Preparation method of technical grade kasumin

A kasugamycin and pulping technology, which is applied in the field of kasugamycin technical preparation, can solve problems such as low yield of the raw medicine, and achieve the effects of simple and easy method, overcoming melting and sticking walls, and simple and easy production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

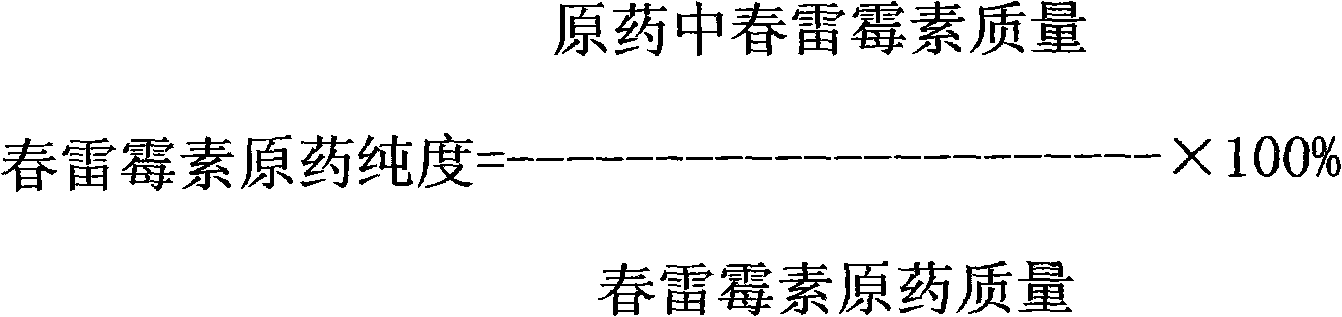

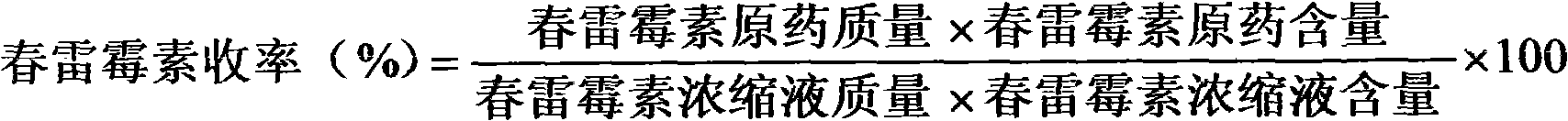

Image

Examples

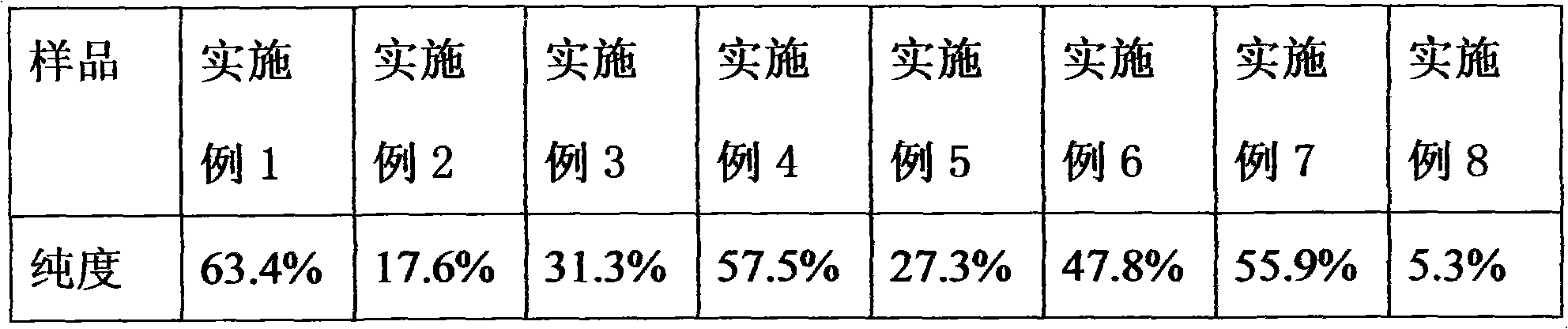

Embodiment 1

[0047] Streptomyces aureus fermentation broth was filtered to remove mycelia, and the pH value of the filtrate was adjusted to 3.5 with hydrochloric acid. The vacuum film concentrator concentrated the filtrate to make the content of kasugamycin 3.0%. When concentrating, the vacuum degree was -0.09Mpa and the temperature was 70°C , weighing kasugamycin fermentation filtrate 1000kg, kaolin 10kg. First add the above-mentioned kasugamycin concentrated filtrate in the open stirred tank, then start stirring, and control the rotating speed to be 50r / min. Add kaolin to the filtrate, and evenly add kaolin at a speed of 1 kg per minute under the condition of the paddle rotation speed of 50 r / min to make a slurry. The slurry enters the preheated spray drying tower for spray drying, and the temperature of the air inlet is adjusted to maintain the temperature inside the tower at 95°C during spray drying. After spray drying, the powder collected by the spray drying tower collector is off-w...

Embodiment 2

[0049]Streptomyces aureus fermented liquid was filtered to remove mycelia, and the pH value of the filtrate was adjusted to 2 with hydrochloric acid, and the vacuum film concentrator concentrated the filtrate so that the content of kasugamycin was 1.5%. When concentrating, the vacuum degree was -0.09Mpa, and the temperature was 50°C , weighing kasugamycin fermentation filtrate 1000kg, diatomaceous earth 50kg. First add the above-mentioned kasugamycin concentrated filtrate in an open stirred tank. Then start stirring, and the control speed is 70r / min. Diatomite was added to the filtrate, and diatomite was evenly added at a speed of 1 kg per minute under the condition of the paddle rotation speed of 70 r / min to form a slurry. The slurry enters the preheated spray drying tower for spray drying, and the temperature of the air inlet is adjusted to maintain the temperature inside the tower at 95°C during spray drying. After spray drying, the powder collected by the spray drying to...

Embodiment 3

[0051] Streptomyces aureus fermented liquid was filtered to remove mycelia, and the pH value of the filtrate was adjusted to 2 with hydrochloric acid. The vacuum film concentrator concentrated the filtrate so that the content of kasugamycin was 2.0%, and the vacuum degree was -0.09Mpa during concentration, and the temperature was 70°C , weighing kasugamycin fermentation filtrate 1000kg, diatomaceous earth 30kg. First add the above-mentioned kasugamycin concentrated filtrate in an open stirred tank. Then start stirring, and the control speed is 70r / min. Diatomite was added to the filtrate, and diatomite was evenly added at a speed of 1 kg per minute under the condition of the paddle rotation speed of 70 r / min to form a slurry. The slurry enters the preheated spray drying tower for spray drying, and the temperature of the air inlet is adjusted to maintain the temperature inside the tower at 95°C during spray drying. After spray drying, the powder collected by the spray drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com