the water inlet pipeline 3, the heat pump system and the outer cylinder 1 form a hot water heating system, and the outer cylinder 1 and the heat pump system are connected through two sections of air ducts 10 and 11 to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com