Preparation method of biodegradable polymer foamed sheet product

A foamed sheet, biodegradable technology, applied in the field of preparation of biodegradable polymer foamed sheet products, can solve the problems of difficult PLA foaming materials, unstable production process, increased material cost, etc., and achieve mechanical properties. Excellent, excellent temperature resistance, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

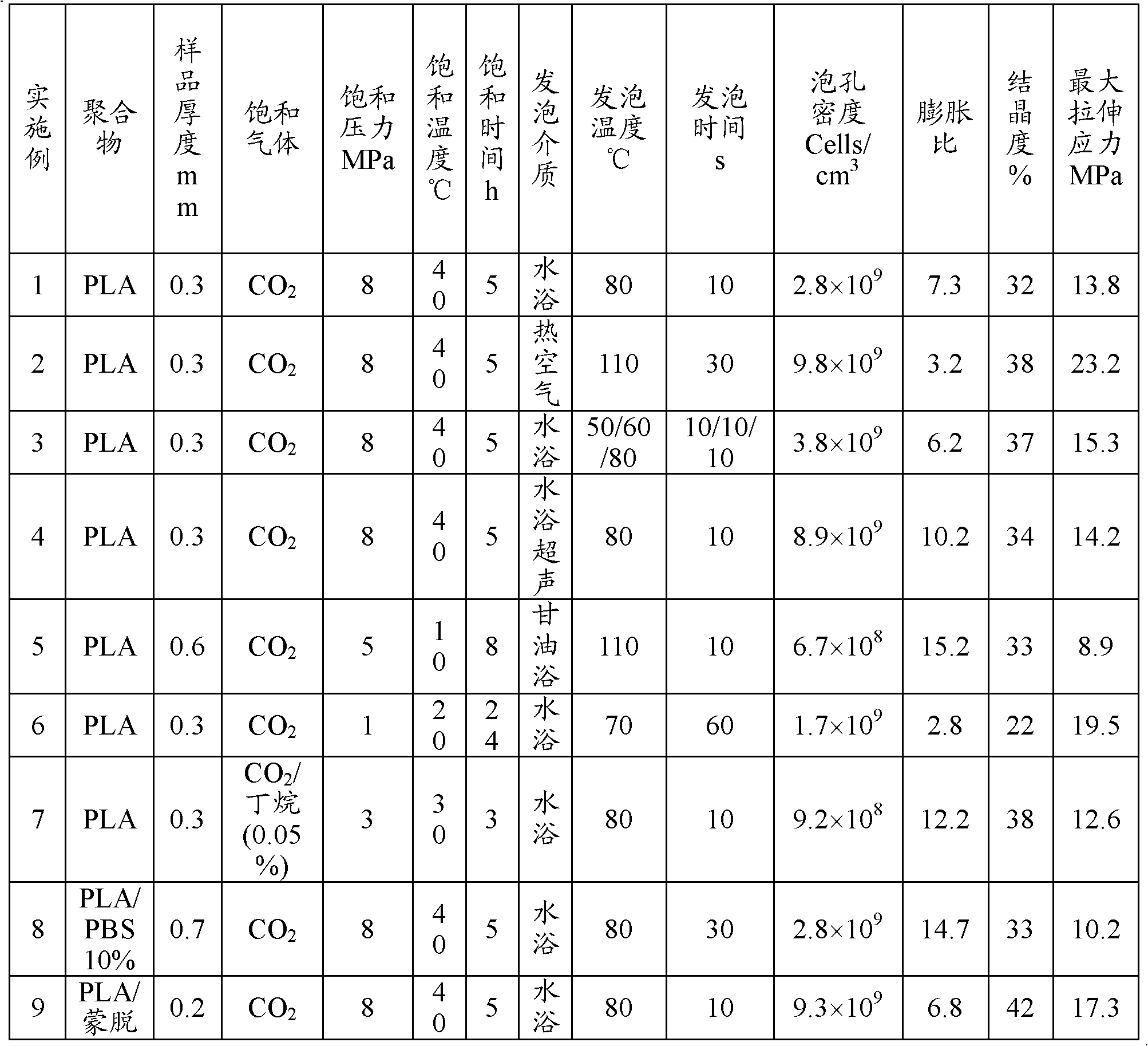

Embodiment 1

[0036] Add semi-crystalline PLA (the product of NaureWorks company, the weight percentage of D-type lactic acid monomer in PLA resin is 4.2%) to the single-screw extruder, and the PLA melt is transported to the extruder through single-screw extrusion Die opening, extrusion of PLA melt and drawing to prepare a PLA sheet with a thickness of 0.3 mm.

[0037] The prepared PLA sheet is put into an autoclave, and a high-pressure CO with a pressure of 8 MPa is introduced. 2 Fluid, make the PLA sheet reach saturation, the saturation temperature is 40°C, the saturation time is 5h, and the saturated PLA sheet is obtained. The saturated polylactic acid sheet was foamed in a water bath at 80° C. for 10 seconds to obtain a PLA microfoamed sheet.

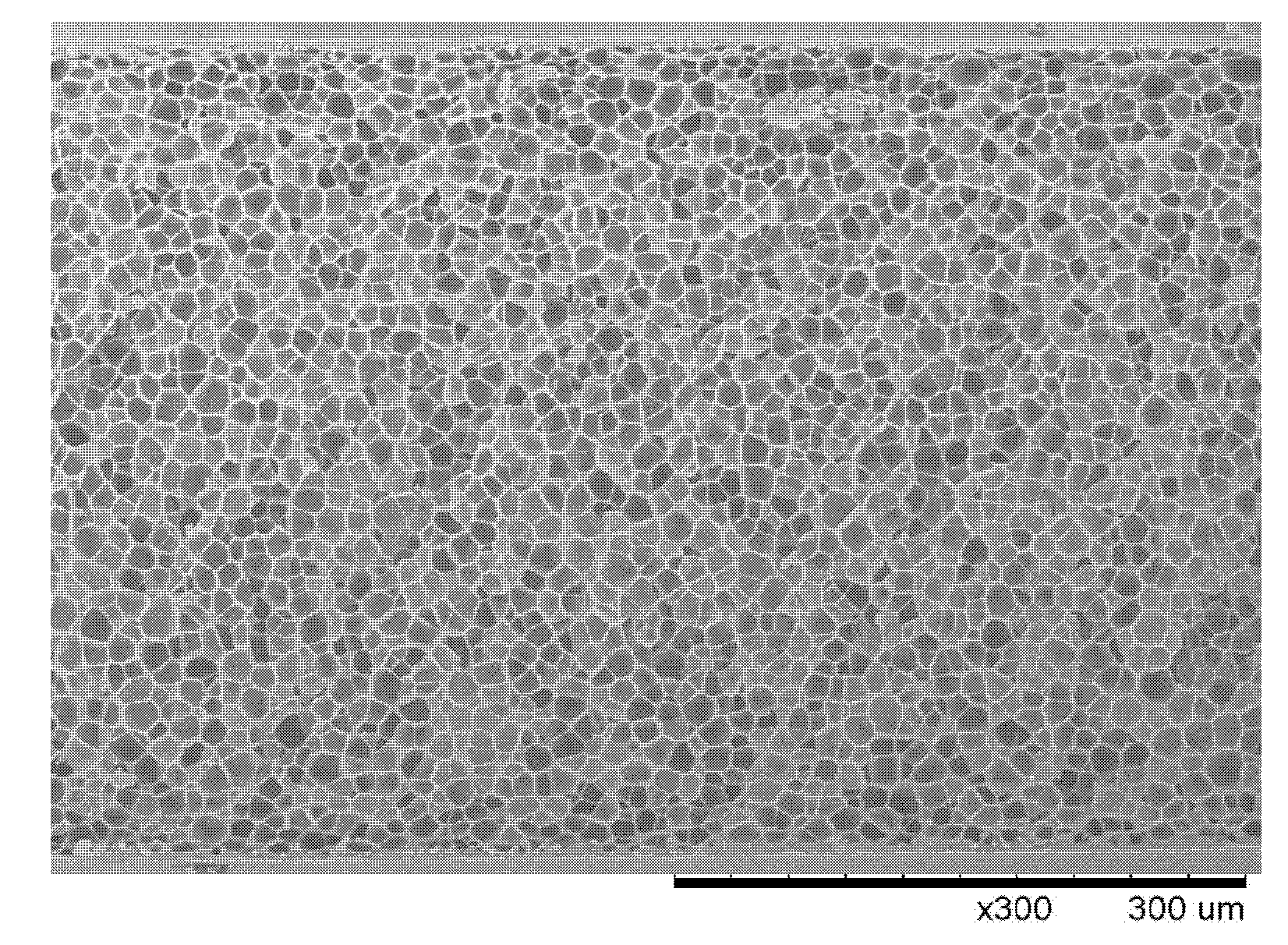

[0038] The prepared PLA microfoamed sheet has a smooth and smooth appearance structure. Scanning electron microscope analysis was carried out on the quenched section of the PLA microfoamed sheet sample, such as figure 1 As shown, it shows that...

Embodiment 2

[0042] Except that the foaming heating medium of the PLA sheet uses hot air at 110°C and the foaming time is 30s, other operations are the same as in Example 1, and PLA microfoamed sheets and biodegradable polylactic acid microfoamed sheet products are obtained . The prepared PLA microfoamed sheet has a smooth and smooth appearance structure. The scanning electron microscope analysis of the quenched section of the PLA micro-foamed sheet sample shows that the cell structure of the PLA micro-foamed sheet is evenly distributed, and the cell density is 9.8×10 9 cells / cm 3 , the expansion ratio is 3.2. The differential scanning calorimeter (DSC) test shows that: the crystallinity of the PLA microfoamed sheet is 38%, and the crystallinity of the biodegradable polylactic acid microfoamed sheet product is 47%. The research of the tensile testing machine shows that the maximum tensile stress of the biodegradable polylactic acid microfoamed sheet is 23.2MPa, and the maximum tensile s...

Embodiment 3

[0044] Except that the PLA sheet is foamed in a water bath at 50°C for 10s, then foamed in a water bath at 60°C for 10s, and then foamed in a water bath at 80°C for 10s, the other operations are the same as in Example 1 to prepare PLA microsheets. Foamed sheets and biodegradable polylactic acid microfoamed sheet products. The prepared PLA microfoamed sheet has a smooth and smooth appearance structure. The scanning electron microscope analysis of the quenched section of the PLA micro-foamed sheet sample shows that the cell structure of the PLA micro-foamed sheet is evenly distributed, and the cell density is 3.8×10 9 cells / cm 3 , the expansion ratio is 6.2. The differential scanning calorimeter (DSC) test shows that: the crystallinity of the PLA microfoamed sheet is 37%, and the crystallinity of the biodegradable polylactic acid microfoamed sheet product is 48%. The research of the tensile testing machine shows that the maximum tensile stress of the biodegradable polylactic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com