In-situ test system of strong laser beam quality

A technology of beam quality and in-situ detection, applied in photometry, optical radiation measurement, instruments, etc., can solve the problems of laser re-inspection and inability to detect with optical system, and achieve the effect of improving generation ability and anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

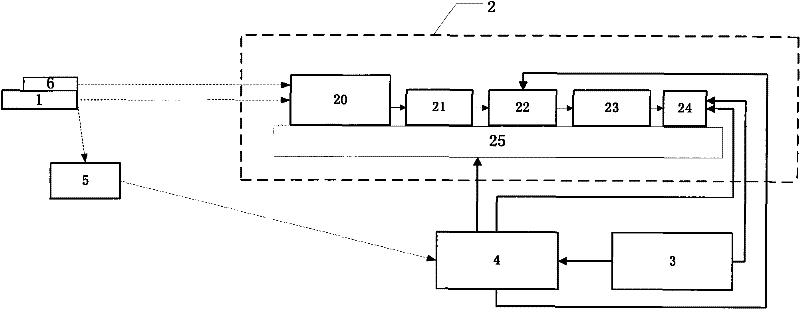

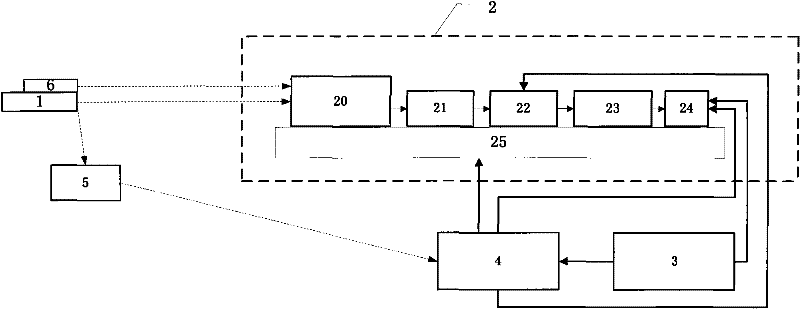

[0014] Strong laser beam quality in-situ detection system, such as figure 1 As shown, it is characterized in that the system consists of an optical measuring head unit 2 , an information processing computer 3 , a main control electric box 4 , a scattering receiving system 5 and an indicating laser 6 . The optical measuring head unit 2 is composed of an adaptive optical system 20 , a beam reduction system 21 , an electro-optic attenuation 22 , a microlens array 23 , a CCD 24 and a precise two-dimensional adjustment platform 25 .

[0015] The optical measuring head unit 2 is a receiving device used to measure the beam quality of a strong laser, and the adaptive optical system 20, the beam reduction system 21, the electro-optical attenuation 22, the microlens array 23 and the CCD 24 are all fixed on the precise two-dimensional adjustment platform 25 above, and sequentially coaxial mechanical connection; the laser beam emitted by the test object 1 first enters the adaptive optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com