Carbon/carbon : titanium carbide nanometer multilayer film plated on surface of all-metal joint head and acetabular cup

A nano-multi-layer, joint head technology, applied in coatings, medical science, tissue regeneration, etc., to achieve the effect of improving interface bonding force, chemical inertness and corrosion resistance, improving interface bonding force and load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

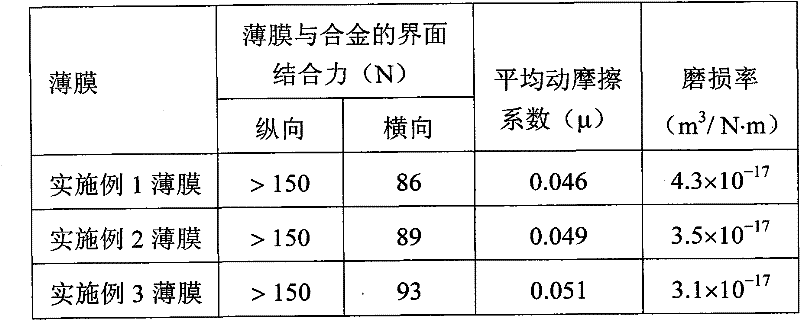

Embodiment 1

[0016] A closed-field unbalanced magnetron sputtering device was used to sputter and deposit nanometer multilayer films on the surface of titanium alloy joint head and alloy acetabular cup. Co-sputtering of high-purity graphite targets and graphite: metal Ti composite targets was placed in four directions perpendicular to the horizontal and 90 degrees to each other to prepare thin films. The No. 1 and No. 3 targets are graphite targets, and the No. 2 and No. 4 targets are graphite: metal Ti composite targets. Graphite: The content of Ti in the metal Ti composite target is 2% (Ti / graphite area ratio), which is evenly distributed and embedded in the graphite target matrix. The turret on which the alloy joint head or alloy acetabular cup specimen is placed is rotated around the vertical center in a single axis, and the rotational speed of the turret is controlled at 1.5rpm. The sample tilts and oscillates and rotates at the same time, and the distance between the sample and the ...

Embodiment 2

[0019] A closed-field unbalanced magnetron sputtering device was used to sputter and deposit nano-multilayer composite films on the surface of titanium alloy joint head and alloy acetabular cup. Co-sputtering of high-purity graphite targets and graphite: metal Ti composite targets was placed in four directions perpendicular to the horizontal and 90 degrees to each other to prepare thin films. The No. 1 and No. 3 targets are graphite targets, and the No. 2 and No. 4 targets are graphite: metal Ti composite targets. Graphite: The content of Ti in the metal Ti composite target is 2% (Ti / graphite area ratio), which is evenly distributed and embedded in the graphite target matrix. The turret on which the alloy joint head or the alloy acetabular cup specimen is placed is rotated on a single axis around the vertical center, and the rotational speed of the turret is controlled at 2rpm. The test piece tilts and swings and rotates at the same time, and the distance between the test pie...

Embodiment 3

[0022] A closed-field unbalanced magnetron sputtering device was used to sputter and deposit nano-multilayer composite films on the surface of titanium alloy joint head and alloy acetabular cup. Co-sputtering of high-purity graphite targets and graphite: metal Ti composite targets was placed in four directions perpendicular to the horizontal and 90 degrees to each other to prepare thin films. The No. 1 and No. 3 targets are graphite targets, and the No. 2 and No. 4 targets are graphite: metal Ti composite targets. Graphite: The content of Ti in the metal Ti composite target is 2% (Ti / graphite area ratio), which is evenly distributed and embedded in the graphite target matrix. The turret on which the alloy joint head or the alloy acetabular cup specimen is placed is rotated on a single axis around the vertical center, and the rotational speed of the turret is controlled at 3rpm. The test piece tilts and swings and rotates at the same time, and the distance between the test pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com